When it comes to maintaining and repairing outdoor power tools, having a clear visual reference for their internal structure is crucial. A detailed visual map can simplify the process of identifying parts, understanding their functions, and troubleshooting issues effectively.

Whether you’re a professional or a hobbyist, knowing how to navigate the individual components of your machine can save you time and effort. By using a comprehensive visual guide, you can easily pinpoint the source of any malfunction and address it with precision. This approach ensures that you maintain the tool in optimal working condition for longer periods.

In this guide, we will explore how to use these valuable resources to enhance your understanding and improve the efficiency of your maintenance tasks. With the right reference, you’ll gain confidence in performing repairs and replacing worn-out parts as needed.

Understanding the Components of Your Equipment

Knowing the internal structure of your outdoor equipment is essential for effective maintenance and troubleshooting. A clear understanding of each part’s role helps in diagnosing issues and performing repairs. By recognizing the function of every individual piece, you ensure that your tool operates smoothly and efficiently over time.

In this section, we will explore the key components that make up your machine. Understanding how these elements work together is vital for anyone looking to perform repairs or simply improve their tool knowledge.

- Engine: The heart of the machine, responsible for driving all other components. Understanding its function is crucial for maintenance and repairs.

- Fuel System: Comprising the fuel tank, lines, and filters, this system ensures the engine receives the necessary power to run smoothly.

- Air Intake: Filters and intake valves that control airflow to the engine, directly impacting performance and fuel efficiency.

- Exhaust System: Responsible for expelling gases from the engine. Keeping this system in good condition is essential to avoid overheating.

- Drive Mechanism: This includes the parts responsible for transferring power from the engine to the working components, like fans or cutting tools.

- Control Unit: Includes switches, levers, and buttons that allow the user to control the machine’s functions with ease.

By familiarizing yourself with these components, you can address issues more efficiently and keep your tool in peak condition for every job.

How to Use the Visual Breakdown Effectively

Having a visual guide of your equipment’s internal layout is an invaluable resource for maintaining and repairing your tool. By understanding how to interpret this reference, you can easily identify each component, determine where issues lie, and streamline your repair efforts. This guide will show you how to make the most of these visual resources to enhance your maintenance tasks.

Step-by-Step Guide to Interpreting the Visual Reference

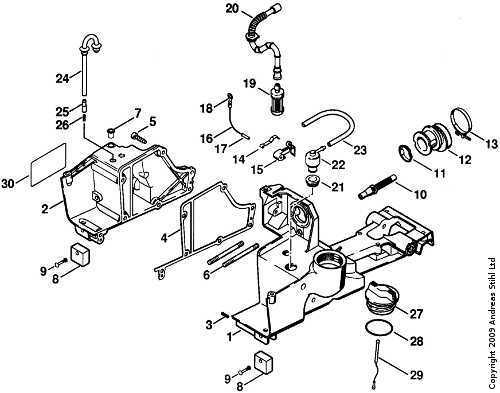

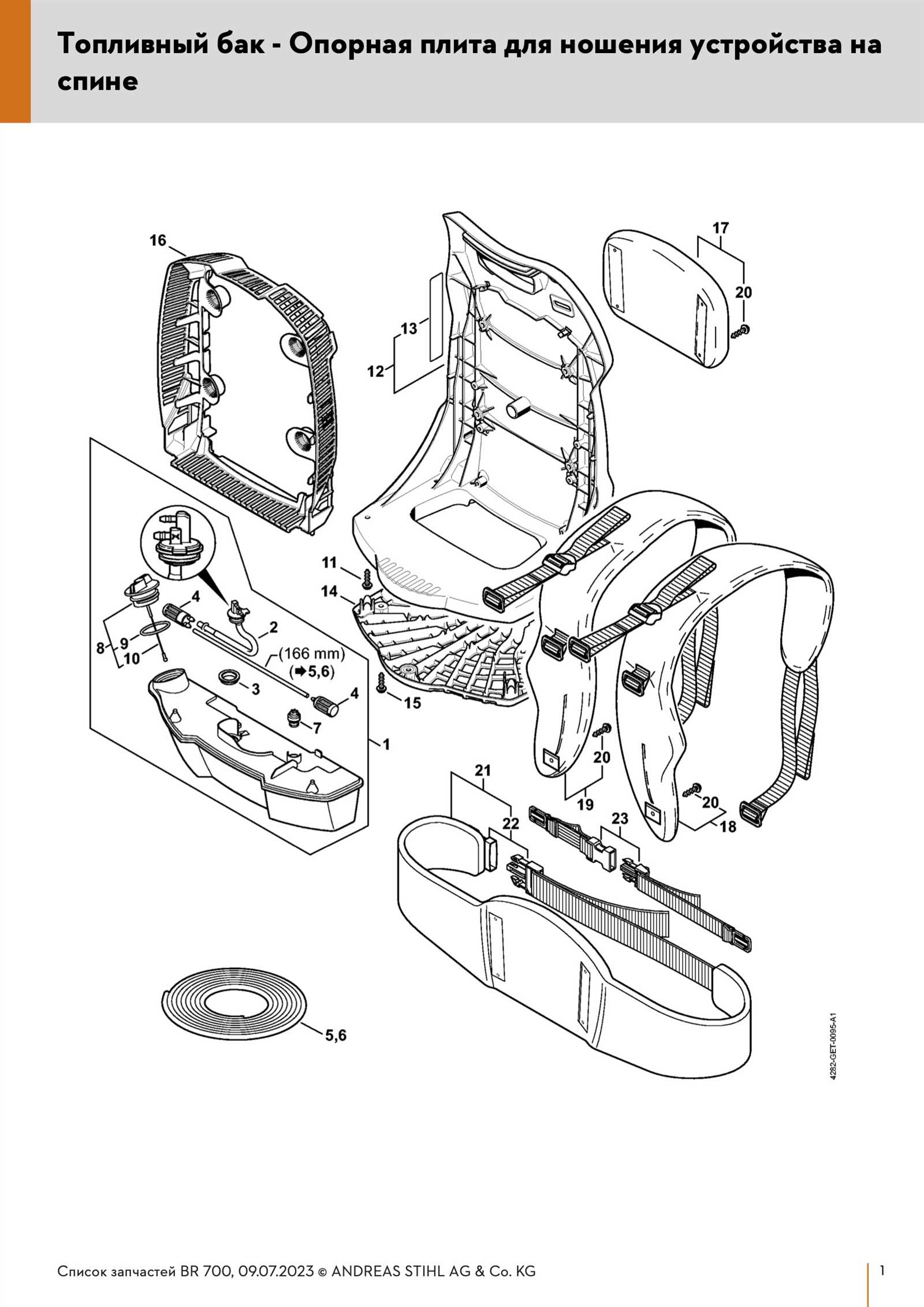

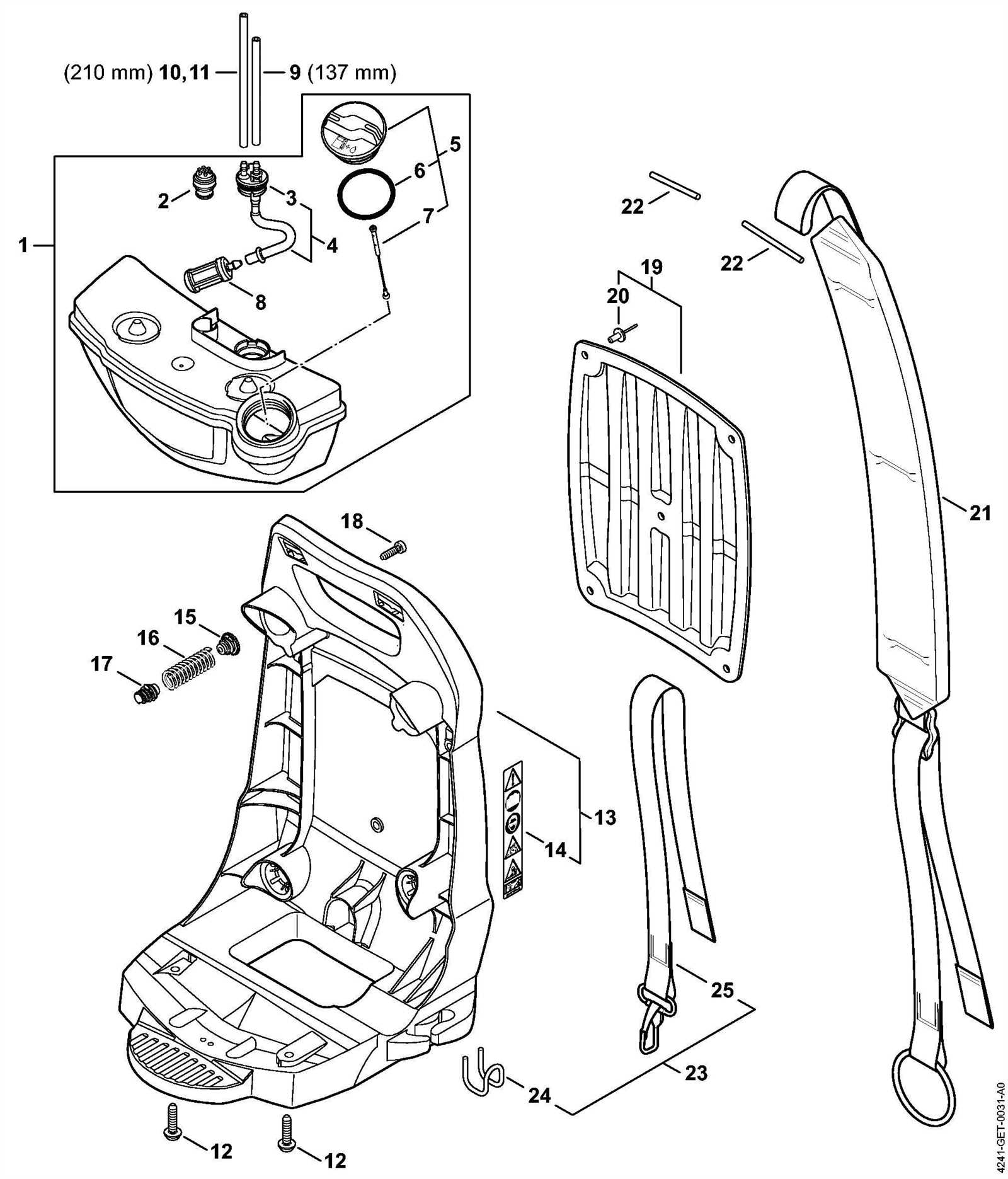

Start by focusing on the overall layout of the tool. Break down the image into smaller sections to understand the major components. Once you’re familiar with these sections, zoom in on each individual piece for a clearer picture of how it interacts with the rest of the tool.

- Identify the Key Elements: Look for labels or numbers that correspond to the components you need. This helps narrow down your search when you need specific details.

- Compare with the Actual Tool: It’s beneficial to cross-reference the image with your equipment to ensure that you’re focusing on the right parts during troubleshooting or repair.

Maximizing Efficiency During Maintenance

Once you’re comfortable with the visual layout, use it as a roadmap for your repairs. If something is malfunctioning, locate the component in the diagram and check its condition. Having a clear reference will save time and reduce the risk of errors during maintenance.

By becoming familiar with this tool, you’ll be able to perform repairs more efficiently and understand the functionality of each component with greater ease.

Common Repairs for Outdoor Power Equipment

Over time, outdoor power tools can experience wear and tear, leading to a variety of issues that require attention. Understanding the most common repairs for these tools is essential for maintaining their performance and longevity. By identifying frequent problems and learning how to address them, you can keep your equipment running smoothly and avoid costly professional repairs.

Fuel System Issues

One of the most common issues with outdoor tools is related to the fuel system. Clogged fuel filters, dirty fuel lines, or a malfunctioning carburetor can lead to poor performance or even complete engine failure. Regularly checking and cleaning these components is essential to ensuring smooth operation.

- Clogged Fuel Filters: Replace any dirty or clogged filters to maintain fuel flow.

- Faulty Fuel Lines: Inspect for cracks or leaks and replace damaged lines to prevent fuel loss.

- Carburetor Problems: Cleaning or rebuilding the carburetor can restore proper fuel mixing and engine performance.

Airflow and Cooling Problems

Proper airflow is crucial for engine cooling and optimal performance. A blocked air filter or malfunctioning exhaust system can lead to overheating, causing significant damage if left unchecked. Regularly inspecting and cleaning the intake and exhaust areas helps prevent overheating and extends the life of the engine.

- Dirty Air Filters: Replace or clean the air filter regularly to maintain proper airflow.

- Exhaust Blockages: Check for any blockages in the exhaust system that could prevent gases from escaping efficiently.

By addressing these common issues and performing regular maintenance, you can keep your outdoor equipment running in top condition for years to come.

Maintenance Tips for Long-Lasting Performance

Regular upkeep of your outdoor tools ensures they remain in optimal condition and operate efficiently. By following simple yet effective maintenance practices, you can extend the life of your equipment and prevent costly repairs. These tasks not only improve performance but also enhance safety and reliability over time.

Regular Cleaning and Inspections

Routine cleaning and inspection are crucial to keeping your equipment functioning at its best. Dirt, debris, and wear can accumulate over time, affecting the efficiency of the tool. Cleaning the machine after each use and performing periodic inspections can prevent minor issues from escalating into major problems.

- Clean the Air Filter: Remove dirt and dust from the air filter to ensure proper airflow and engine cooling.

- Inspect the Fuel System: Check for leaks or blockages in fuel lines and filters to maintain consistent fuel flow.

- Check the Spark Plug: Ensure the spark plug is clean and functioning properly to avoid starting issues.

Proper Storage Practices

How you store your equipment also plays a significant role in its longevity. Storing tools in a clean, dry place prevents rust, corrosion, and deterioration of internal components. Additionally, using the right fuel and properly maintaining the engine when not in use can improve the performance when you need it most.

- Store in a Dry Area: Prevent moisture buildup and rust by keeping your tool in a sheltered environment.

- Use Fresh Fuel: Always use fresh fuel and add fuel stabilizer if storing for an extended period.

By incorporating these simple maintenance steps into your routine, you can ensure your outdoor equipment remains reliable and performs at its peak for years to come.

Identifying Outdoor Tool Components Quickly

Knowing how to identify and locate components in your outdoor equipment can save you time and effort when troubleshooting or replacing parts. With a clear understanding of each element, you can swiftly address any issues and perform repairs efficiently. This section will help you recognize key components and understand their role in the overall system.

The key to quick identification lies in familiarizing yourself with the layout and function of each part. Once you are acquainted with the setup, finding and diagnosing specific problems becomes much easier. Using visual references, like diagrams or guides, can be incredibly helpful in navigating complex assemblies.

Start by focusing on the most commonly replaced or serviced parts. These include the engine components, the fuel system, and the intake/exhaust systems. Recognizing these parts early on will allow you to quickly determine whether they need repair or replacement.