Maintaining and repairing lawn equipment requires a solid understanding of its various components. Whether you’re a seasoned professional or a DIY enthusiast, knowing the structure and functions of each element ensures smooth operation and longevity.

One of the most crucial aspects of managing such equipment is being able to identify all its parts. A comprehensive guide helps you recognize each piece’s role and how it interacts with others to facilitate performance. When issues arise, this knowledge allows for quick troubleshooting and efficient repairs.

Familiarizing yourself with the intricate details of these machines can prevent unnecessary delays and expenses. Whether it’s replacing a malfunctioning element or performing routine maintenance, having access to clear and accurate information is key to keeping everything running smoothly.

Understanding the Parts of a Troy Bilt Mower

Effective operation and repair of lawn care equipment depend heavily on a solid understanding of its components. Each element plays a critical role in the machine’s performance, and knowing how they work together makes it easier to identify issues and perform maintenance tasks efficiently.

Key Components for Smooth Operation

The core elements of such machines include the engine, transmission system, and cutting mechanism. These parts work in harmony to ensure the equipment runs effectively. The engine powers the system, while the transmission allows movement and maneuverability. The cutting mechanism, which includes the blades, ensures the desired finish when working on the lawn.

Maintenance and Troubleshooting

Regular maintenance is essential to prolong the lifespan of any lawn care equipment. Keeping an eye on wear and tear in specific components, like the wheels or belts, can prevent costly repairs. In cases where the equipment doesn’t perform as expected, understanding the layout and function of each piece will help pinpoint the issue quickly.

Knowing your equipment inside and out allows for faster, more accurate diagnostics and ensures that any necessary repairs are handled efficiently. Being familiar with each component’s purpose not only saves time but also contributes to the overall reliability of the machine.

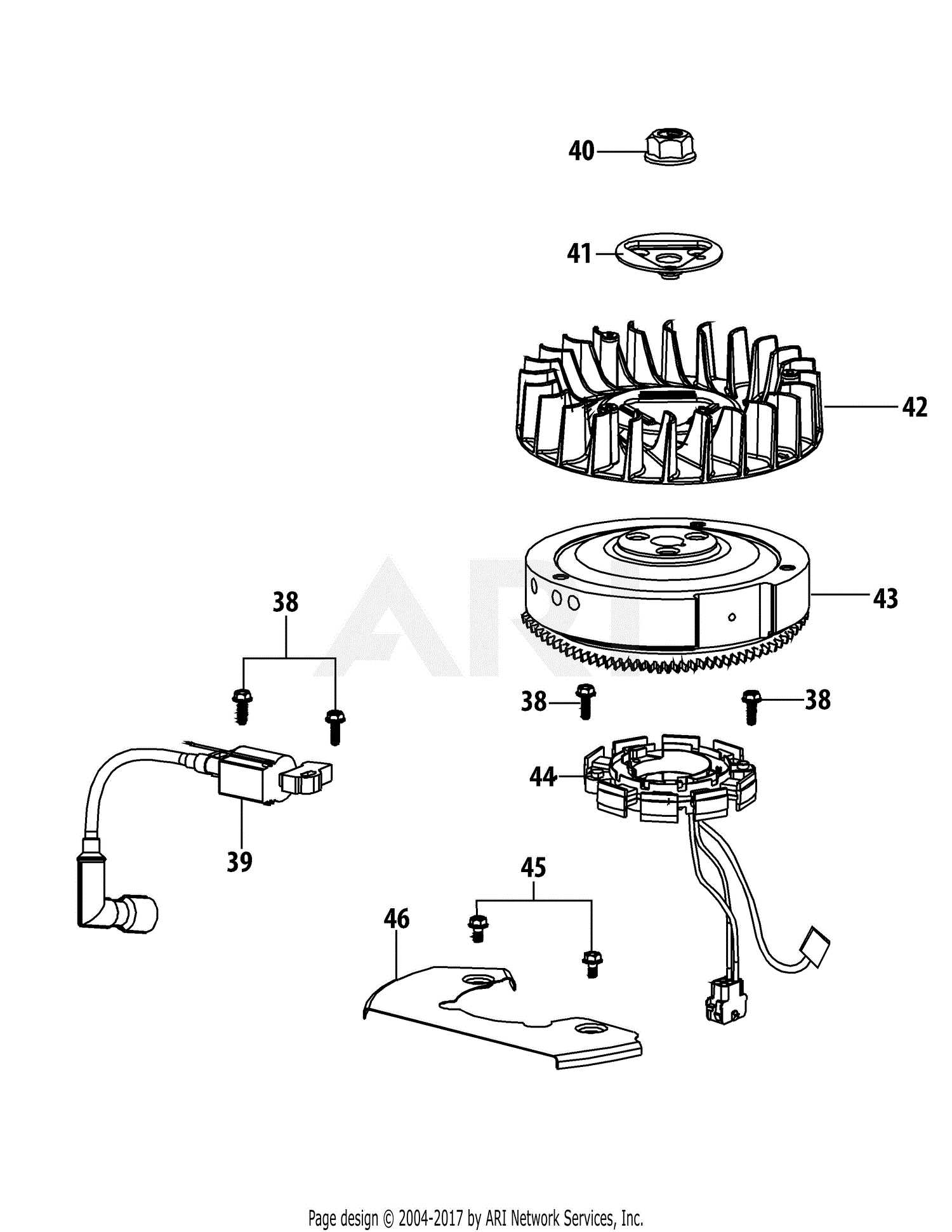

How to Read a Mower Parts Diagram

Understanding a machine’s layout requires interpreting visual representations that show how different elements are connected and function together. These guides are essential when it comes to identifying specific components and their placement within the system. By reading them correctly, users can easily locate, repair, or replace faulty parts.

Identifying Key Components

The first step in reading such guides is recognizing the main sections and labels. Each part is typically numbered or marked, providing an easy way to find corresponding descriptions in a separate list. These diagrams often include arrows, lines, and other symbols to show how various components interact with each other.

Interpreting Connections and Functions

Once the components are identified, it’s important to understand how they work together. Look for lines or arrows that indicate connections, such as power transfer or control systems. Understanding the flow of energy and movement will help you troubleshoot problems or assemble parts correctly after maintenance or replacement.

Being able to read and interpret these diagrams is crucial for anyone working with lawn equipment. It ensures that repairs are done accurately and helps in ordering the correct replacement parts when necessary.

Essential Components for Maintenance and Repair

Proper upkeep of lawn equipment relies heavily on understanding and maintaining its core components. Each part plays a specific role in ensuring the smooth operation of the system. Recognizing which components require regular attention can prevent unexpected breakdowns and extend the lifespan of the machine.

Key elements that demand attention include the engine, transmission system, and cutting mechanism. The engine requires regular oil changes and air filter replacements to maintain performance. The transmission system, which controls movement, should be checked for wear in belts and gears. The cutting mechanism, especially the blades, needs sharpening or replacing when damaged to ensure optimal functionality.

Focusing on these primary components during maintenance can save time and reduce repair costs. Regular checks and immediate attention to worn parts will ensure your equipment continues to function effectively throughout its life.