Every outboard motor is composed of numerous components that work together to ensure smooth performance on the water. A clear understanding of these elements and their arrangement is essential for proper maintenance, troubleshooting, and repair. By familiarizing yourself with the layout of each piece, you can efficiently identify any issues that may arise.

Knowing the internal workings of your engine helps in diagnosing problems quickly. With a well-organized map of the motor, you can easily locate vital parts such as the fuel system, ignition, and cooling components. This knowledge will also assist in replacing damaged parts or upgrading the engine for enhanced performance.

Utilizing a detailed visual reference can significantly streamline the repair process. This guide will help you navigate through the essential elements of the outboard engine, empowering you to perform maintenance tasks confidently and accurately.

Understanding the Outboard Motor Layout

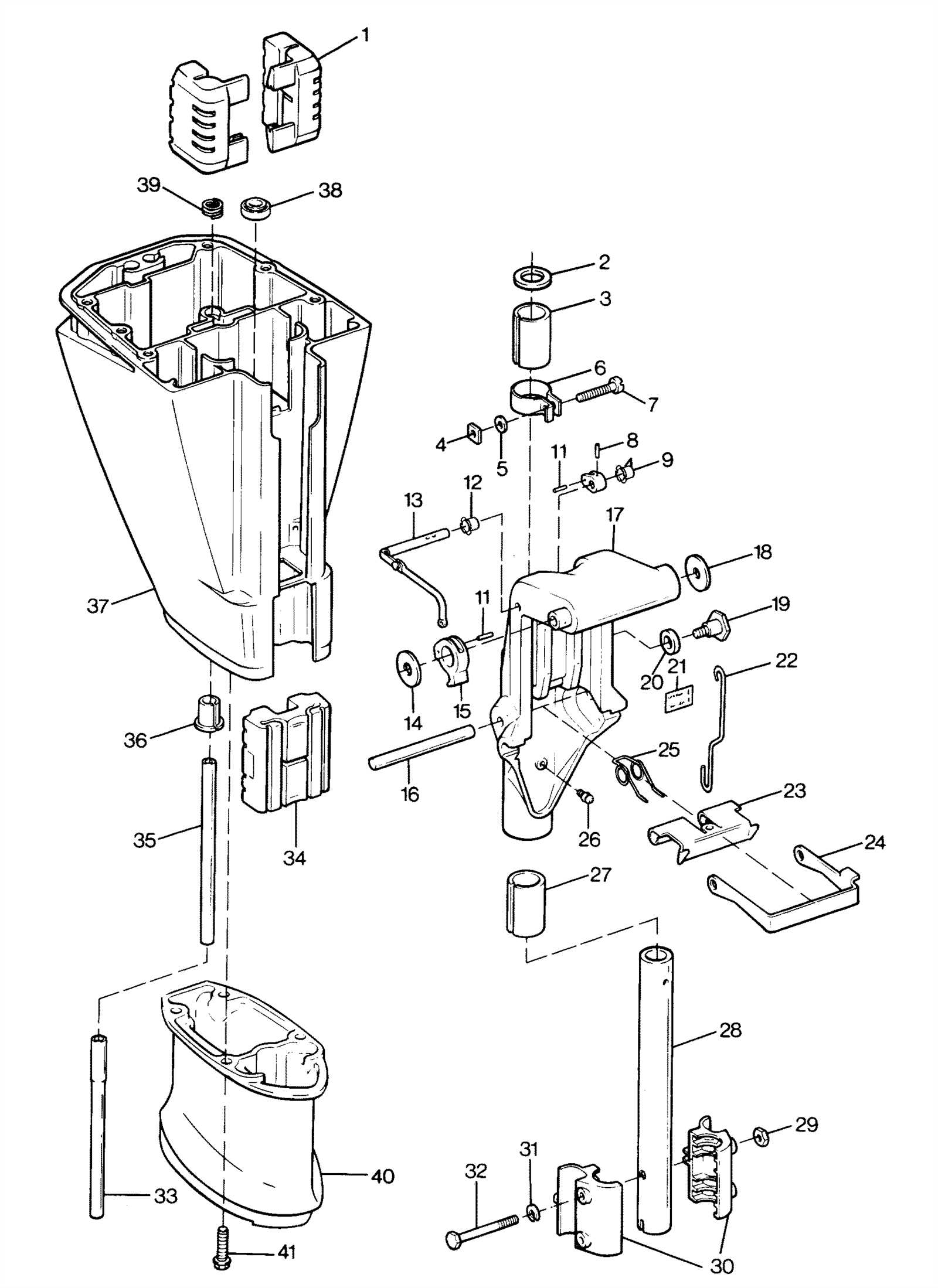

When working with any engine, it’s important to understand how each component fits together and functions. In the case of an outboard engine, this knowledge allows you to efficiently troubleshoot, repair, or maintain the motor. A well-organized layout provides a clear view of all the necessary components, from the powerhead to the lower unit, making it easier to identify any areas that need attention.

By studying the engine’s design, you can get a better understanding of how various elements, such as the fuel system, ignition, and cooling mechanisms, interact. This helps ensure the longevity and optimal performance of the engine. Knowing where each part is located and how it contributes to the overall system is key to keeping everything running smoothly.

With a visual representation, you can also pinpoint any faulty or worn-out parts more effectively. This reduces the risk of overlooking essential components and minimizes the chances of delays during maintenance or repairs. Understanding the overall layout of your engine is an essential skill for any technician or boat owner.

Key Components in the Outboard Motor

Every outboard engine consists of several critical elements that work together to ensure reliable operation. These components are designed to function in harmony, each playing a vital role in the overall performance of the motor. Understanding the key elements will help you better maintain and troubleshoot the engine, ensuring that it operates at its best.

Powerhead and Ignition System

The powerhead is the heart of the engine, housing essential components such as the crankshaft, pistons, and cylinders. It is responsible for generating the power needed to drive the motor. The ignition system works closely with the powerhead, providing the spark that ignites the fuel mixture. Regular maintenance of both parts is crucial for reliable engine performance.

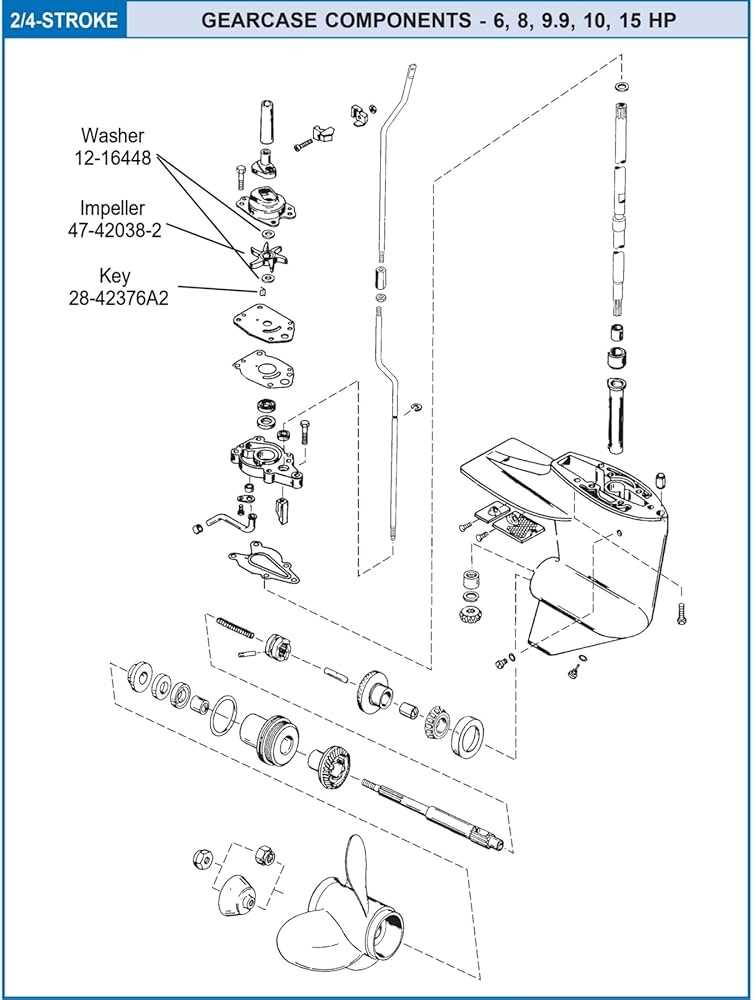

Lower Unit and Propeller Assembly

The lower unit connects the motor to the water, containing the gearbox and propeller shaft. This section transmits power from the engine to the propeller, allowing the boat to move. The propeller assembly plays a key role in controlling the speed and direction of the vessel. Keeping the lower unit and propeller in good condition ensures efficient movement through the water.

How to Use the Engine Component Layout

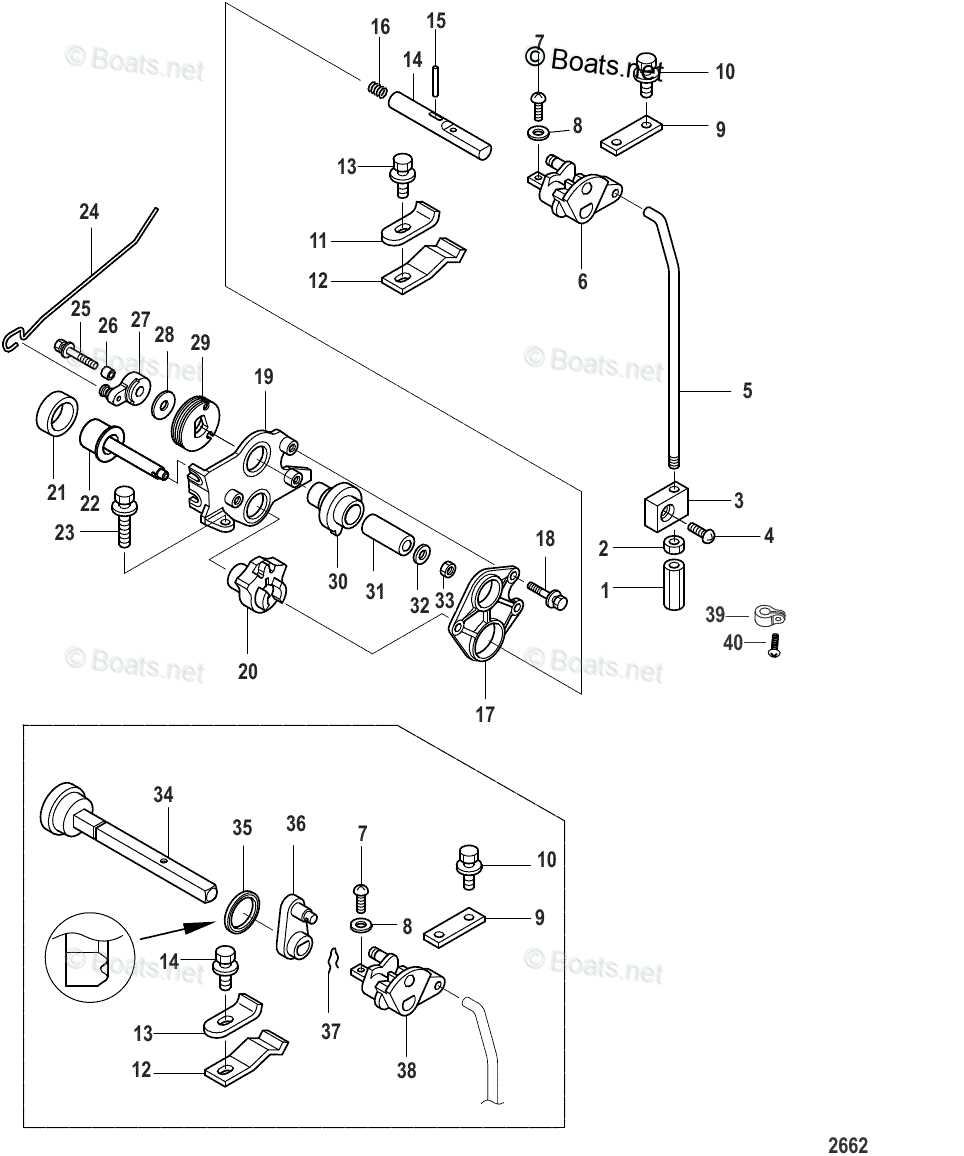

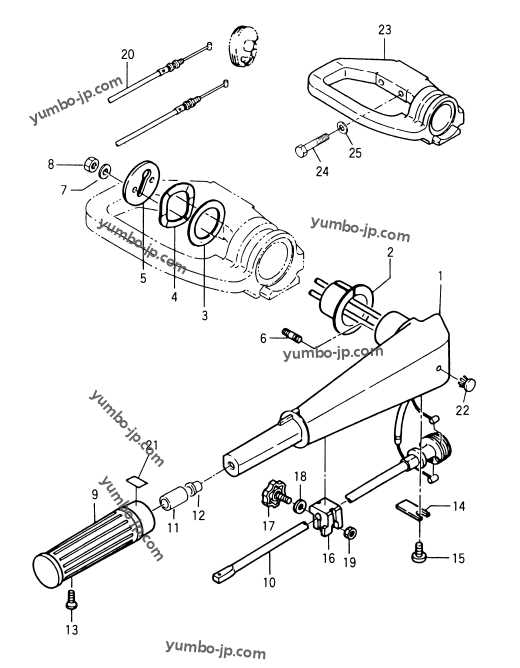

Understanding how to read an engine layout is essential for effective maintenance and repair. A detailed layout provides a visual representation of all the critical parts, helping you identify each component and its role. Knowing how to use this visual guide ensures you can quickly locate the necessary parts when performing troubleshooting or replacements.

Start by familiarizing yourself with the key sections of the engine, such as the power unit, fuel system, and drive assembly. Each part is labeled, making it easier to match the physical components with the layout. Once you are comfortable with the organization, use the diagram to pinpoint any areas of concern and cross-reference with your maintenance tasks.

Having a clear understanding of the layout enables more efficient repairs. When a specific part needs attention, you can quickly identify its location and check for wear or damage. This approach reduces the time spent searching for parts and improves the accuracy of your repairs.