When maintaining or repairing outdoor equipment, understanding its structure and individual elements is essential. Knowing how each piece fits together ensures efficient operation and can help identify issues faster. This knowledge also simplifies the process of ordering replacements and assembling the machine correctly.

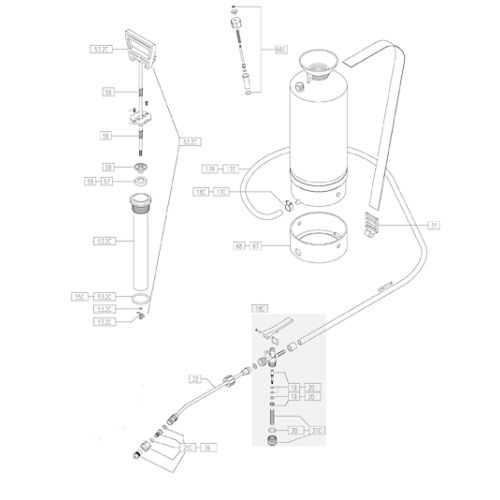

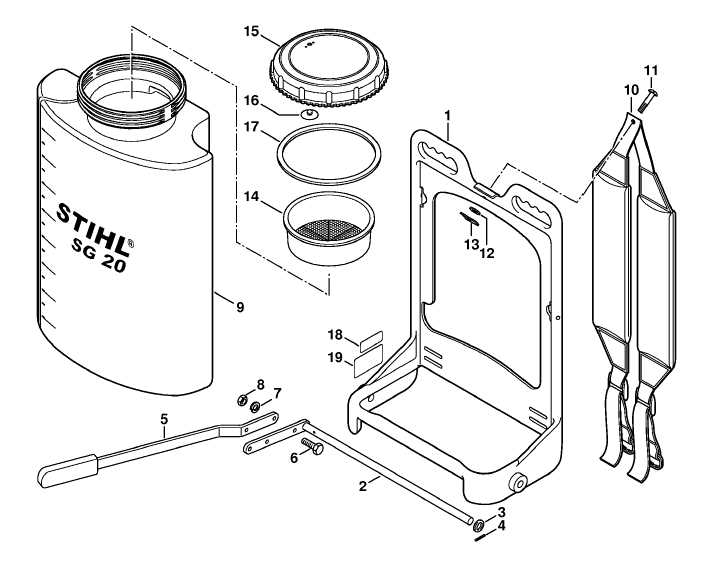

Detailed illustrations can be invaluable in recognizing specific parts and their connections. These visual aids serve as a reference for technicians and users alike, offering clarity when dealing with complex machinery.

Whether you are troubleshooting or performing routine maintenance, a thorough understanding of your equipment’s layout will save time and effort. A clear visual representation makes it easier to pinpoint faults and replace worn-out components.

Understanding Equipment Layout

Properly understanding the layout of any machinery is crucial for both efficient operation and troubleshooting. By having a clear view of how components are arranged, users can quickly identify issues and ensure everything is in its correct position. A well-organized design allows for a smooth workflow and reduces the likelihood of errors during assembly or maintenance.

Clear visual guides offer great value in helping users familiarize themselves with the arrangement of each element. These guides can show the relationship between different parts and how they interact within the overall structure, ensuring that repairs or replacements are done with accuracy.

Familiarity with the layout also provides significant benefits during routine checks. By knowing where each component is located, users can spot any signs of wear or damage early, preventing more serious problems down the line.

Identifying Key Components of Model

Understanding the main elements of a machine is essential for effective maintenance and troubleshooting. Each key component plays a specific role in ensuring smooth operation, and being able to identify them quickly can save time and effort. Recognizing these parts allows for easier detection of faults and the ability to address them promptly.

Essential Mechanical Elements

Critical mechanical components, such as the engine, fuel system, and drive mechanisms, form the backbone of any machine. These parts interact to ensure proper functioning, and their alignment and condition must be regularly checked. A malfunction in one of these areas can lead to poor performance or even complete failure of the equipment.

Supporting Parts and Accessories

Beyond the primary mechanisms, various smaller accessories and attachments are also integral to the machine’s operation. These elements often include handles, levers, and safety features. Identifying and maintaining these supporting components is just as important to ensure safety and usability.

How to Use the Equipment Layout Guide

Using a detailed layout guide effectively can significantly streamline both maintenance and repair processes. These guides provide a clear representation of how the components of a machine are arranged, allowing users to easily identify where each part fits within the larger system. Knowing how to read these guides ensures faster diagnosis of issues and simplifies the task of finding the correct replacement parts.

To begin, study the layout thoroughly to understand the positioning of each critical component. Focus on the key areas first, such as the power system, operational controls, and safety features. This will give you a solid foundation for troubleshooting and help you navigate the guide with confidence.

Next, use the visual references to cross-check specific parts that need replacement or inspection. The clarity of these visual aids can help you pinpoint problem areas quickly and verify if the parts you have match those shown in the guide. This minimizes errors during the maintenance or assembly process and ensures that you are working with the correct components.