Maintaining and repairing your boat’s motor is essential for its longevity and optimal performance. Understanding the various components of the system is the first step toward successful upkeep. In this section, we’ll explore the critical parts and their functions to help you identify, troubleshoot, and replace components when necessary.

From the electrical elements to mechanical components, every part plays a significant role in the motor’s efficiency. By familiarizing yourself with these elements, you can ensure that each part is functioning correctly, reducing the chances of unexpected breakdowns and ensuring smooth operation during your time on the water.

Knowing the system inside and out empowers you to address minor issues before they escalate. With proper maintenance, your motor will perform at its best, extending its lifespan and giving you peace of mind while you’re out on the water.

Understanding Motor Components

Knowing the key elements of your motor system is crucial for proper maintenance and effective troubleshooting. Every component serves a unique function that contributes to the smooth operation of your device. Understanding how each piece interacts within the system can help you address issues promptly and keep everything running efficiently.

Each element, from electrical connectors to mechanical gears, works in unison to provide optimal performance. By identifying the role of each part, you can more easily determine the cause of any problems and take appropriate action. This knowledge ensures that maintenance tasks, whether they are simple repairs or routine checks, are done with precision and care.

With a clear understanding of your motor’s structure, you can significantly reduce downtime, extend its lifespan, and improve your overall boating experience. Whether you’re replacing a worn-out component or enhancing the system’s functionality, being familiar with its inner workings is essential for any boat owner.

How to Identify Motor Components

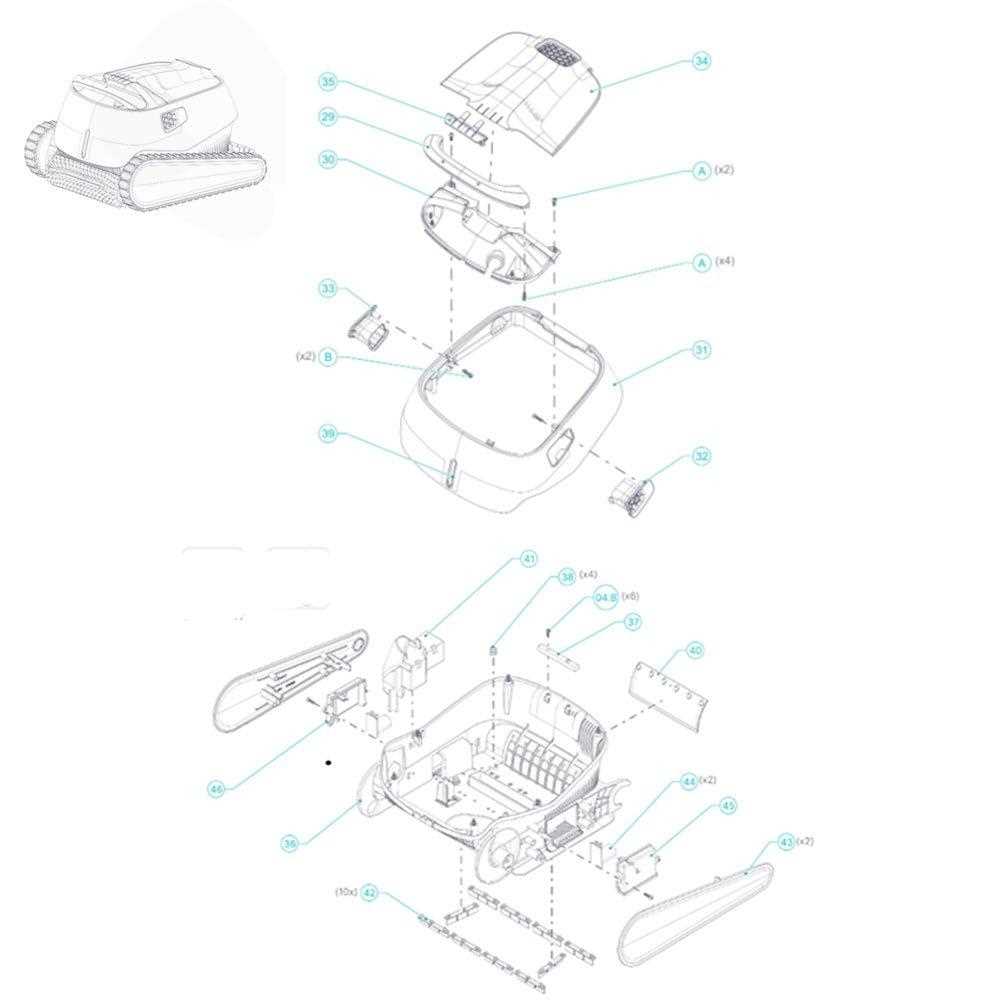

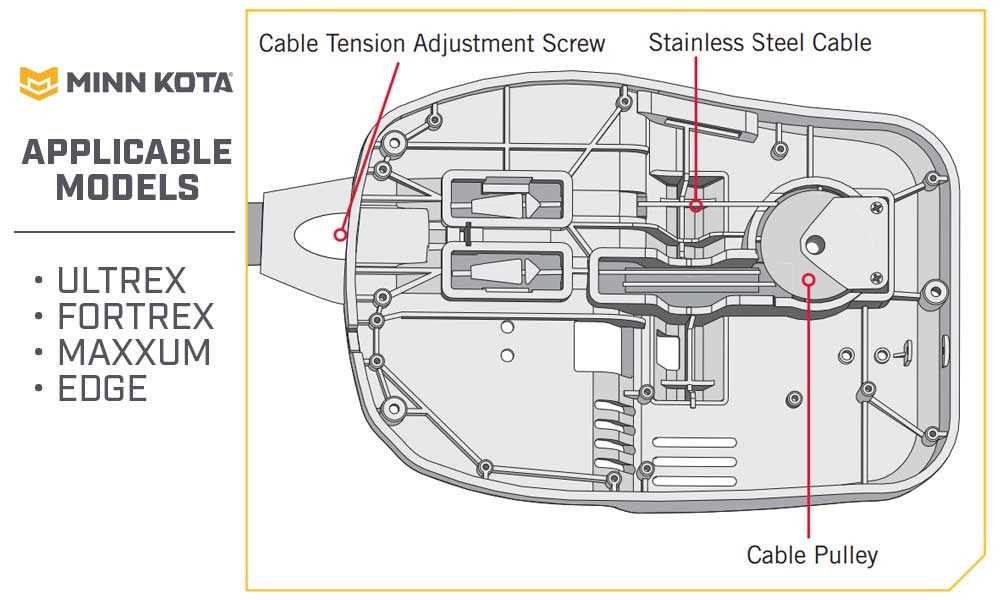

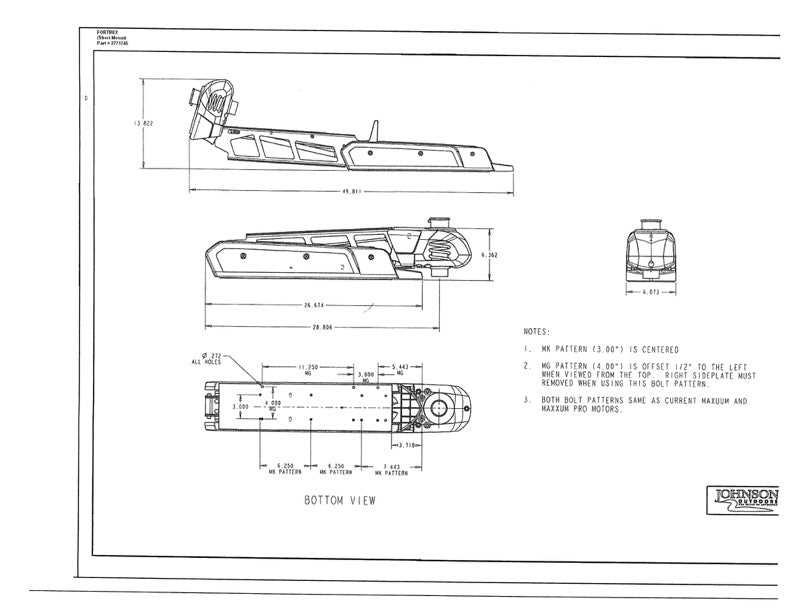

Identifying the individual elements of your motor system is essential for proper maintenance and repairs. Understanding the distinct characteristics of each part will allow you to assess its condition and determine whether it needs replacement or attention. A keen eye for detail can make all the difference when troubleshooting and enhancing motor performance.

Visual Inspection

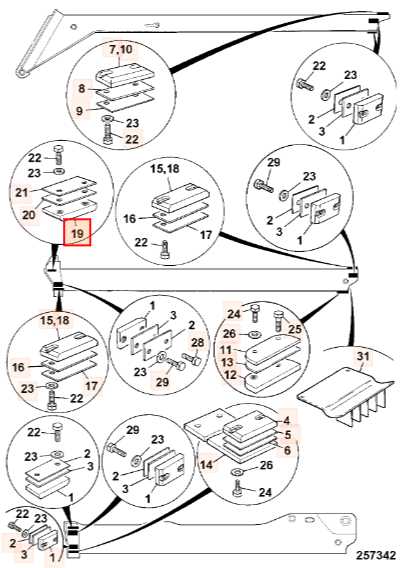

Start by carefully examining each component for visible signs of wear, damage, or corrosion. Pay attention to the shape, size, and positioning of the components. Corroded wiring, loose fasteners, or cracked seals can indicate areas that require immediate attention. Clear labels or numbering on the parts can also guide you in pinpointing their identity.

Consulting the Manual

Your motor’s manual is an invaluable resource for identifying components. It provides detailed descriptions and diagrams, which help you recognize each piece and understand its function within the system. Cross-referencing the manual with your visual inspection ensures accurate identification, which simplifies any repair or maintenance procedures.

Repair and Maintenance Tips for Motor Systems

Proper maintenance and timely repairs are essential for extending the lifespan and ensuring the smooth operation of your motor system. Regular upkeep prevents small issues from becoming major problems and enhances the overall performance of your equipment. Whether you are dealing with a malfunctioning part or simply performing routine checks, these tips will help keep everything in top condition.

Routine Cleaning and Inspection

One of the simplest yet most effective maintenance tasks is regular cleaning. Over time, dirt, debris, and saltwater can accumulate on various components, causing corrosion or wear. Clean the motor’s exterior, as well as the internal parts, and inspect for any signs of damage or wear. Make sure the electrical connections are free from moisture, and lubricate any moving parts as needed to prevent friction and damage.

Replacing Worn or Damaged Parts

Addressing any worn-out or damaged components promptly can save you from costly repairs down the road. Regularly check for cracks, frayed wires, or any loose connections that may affect performance. Replacing damaged elements ensures the continued reliability of the motor and avoids unexpected failures during use. Always use high-quality replacement parts to maintain the integrity of the system.