Understanding the layout of engine components is crucial for maintaining and troubleshooting small motors. Whether you’re a professional mechanic or a DIY enthusiast, having a clear view of how each part fits together can save time and effort during repairs or upgrades. This guide focuses on providing a visual representation of essential engine elements to help you better comprehend their function and placement.

Accurate identification of engine components can enhance your ability to perform maintenance tasks efficiently. From identifying wear and tear to finding suitable replacements, knowing the exact structure and placement of each piece will make troubleshooting a more straightforward process. This knowledge is vital for ensuring long-lasting performance and avoiding costly repairs.

Visual guides offer a reliable reference for assembling or disassembling an engine, especially when dealing with complex or intricate systems. Understanding the configuration of parts ensures that maintenance is carried out effectively, reducing the risk of errors that could impact the engine’s performance.

Understanding the Kohler CV16S Engine

To maintain optimal engine performance, it’s essential to understand its fundamental components and how they interact. Whether you’re performing routine maintenance or troubleshooting, having a solid grasp of the system’s key elements is vital for ensuring smooth operation and longevity.

The engine in question is a robust and reliable small engine designed for a variety of applications. It combines durability with performance, making it a popular choice for equipment that requires consistent power output. Understanding how the engine is assembled and how its key parts work together will help in diagnosing issues and performing effective maintenance.

- Power output: The engine is designed to deliver consistent power, crucial for tasks requiring constant operation.

- Cooling system: A proper cooling mechanism is in place to maintain efficient temperature control during operation, preventing overheating.

- Fuel delivery: Efficient fuel management ensures optimal combustion, improving overall efficiency and engine lifespan.

Recognizing how each component functions together will make it easier to identify potential issues and ensure your engine is running at its best. Additionally, understanding these parts helps in selecting the right replacements and ensuring the engine’s components are compatible with each other. Whether performing minor repairs or major overhauls, knowledge of the internal workings of the engine is crucial for success.

Key Components of the CV16S Diagram

To fully comprehend how an engine operates, it’s essential to understand its critical components and their roles within the system. These elements work in tandem to ensure efficient power generation, smooth operation, and longevity. Identifying and maintaining these core parts is key to optimizing performance and preventing potential malfunctions.

Power and Ignition System

The power and ignition system is responsible for starting the engine and ensuring it continues to run smoothly. It includes the spark plug, ignition coil, and flywheel, all of which play an integral part in generating the electrical spark that ignites the fuel mixture. A well-maintained ignition system ensures reliable starting and consistent engine performance.

Fuel and Lubrication Systems

The fuel system delivers the necessary fuel to the engine, while the lubrication system ensures that moving components remain well-oiled, reducing friction and wear. These systems are essential for maintaining engine efficiency and preventing overheating. Key components like the carburetor, fuel pump, oil filter, and oil pump must be checked regularly to ensure that both systems operate effectively.

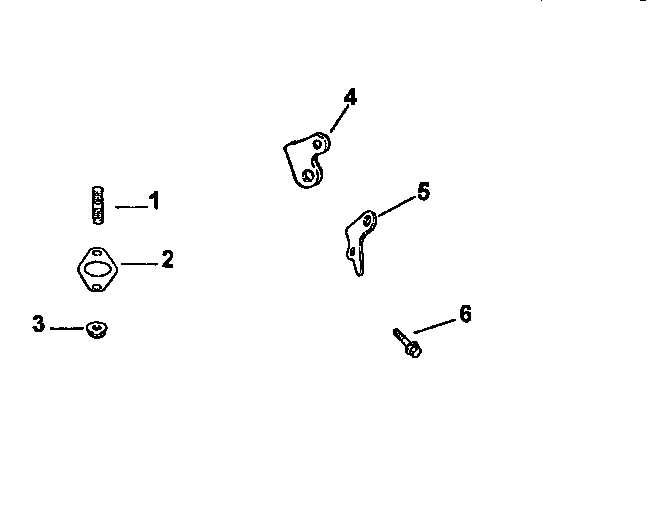

How to Interpret the Parts Diagram

Understanding an engine’s layout requires recognizing how each component is represented visually. A clear illustration of the components helps identify where each part fits into the overall system. Knowing how to read these visual guides makes it easier to troubleshoot issues and perform repairs or replacements accurately.

Identifying Components and Labels

The first step in interpreting any visual guide is to identify the labeled components. Each part is usually marked with a number or name, corresponding to a list that provides detailed descriptions or specifications. This makes it easier to find and replace specific elements without confusion.

Using the Diagram for Maintenance and Repairs

Once the components are identified, the diagram serves as a roadmap for both maintenance and repairs. Whether you’re looking to replace a worn part or simply inspect the system, understanding the layout ensures that each part is correctly positioned and functioning properly.

| Component | Description | Function |

|---|---|---|

| Fuel Pump | Delivers fuel to the engine | Ensures proper fuel flow for combustion |

| Oil Filter | Filters contaminants from the engine oil | Prevents damage to engine components by maintaining clean oil |

| Ignition Coil | Generates electrical energy for spark plug | Starts the engine by igniting the air-fuel mixture |

Common Issues and Maintenance Tips

Every engine, regardless of its design, can experience common issues over time. Understanding these problems and knowing how to address them is essential for maintaining reliable performance. Regular maintenance ensures the longevity of the system and helps prevent major failures before they happen.

Engine Not Starting

One of the most common issues faced by engine owners is difficulty starting the machine. This could be caused by a number of factors, including a faulty ignition system, clogged fuel lines, or a drained battery. To prevent this issue, it’s important to check the ignition coil, spark plug, and fuel system periodically. Cleaning the carburetor and ensuring the battery is fully charged can make a big difference.

Overheating and Reduced Power

Overheating can occur if the cooling system is not functioning properly or if there is a lack of lubrication. If the engine begins to lose power or emits excessive heat, it’s crucial to check the oil levels and ensure the cooling fan is clear of debris. Additionally, regular oil changes are key to maintaining the engine’s temperature. Replacing air filters and ensuring proper airflow can also help avoid overheating.

Upgrading and Replacing Engine Components

Over time, some engine components may wear out or become less efficient, requiring replacement or upgrading to maintain peak performance. Replacing worn-out parts or opting for upgrades can enhance the overall functionality of the machine. Understanding which parts to replace and how to improve certain features will help ensure smooth and reliable operation.

When to Replace Key Components

It’s important to monitor key components for signs of wear, such as excessive noise, poor performance, or visible damage. Common components that often need replacing include the spark plug, fuel filter, and air filter. These parts should be inspected regularly and replaced as needed to maintain optimal engine performance. Timely replacement can prevent further damage and increase the engine’s lifespan.

Upgrading for Enhanced Performance

Upgrading specific components can improve engine efficiency and power output. For example, replacing the carburetor with a more advanced model or installing a high-performance air filter can help increase airflow and fuel combustion. Investing in premium-quality spark plugs can also lead to smoother ignition and better fuel efficiency. Upgrades like these can provide noticeable improvements in performance, especially in heavy-duty applications.