Proper maintenance and understanding of your outdoor machinery are essential for keeping it running smoothly. Identifying the different elements that make up the device can help you troubleshoot issues more effectively. Familiarizing yourself with how each part functions allows you to address any malfunctions and extend the lifespan of your equipment.

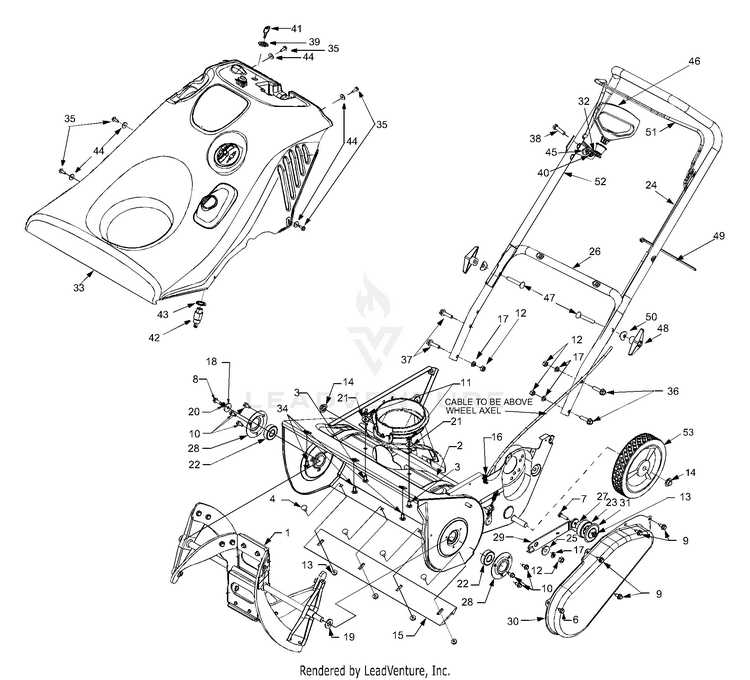

When working with mechanical tools designed for winter tasks, knowing the layout and roles of individual components is crucial. These machines consist of various essential elements that work together to deliver optimal performance. Understanding where each component fits and how it operates can be the key to successful repairs or replacements when needed.

For those looking to enhance their maintenance skills, visualizing how the parts come together can offer clear insights into the machine’s structure. This knowledge enables quicker problem-solving and ensures you are well-prepared for any necessary upkeep. A clear understanding also helps you make informed decisions when ordering replacements or looking for specific parts.

Understanding Snow Removal Equipment Components

Every outdoor machine designed for clearing snow is made up of several essential elements that work together to provide optimal performance. Familiarizing yourself with these components will help ensure smoother operation, efficient troubleshooting, and better maintenance. Whether you’re dealing with minor repairs or routine checks, knowing the role of each part is crucial for achieving long-lasting results.

Key Functional Elements

At the core of any snow clearing equipment, you’ll find mechanisms like the engine, auger, and chute system. These core components are responsible for powering the unit, collecting the snow, and directing it to the desired location. Understanding how they interact can aid in recognizing early signs of wear or malfunction.

Maintenance and Replacement Considerations

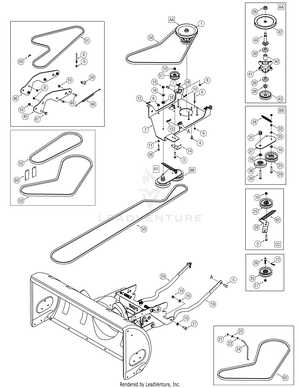

Proper care of each individual component is necessary to avoid expensive repairs or a breakdown during crucial times. Regularly inspecting the engine, belt systems, and control mechanisms can help prevent common issues. When parts become damaged or worn out, knowing how to identify and replace them ensures minimal downtime.

Key Parts for Efficient Snow Removal

For optimal snow clearing performance, it’s essential to understand the key elements that make up your outdoor machine. These components are designed to work in harmony, ensuring efficient operation and preventing unnecessary wear. Knowing which parts are crucial for snow removal will help you keep the equipment in peak condition and ready for use when needed.

Power and Drive Mechanisms

The engine and drive systems are the heart of the equipment, providing the necessary power to clear snow effectively. The engine drives the auger and wheels, allowing the machine to collect and throw snow. Regular maintenance of these components ensures smooth operation, avoiding sluggish performance or sudden failures.

Snow Collection and Displacement Systems

Components such as the auger and chute are vital for efficiently gathering and directing the snow. The auger breaks down the snow and moves it toward the chute, which then ejects the snow at a specific angle. Ensuring these systems are free from blockages and properly aligned will significantly improve the machine’s efficiency.

How to Identify Equipment Part Issues

Recognizing when something is wrong with your outdoor machinery is the first step in addressing potential problems. By observing the machine’s performance and conducting regular checks, you can pinpoint issues before they become serious. Identifying specific malfunctions early can save both time and money on repairs.

Common signs of trouble include unusual sounds, reduced power, or irregular movement. For instance, if the engine is running but the auger isn’t rotating properly, it could indicate a mechanical failure or a problem with the drive system. Likewise, poor snow discharge can suggest a clog or misalignment in the chute.

Thoroughly inspecting each key component–such as the engine, belts, and chute–can help you detect wear, misalignment, or damage. By following a step-by-step diagnostic approach, you’ll be able to pinpoint issues with greater accuracy, making repairs or replacements easier to manage.