The inner workings of complex machinery are often more intricate than they appear on the surface. To comprehend how these systems function, it is crucial to break down their various components and understand their roles in the overall operation. A well-organized overview of each element allows us to grasp how they interact and contribute to the seamless performance of the device.

Various sections play unique roles, each contributing to the system’s efficiency. From the core that generates movement to the supporting structures that enable smooth operation, understanding these elements provides insight into how everything works in harmony. It’s through this interconnectedness that power is transmitted, and motion is achieved.

By studying the relationship between these sections, one can better appreciate the complexity of mechanical devices. Knowing how they function together helps both engineers and users troubleshoot, maintain, and optimize the performance of such systems.

Understanding the Structure of Electric Motors

The structure of a complex machine is built upon several interrelated components that work in sync to generate desired output. By examining the fundamental elements that make up these systems, we can gain a deeper understanding of how motion is achieved. Each section plays a specific role in converting energy into mechanical work, and together, they form a unified mechanism that operates efficiently.

The Core Elements of the System

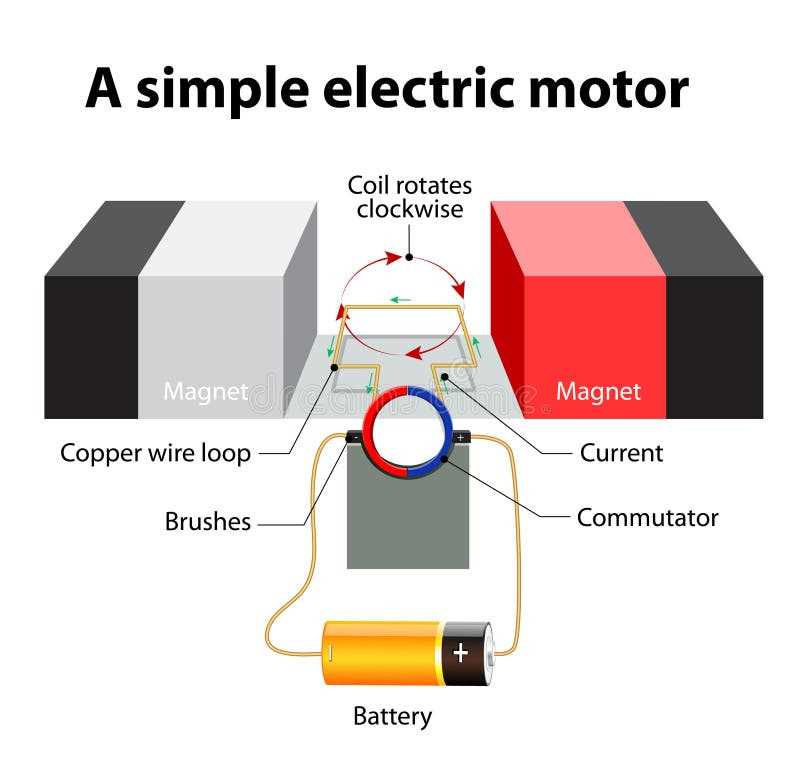

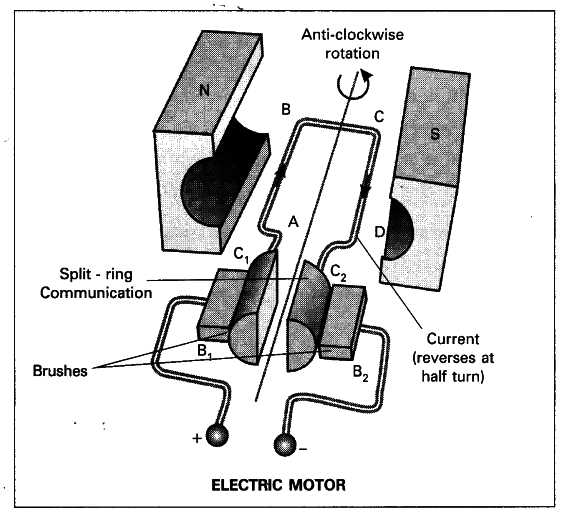

At the heart of any such device lies a set of core components, each crucial for its operation. These elements include a central mechanism that initiates movement, along with supporting structures that guide the flow of energy. The interaction between these components determines the overall functionality and effectiveness of the machine, as it converts electrical energy into kinetic force.

How the Components Work Together

When examining how each element contributes to the system, it becomes clear that their cooperation is essential. The alignment of these sections ensures that energy is transmitted effectively throughout the entire device. If even one component fails to function properly, the entire system can experience a loss in performance or even malfunction. Understanding these relationships is key to maintaining and optimizing the system.

Key Components in an Electric Motor Diagram

The functioning of any mechanical system relies heavily on the individual elements that make up its structure. These components are not only essential for the movement and conversion of energy but also play specific roles that contribute to the overall efficiency and longevity of the device. Understanding each of these key sections and how they interact is critical for both operation and maintenance.

The Central Energy Conversion Unit

One of the primary sections in the system is responsible for the conversion of electrical energy into motion. This central unit is where energy is transformed into mechanical power that drives the entire system. The efficiency of this component directly influences the performance of the device, and its design is crucial for ensuring optimal energy transfer.

Supportive Elements for Stability and Movement

Equally important are the supporting sections that ensure smooth operation. These include structural components that stabilize the system, guide the flow of energy, and maintain the balance of the moving parts. Together, they allow for consistent and reliable motion, ensuring that the device performs its function without interruptions or excess wear.

How Electric Motor Parts Work Together

For any machine to operate effectively, its internal sections must function in harmony. Each component has a specific role, but their true power lies in their ability to work together seamlessly. When all elements are aligned and cooperating, the device can perform its intended task with maximum efficiency.

The process starts when energy is introduced to the system. This energy is then transferred and manipulated by various components that play key roles in its transformation. Below are the main processes that highlight how the sections interact:

- Energy Conversion: The initial step involves converting electrical energy into mechanical motion. This transformation is essential for the entire system to operate.

- Energy Distribution: Once converted, energy is distributed throughout the system by various connectors, ensuring that each component receives the power it needs to function.

- Guiding Movement: The supporting sections guide and stabilize the moving parts, allowing them to rotate smoothly and efficiently without obstruction.

- Feedback Mechanism: As the components work, feedback is continually sent to adjust the system’s performance, ensuring stability and preventing malfunction.

These processes illustrate the coordinated effort required for smooth operation. Without each section performing its task, the entire system could fail to deliver optimal performance.