When dealing with outdoor machinery, understanding its structure is essential for proper operation and maintenance. Every tool is made up of multiple elements, each playing a vital role in its efficiency and functionality. By familiarizing yourself with these components, you ensure better performance and longer lifespan for the equipment.

Having a clear view of the assembly and how different parts interact can help troubleshoot issues, identify wear and tear, and improve the overall maintenance process. A comprehensive guide to these mechanical elements allows users to confidently handle their machines and perform necessary repairs when needed.

Knowledge of each part’s function can significantly impact the ease of use and repair tasks. From the key elements that power the machinery to the smaller, intricate components, a clear understanding makes all the difference in maintaining optimal performance over time.

Understanding Lawn Equipment Components

Every outdoor tool consists of various interconnected elements that work together to ensure smooth functionality. Recognizing how these components interact allows operators to maintain the machinery effectively, troubleshoot issues, and extend its lifespan. Each piece, whether large or small, plays a crucial role in the overall performance and efficiency of the machine.

Main Mechanical Elements

The core components of any equipment are responsible for the primary function. These are the parts that drive the machinery, such as the engine, transmission, and drive systems. Understanding their roles helps users assess the condition of these parts and decide when to perform maintenance or replace them.

Smaller but Crucial Components

In addition to the larger mechanical parts, smaller elements such as belts, pulleys, and blades also contribute significantly to the tool’s effectiveness. Although these components may seem less important, their regular upkeep is essential for smooth operation and optimal results. Failure to maintain these smaller pieces can lead to operational issues and costly repairs.

Regular inspection of both major and minor components ensures that the equipment functions properly, preventing downtime and costly repairs in the future. A deep understanding of these elements fosters confidence and competence in handling and caring for your machine.

How to Read the Equipment Assembly Guide

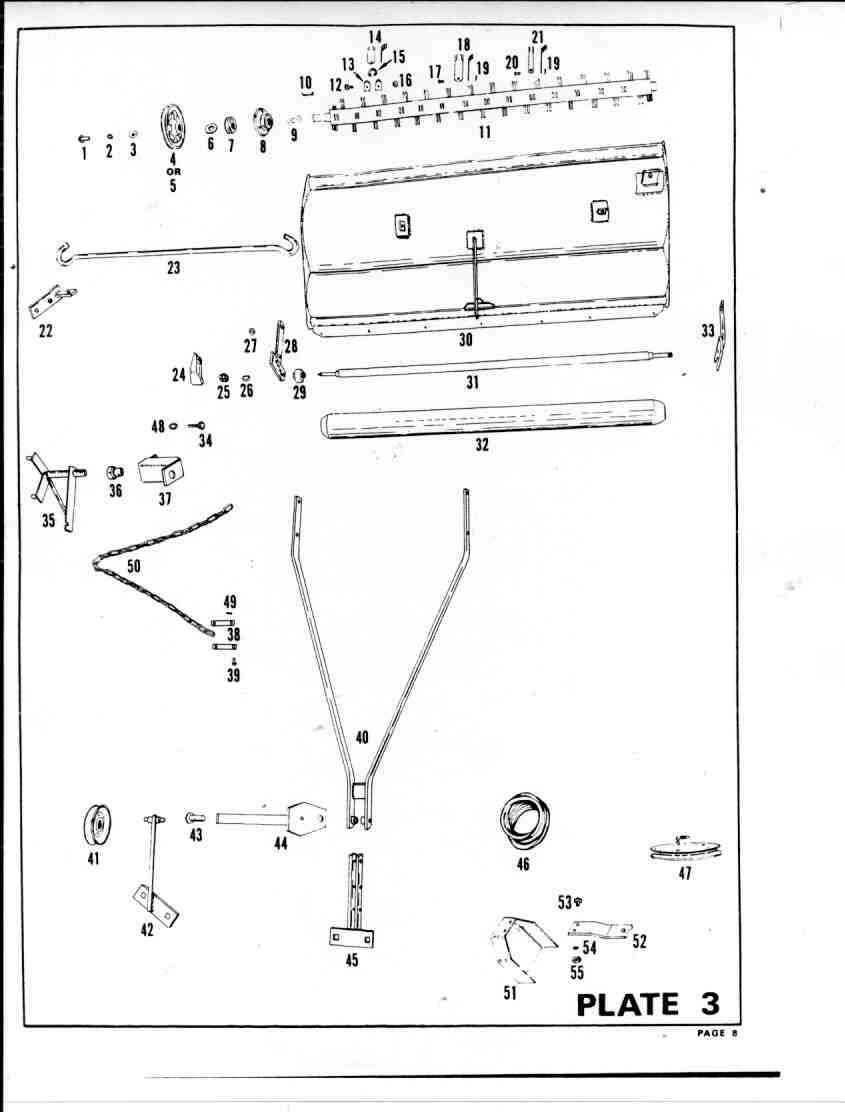

Understanding the structure of outdoor machinery starts with interpreting detailed visuals that map out its components. These guides offer a clear representation of how each element fits into the overall system, providing valuable insight into the assembly process. Learning to read these diagrams allows users to identify specific parts and understand their relationship to each other within the machine.

These visual aids typically use numbered labels or color codes to highlight individual components. Each label corresponds to a specific part, making it easier to locate and identify when performing maintenance or repairs. Familiarizing yourself with the symbols and layout will help speed up tasks and ensure that everything is reassembled correctly after service.

Pay close attention to the connections and flow of power between parts. Recognizing how energy and motion are transferred through the system helps in troubleshooting issues related to performance or mechanical failure. By studying these guides, you gain a deeper understanding of the machinery’s inner workings, making you better equipped to manage and repair it.

Essential Maintenance Tips for Lawn Equipment

Proper upkeep of your outdoor machinery ensures it remains in optimal condition for a longer period. Regular maintenance prevents unnecessary wear and tear, improves performance, and reduces the risk of unexpected breakdowns. By following simple yet effective care routines, users can extend the life of their tools and avoid costly repairs.

Key Maintenance Tasks

- Inspect the engine regularly for any signs of wear or damage.

- Clean the components thoroughly after each use to remove dirt and debris.

- Check and replace filters as necessary to ensure proper airflow and performance.

- Lubricate moving parts to prevent friction and ensure smooth operation.

Seasonal Care Guidelines

- Before storing the equipment for the winter, drain any remaining fuel to avoid clogging.

- Sharpen or replace the cutting elements to maintain efficiency during the next season.

- Check for rust and apply protective coatings to metal parts to prevent corrosion.

Regular inspections help detect potential issues early, making it easier to address minor repairs before they become more significant problems. Following a consistent maintenance routine will not only improve the machine’s performance but also ensure safety during use.