When working with agricultural machinery, it’s essential to have a clear understanding of its various elements and how they function together. These systems are designed to improve efficiency and accuracy during planting tasks, but like any complex equipment, they require proper maintenance and occasional repairs.

By familiarizing yourself with the layout and individual components of the machine, you can ensure its longevity and optimal performance. Knowing what each part does and how it fits into the overall system helps in troubleshooting, replacing worn-out components, and making adjustments as needed.

In this guide, we will explore the key elements of these machines, offering insights into their structure and providing tips for effective use. Whether you are a seasoned farmer or new to this technology, understanding the machine’s build is crucial for maintaining its peak functionality.

When working with agricultural machinery, it’s essential to have a clear understanding of its various elements and how they function together. These systems are designed to improve efficiency and accuracy during planting tasks, but like any complex equipment, they require proper maintenance and occasional repairs.

By familiarizing yourself with the layout and individual components of the machine, you can ensure its longevity and optimal performance. Knowing what each part does and how it fits into the overall system helps in troubleshooting, replacing worn-out components, and making adjustments as needed.

In this guide, we will explore the key elements of these machines, offering insights into their structure and providing tips for effective use. Whether you are a seasoned farmer or new to this technology, understanding the machine’s build is crucial for maintaining its peak functionality.

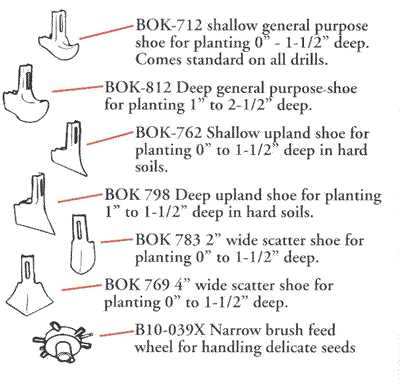

How to Read a Covington Planter Diagram

Understanding the layout of agricultural machinery is essential for effective maintenance and repairs. Visual guides often provide a detailed representation of a machine’s components and how they connect, offering a clear overview of its structure. Interpreting these illustrations can help identify parts quickly and efficiently, saving time and reducing potential errors during work.

Each section of the visual guide typically highlights different components, such as the frame, mechanisms, and control systems. It is important to familiarize yourself with the symbols and labels used, as they offer crucial information about the location and function of each element. Recognizing these key features allows for easier identification when dealing with troubleshooting or replacements.

Start by focusing on the general outline of the equipment, followed by more detailed areas that interest you. Pay attention to any color codes, numbering, or arrows that indicate the direction of movement or flow. Understanding these symbols and their meaning will give you a comprehensive grasp of the equipment’s layout and assist you in making informed decisions for proper maintenance and repairs.

Common Issues with Planter Parts

Even the most advanced farming equipment can encounter challenges over time. Regular use, harsh conditions, and wear and tear can lead to a variety of issues that impact performance. Identifying these problems early is crucial for preventing further damage and ensuring the machinery continues to operate at its best.

One common issue is wear on moving components, which can result in reduced efficiency or malfunction. Parts such as gears, belts, and sprockets are especially vulnerable to wear, often causing improper alignment or difficulty in operation. It’s important to inspect these regularly to detect any signs of damage or degradation.

Another frequent concern is clogging or blockages in the system. Debris, soil buildup, or other foreign materials can obstruct moving parts, leading to delays in operation and potential damage. Regular cleaning and maintenance are essential to prevent these issues from becoming more serious.

Finally, improper adjustments or misalignments can lead to uneven operation, such as inconsistent depth or spacing during planting. Ensuring that all components are properly calibrated is key to avoiding this issue and achieving optimal results with each use.