Maintaining outdoor power tools requires a solid understanding of their individual components and how they work together. A clear illustration of these parts can significantly simplify repair or replacement tasks. Whether you’re a professional or a DIY enthusiast, having access to detailed breakdowns of tool assemblies helps you stay prepared for any maintenance needs.

Familiarizing yourself with how various elements are arranged within the machine not only speeds up the repair process but also ensures that parts are correctly reassembled. A comprehensive guide provides clarity on which components need attention and helps avoid mistakes during replacements. Knowing your equipment inside and out guarantees both efficiency and longevity in your tool’s performance.

Understanding Equipment Component Layout

Knowing the arrangement of essential components within a tool is crucial for effective maintenance. Each element serves a specific function, and understanding how they interconnect allows for smoother repairs and replacements. This knowledge empowers users to identify issues quickly and address them without unnecessary delays.

Key Elements and Their Functions

Various components of the tool work together to ensure smooth operation. From the motor to the cutting mechanisms, each piece plays an integral role. Recognizing how these parts contribute to the overall performance of the machine can help you determine which areas may need attention during maintenance.

Reassembly and Troubleshooting

When it comes time to replace or reassemble individual parts, having a clear layout is essential. Knowing where each element fits helps prevent errors and ensures proper function once the tool is back together. Understanding the layout also aids in troubleshooting, enabling you to pinpoint the source of any issues efficiently.

How to Identify Equipment Components

Properly identifying each element of a tool is key to effective maintenance. Whether you’re replacing worn-out parts or troubleshooting issues, recognizing the specific components and understanding their role in the machine’s function can save time and effort. Knowing where to look and what to look for is essential for anyone managing the upkeep of outdoor equipment.

Common Identification Methods

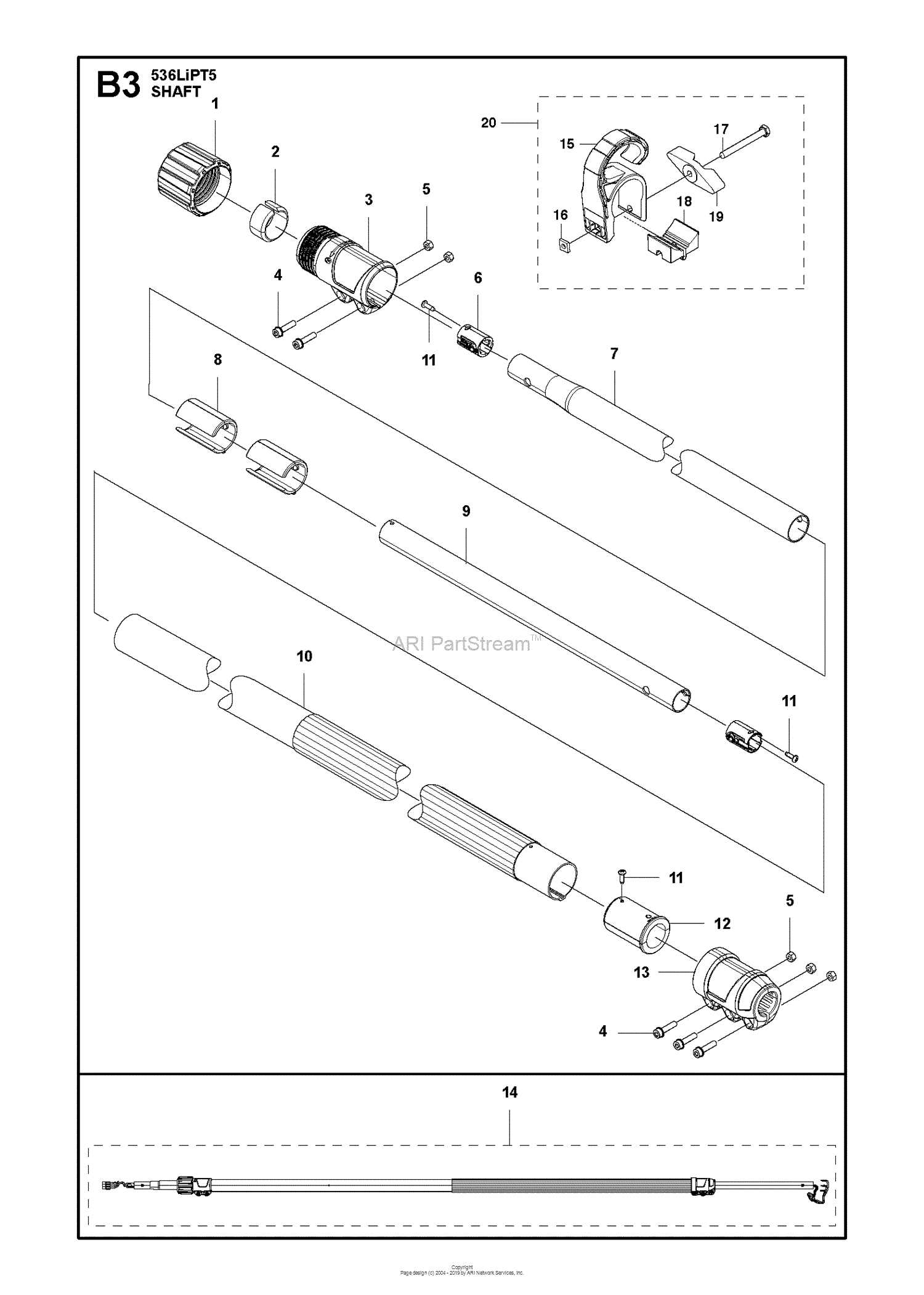

One of the simplest ways to identify components is by referencing a manual or a detailed guide that clearly labels each element. This visual reference helps distinguish the various parts, whether it’s the engine, the shaft, or the control mechanisms. Taking note of the shape, size, and function of each piece will improve your ability to spot problems quickly and efficiently.

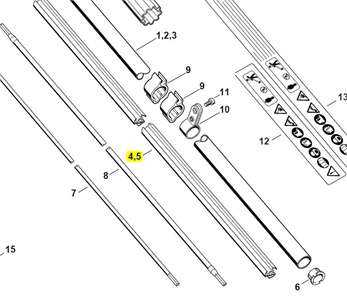

Using Visual Guides and Markings

Many tools include markings or part numbers etched directly onto the components, which can further assist with identification. These identifiers can be cross-referenced with a manual or a part number database to ensure you have the correct replacement or repair item. Visual guides or exploded views are also helpful for understanding how each part fits into the overall structure.

Repairing and Replacing Tool Components

When it comes to fixing or replacing worn-out elements in a tool, knowing the right procedures and having the proper replacements is essential for maintaining functionality. Whether you’re dealing with a malfunctioning mechanism or replacing a broken component, understanding the correct steps ensures that the machine continues to operate efficiently. Timely repairs can extend the lifespan of your equipment and prevent further issues.

Step-by-Step Repair Process

Start by identifying the specific component that needs attention. Once identified, carefully disconnect any power sources and ensure safety before disassembling the tool. Use a manual or guide to follow the proper disassembly steps. This will prevent damage to other parts and ensure that each element is replaced or repaired correctly. Always check the condition of surrounding components during this process.

Choosing the Right Replacement Parts

When selecting a replacement, it is crucial to use the correct part for your model. Refer to the tool’s manual or an online parts catalog to find the right specifications. Using parts that match the original design will help maintain the tool’s performance and avoid complications. If necessary, consult a professional to ensure compatibility and proper installation.