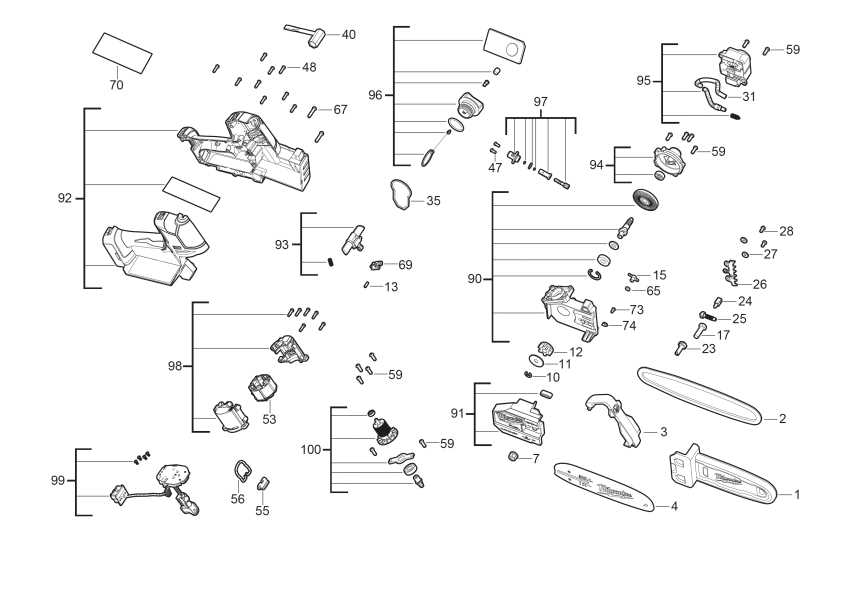

Understanding the inner workings of your chainsaw is crucial for proper maintenance and efficient operation. A clear illustration of its various components helps in identifying and replacing parts that may wear out over time. This guide provides a detailed overview to assist you in navigating and interpreting the technical drawings that depict the essential elements of your equipment.

By gaining familiarity with these schematics, you will be able to identify each individual piece and its function. This knowledge is key when it comes to performing routine inspections, troubleshooting issues, or making necessary replacements. Knowing your chainsaw inside and out ensures it continues to run smoothly and effectively for longer periods.

Properly maintaining and replacing parts can save you time and money by preventing unnecessary repairs. Familiarize yourself with the layout and functions of each component to extend the lifespan of your tool and improve its performance during every use.

Understanding the Chainsaw Components

In any mechanical tool, the intricate components play a vital role in ensuring its optimal functionality. When it comes to a cutting machine, a clear understanding of how each part interacts with one another is essential for both performance and longevity. Recognizing the main elements and their specific functions helps in maintaining the tool and performing accurate repairs when necessary.

Key Elements of the Tool

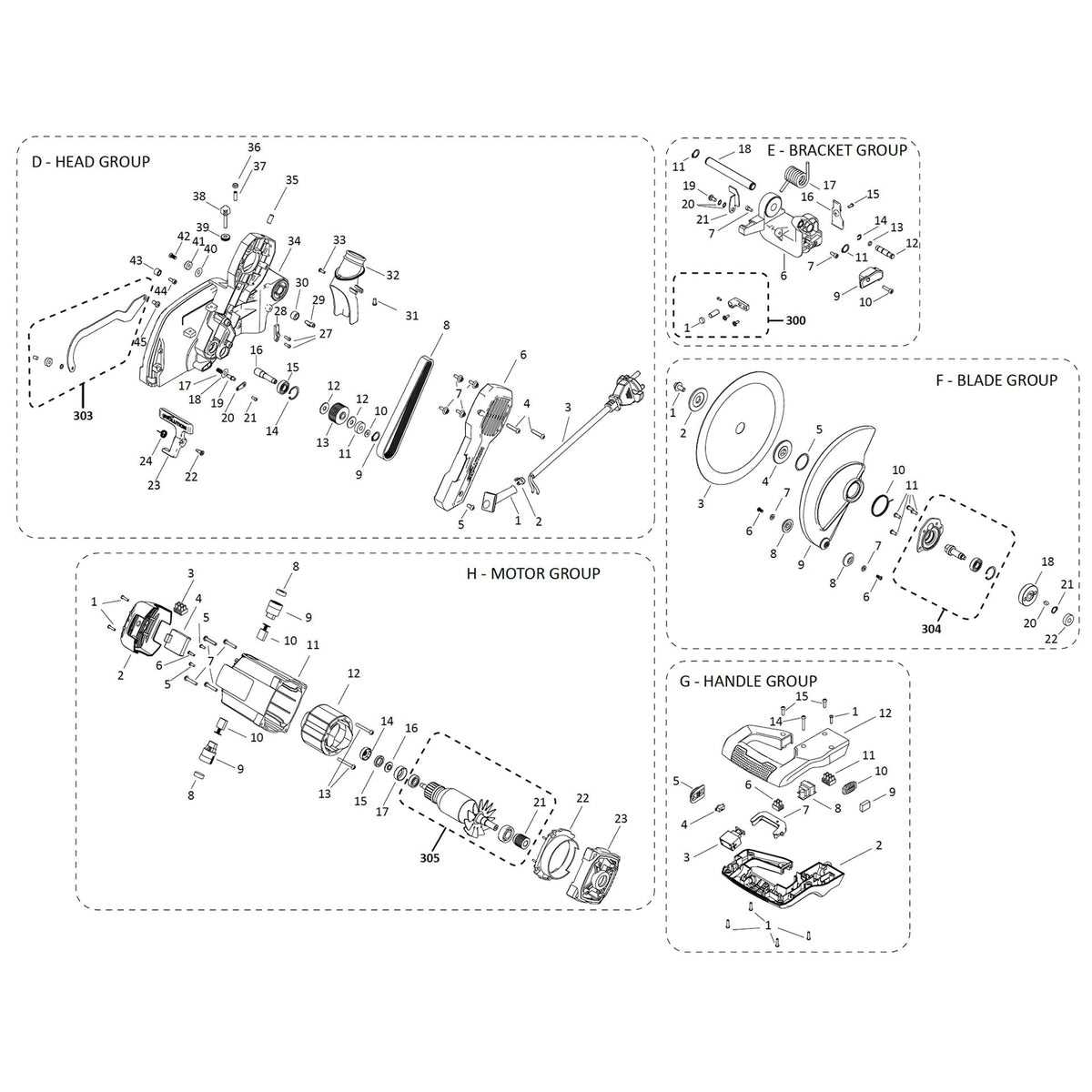

The core components of the chainsaw include the engine, cutting mechanism, and drive system, among others. Each part serves a unique purpose, from powering the tool to controlling the movement of the chain. Understanding how these pieces work together allows users to spot any issues early on, preventing more significant problems down the line.

How Components Affect Performance

Every element of the chainsaw contributes to its overall efficiency. Whether it’s the engine’s power output, the tension of the chain, or the lubrication system, each factor has an impact on the tool’s effectiveness during operation. Regular maintenance and proper knowledge of these elements ensure that your chainsaw remains a reliable and durable tool for years to come.

How to Read the Tool Component Layout

Understanding a technical illustration of your tool’s internal structure is essential for accurate maintenance and repairs. These drawings provide a visual representation of the various parts, highlighting their placement and interconnections. Being able to interpret these layouts will help you identify which pieces need attention or replacement during upkeep.

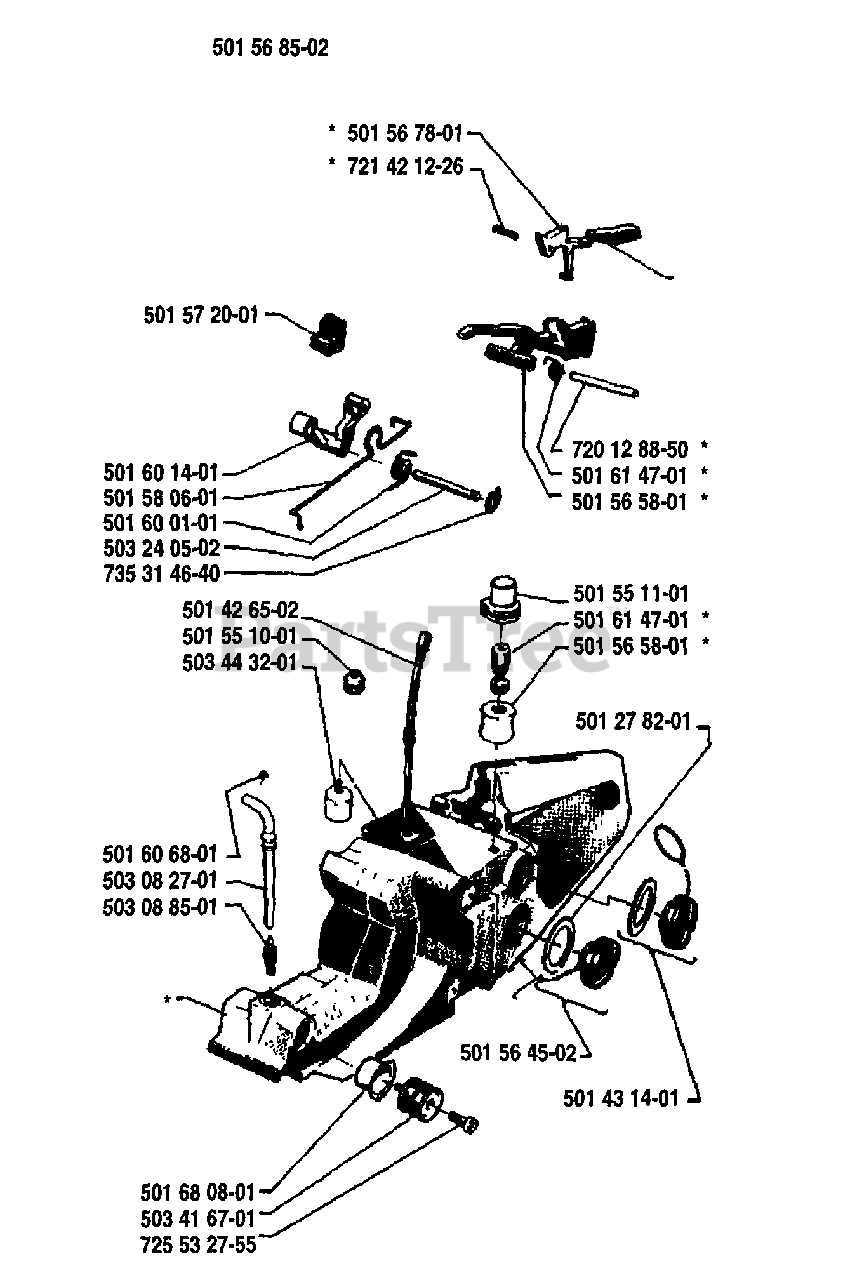

The layout typically uses labeled references to show each component. Pay attention to the numbering or lettering system, as these notations guide you to specific parts within the system. By following these markers, you can efficiently locate the piece in question and understand its role in the overall function of the machine.

Common Issues and Part Replacements

Even the most reliable tools can experience wear and tear over time, leading to performance issues. Understanding common problems that arise in these machines helps in diagnosing faults early and ensuring timely replacements. Identifying which components are most likely to fail allows for efficient repairs, preventing more significant breakdowns.

Some frequent issues include chain movement problems, engine misfires, or overheating. These can often be traced back to specific components, such as the drive system, fuel lines, or the tensioning mechanism. Replacing the affected part with a suitable replacement is often the key to restoring functionality and prolonging the lifespan of the tool.