Proper maintenance and repair of heavy equipment rely heavily on understanding its internal structure. A visual guide that clearly shows each individual component can be a crucial tool for anyone working with complex machinery. Knowing how various elements are arranged and connected simplifies troubleshooting and enhances the overall service process.

Identifying each piece is the first step towards efficient repairs. A detailed layout helps technicians locate malfunctioning sections quickly, minimizing downtime. It’s essential to have a clear visual reference to ensure all parts are functioning properly and to prevent further damage due to overlooked issues.

In this guide, we will walk through how to interpret these visual aids, focusing on essential parts and their roles in maintaining smooth operations. With a solid understanding, you can confidently approach repairs and replacements, ensuring your equipment performs at its best.

Understanding Machinery Components

Every machine consists of various elements that work together to ensure smooth and efficient operation. Understanding these individual components and how they interact is key to maintaining optimal performance. Whether you’re working on a small engine or a larger, more complex machine, having knowledge of the inner workings allows for more effective diagnostics and repairs.

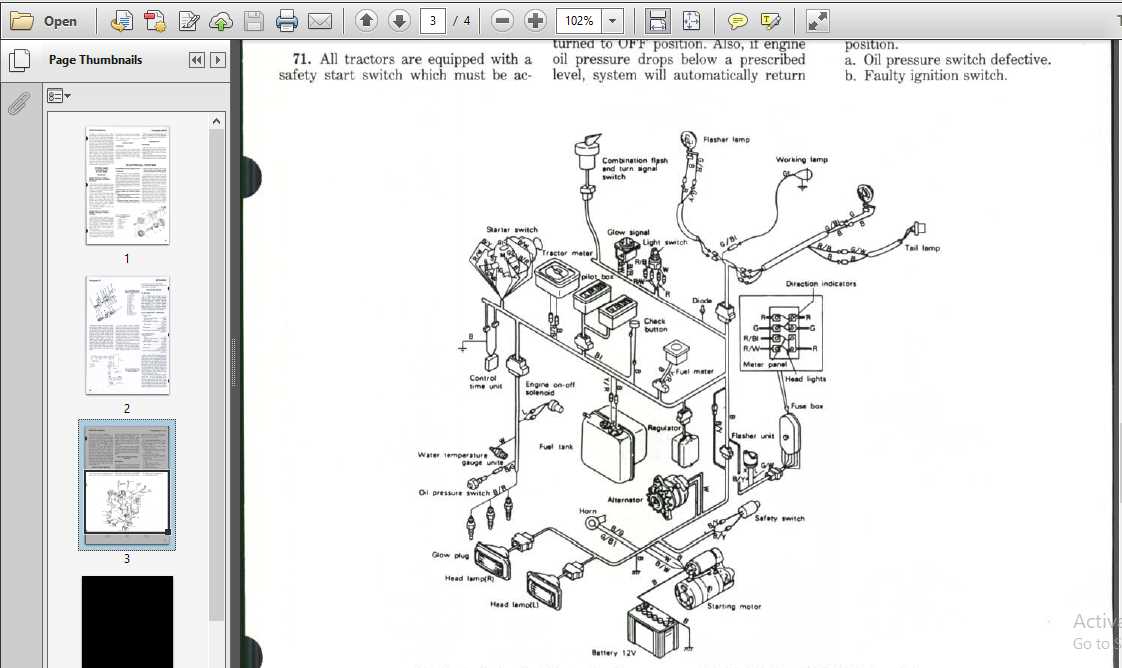

Key elements of any machine include the engine, transmission, hydraulic system, and electrical components. Each part plays a specific role, contributing to the overall functionality of the equipment. Familiarity with these sections can help identify potential issues and determine the necessary steps for troubleshooting.

Additionally, understanding the connections between these components is crucial for proper maintenance. Without a clear picture of how everything fits together, repairs may be delayed or incomplete, potentially leading to further damage. An in-depth understanding ensures that each element operates in harmony, extending the lifespan of the machine.

How to Read a Machinery Components Layout

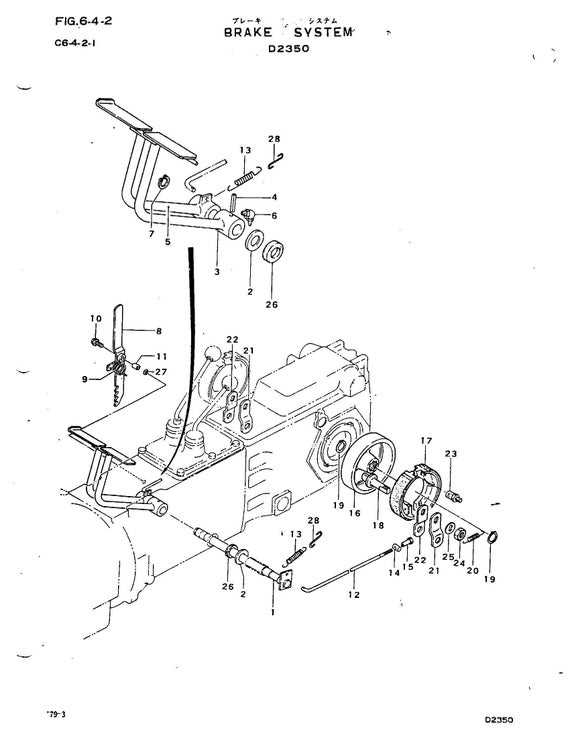

Understanding a machine’s layout is crucial for effective maintenance and repair. These visual guides provide a detailed view of how the different elements are arranged and connected. By interpreting these layouts, you can easily identify specific components and their functions, making repairs and troubleshooting more efficient.

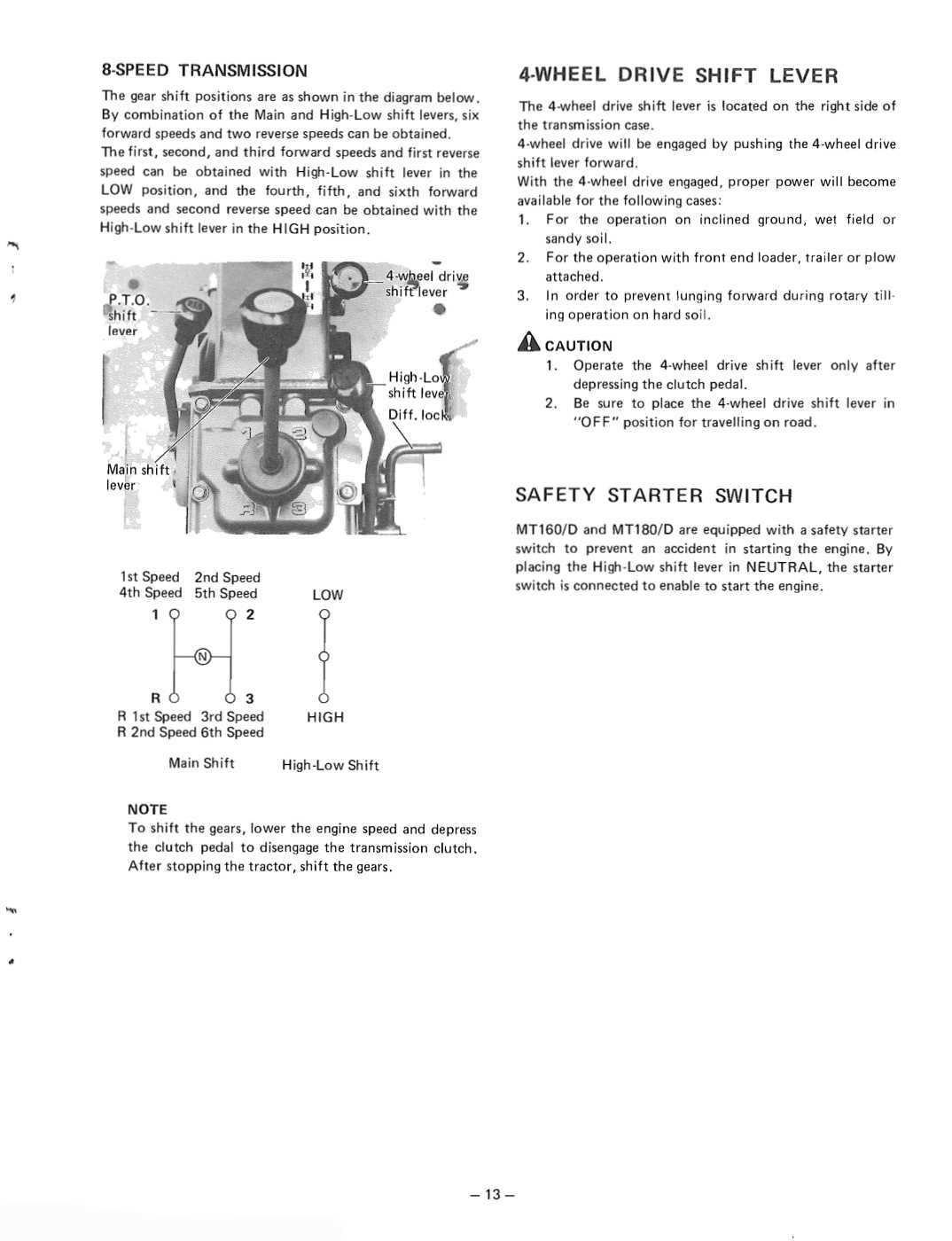

Start by focusing on the overall structure, noting the arrangement of major sections such as the engine, hydraulic system, and transmission. From there, you can zoom in on the smaller components within each section, recognizing their specific roles and relationships to other parts. Each part will often be labeled with numbers or symbols that correlate with the corresponding components in the parts list.

It is important to understand the legend or key included in most layouts, as it helps clarify the meaning behind various markings. These can include arrows indicating movement or lines connecting different elements, showing how they work together. With practice, you’ll become more efficient in navigating the layout and using it as a valuable tool for repairs.

Common Machinery Repairs and Components

Machines, like any other complex system, require regular attention to maintain their efficiency and longevity. Over time, certain components wear out or experience failures, making repairs inevitable. Identifying and replacing these damaged elements is essential to keep operations running smoothly and prevent further damage.

Engine and Transmission Issues

The engine and transmission are often at the heart of many mechanical issues. Common problems include overheating, oil leaks, or worn-out gears. Regular checks of these systems can help detect early signs of wear, allowing for timely repairs before they lead to complete failure. Maintaining proper lubrication and monitoring fluid levels are key steps in preventing these issues.

Hydraulic and Electrical System Failures

Another common area for repairs involves the hydraulic system and electrical components. Leaking hoses, faulty pumps, or electrical short circuits can disrupt the machine’s functionality. Replacing worn hoses or repairing wiring can significantly improve performance and extend the life of the machine. Regular inspection of the hydraulic system is vital to avoid unexpected breakdowns.