Every household or professional kitchen contains various tools that make everyday tasks easier. Understanding how these devices work and the individual elements they consist of is essential for effective use and maintenance. Each component plays a crucial role in ensuring the smooth operation of the system.

Knowing the function and structure of each piece can help in identifying issues, performing repairs, or simply improving your understanding of the equipment. By familiarizing yourself with these essential components, you can extend the life of your tools and enhance their performance.

Common challenges often arise when a specific part malfunctions or needs replacing. Being able to visually identify and understand the key sections of the system can make troubleshooting much more straightforward. Whether it’s wear and tear, clogging, or damage, addressing these problems promptly will help maintain efficiency.

Understanding the Components of a Sink Sprayer

In any water-dispensing system, various elements work together to ensure proper functionality. These components can range from the control mechanisms to the delivery system, each serving a specific purpose. A deeper understanding of how each section interacts will help you identify potential issues and make repairs with confidence.

The primary function of such a device is to deliver water where it is needed. To achieve this, the assembly relies on a combination of hoses, valves, and nozzles. Each part plays a distinct role in ensuring water flows smoothly and consistently, with a design that allows for easy maneuvering and efficient usage.

When maintaining or replacing any piece of this system, it is essential to understand the function of each individual component. This knowledge helps with troubleshooting and ensures that any replacements are made accurately. Familiarity with these elements will also allow you to maximize the effectiveness of the system, reducing the need for frequent repairs.

How to Identify Sink Sprayer Parts

Recognizing the individual components of a water-dispensing system can be challenging, especially for those unfamiliar with its design. However, understanding each piece’s function is crucial for effective maintenance or repair. By examining the device closely and identifying key features, you’ll be able to spot issues more easily and make necessary adjustments.

Examining the Main Assembly

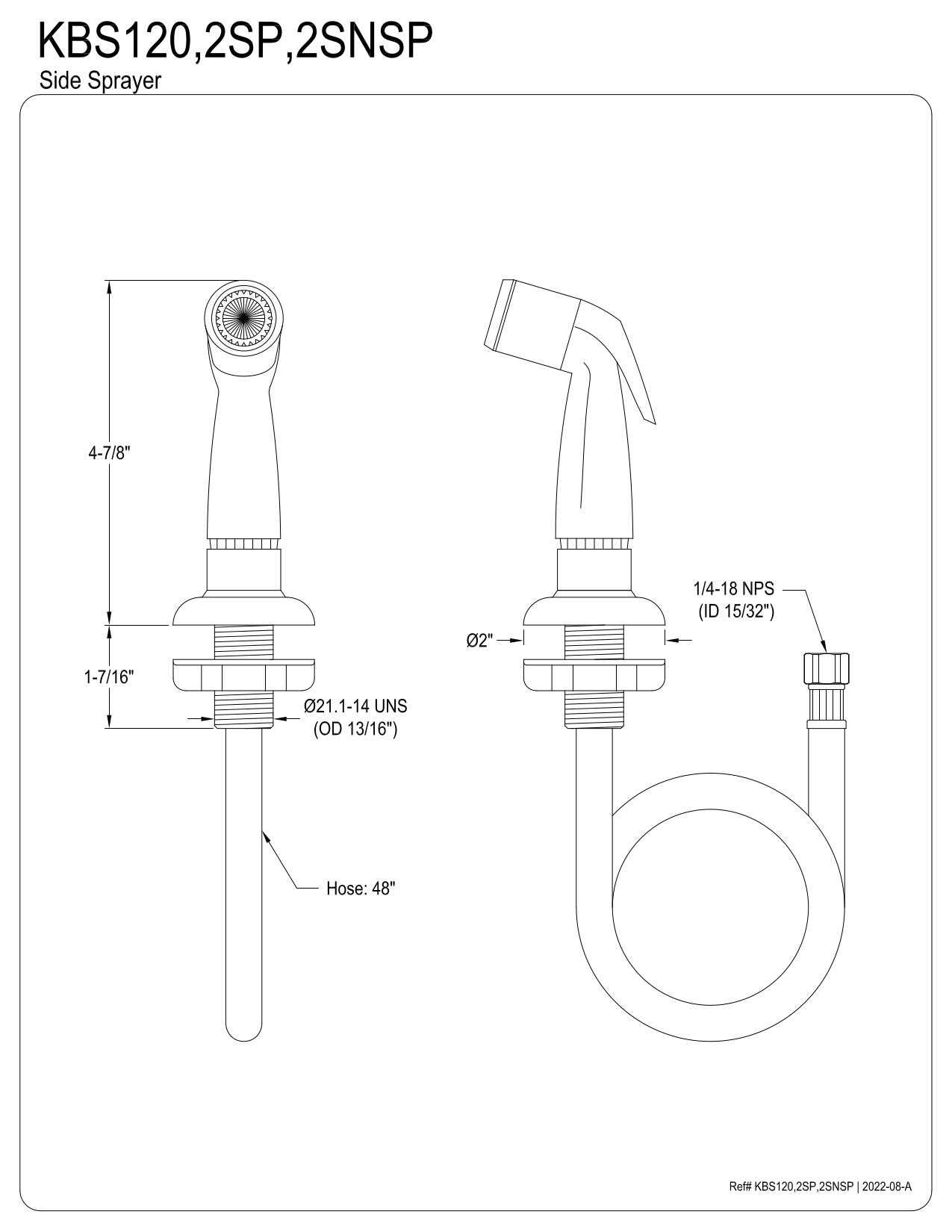

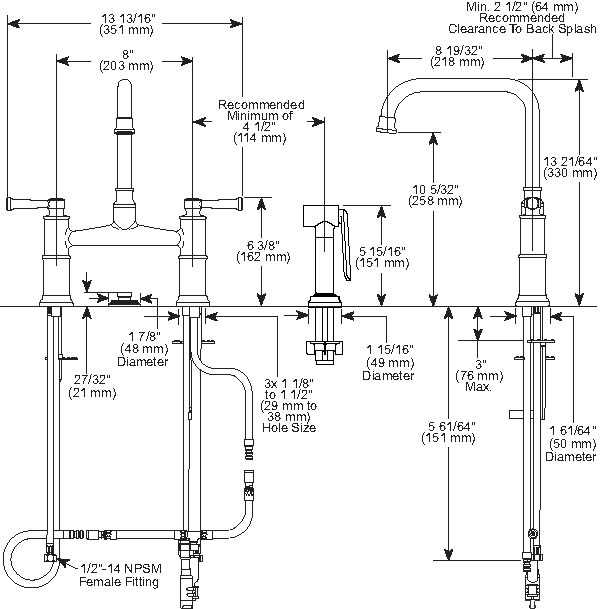

Start by closely inspecting the entire assembly. The main body usually contains the most visible elements, such as the handle or control mechanism. This section is responsible for managing water flow and typically includes a button or lever to regulate the pressure. Understanding the placement of these controls will give you an idea of how the rest of the system functions.

Identifying Smaller Components

Once the primary sections are understood, focus on the smaller pieces. These include hoses, connectors, and fittings that work in unison to deliver water. The hoses may show wear over time, while connectors can sometimes become loose or damaged. Knowing what each smaller piece looks like and how it interacts with the others will help in troubleshooting and repairing the unit efficiently.

Common Issues with Sink Sprayer Parts

Like any mechanical system, water-dispensing devices are prone to wear and tear. Over time, certain components may experience malfunctions or performance issues, leading to inconvenience and inefficiency. Understanding these common problems can help with timely repairs and ensure that the system continues to function smoothly.

Some of the most frequent issues involve the flow of water or the condition of various components. Below are a few of the most common problems that can arise:

- Low Water Pressure: Often caused by clogged or damaged hoses, this issue can make it difficult to achieve a strong water stream.

- Leaking Connections: Loose or worn-out connectors can lead to leaks, which waste water and may cause damage to surrounding areas.

- Clogged Nozzles: Mineral buildup or debris can block water flow, affecting the efficiency of the system and requiring cleaning or replacement.

- Faulty Control Mechanisms: When the control lever or button fails to regulate water flow, it can lead to either excessive or insufficient pressure, disrupting normal operation.

Addressing these issues early on can save both time and money, preventing further damage and ensuring the device remains effective for years to come.