When it comes to maintaining and repairing a lawn tractor, one of the most critical systems to consider is the control mechanism that ensures smooth operation. Proper knowledge of the different elements involved in this system can greatly improve both performance and reliability. This section will guide you through the crucial components that make up the control system, providing valuable insights for anyone looking to troubleshoot or replace specific parts.

Identifying each part within the mechanism is vital for detecting issues early and ensuring safe operation. By understanding how each component functions and how they work together, you can save time and resources during repairs. Additionally, a clear understanding will help in making informed decisions when selecting replacement parts or upgrading certain features of the system.

In this article, we will break down the various elements that play a role in the control system, highlighting their function and how they contribute to the overall performance of the machine. Whether you’re an experienced technician or a first-time owner, this information will be valuable in keeping your lawn tractor in top condition.

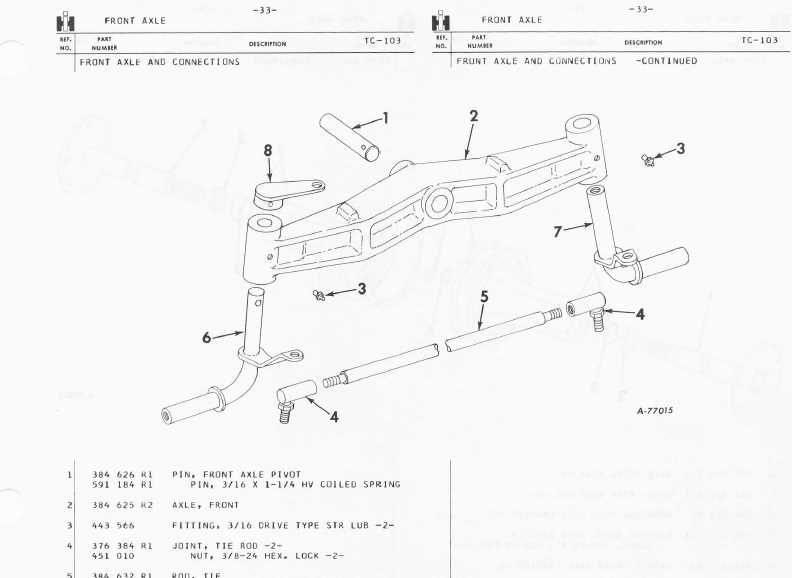

Cub Cadet LT1050 Steering System Breakdown

Understanding the functionality of the control mechanism in a lawn tractor is essential for proper maintenance. This system consists of various interconnected components that work together to allow precise and smooth handling of the machine. By recognizing how each element interacts, you can identify potential issues and address them before they lead to significant malfunctions.

At the core of this system, there are key elements such as the transmission linkages, wheel connections, and the control mechanism itself. These parts ensure the vehicle responds accurately to the operator’s movements. Regular inspection and understanding of these components will help maintain the overall functionality of the machine, minimizing wear and tear over time.

In this section, we will break down the critical components of this mechanism, providing a clear overview of how each one contributes to the efficient operation of the lawn tractor. From the connection points to the inner mechanisms, this guide will offer a comprehensive understanding for better upkeep and repairs.

Understanding the Key Steering Components

To ensure the proper operation of a lawn tractor, it’s crucial to have a solid understanding of the essential components that make up its control system. Each part plays a specific role in translating the operator’s actions into movement, allowing for precise navigation and handling. Familiarizing yourself with these components can make maintenance and troubleshooting much easier.

Below is an overview of the most important elements that form this system:

- Transmission Linkages: These connections facilitate the transfer of motion from the operator’s controls to the driving mechanism.

- Wheel Connectors: These parts directly link the wheels to the system, enabling the turning and movement of the machine.

- Control Mechanism: This central unit receives input from the operator and sends signals to adjust the direction and speed of the vehicle.

- Bearings and Bushings: These components help reduce friction, ensuring smooth movement and preventing wear and tear over time.

By understanding each component’s role, you can identify and resolve issues more efficiently, ensuring that the machine operates as intended for years to come.

How to Identify Steering Issues in LT1050

When a lawn tractor begins to experience control problems, it is essential to recognize the signs early to avoid further damage. Identifying issues with the control system can help pinpoint the malfunctioning components, allowing for prompt repairs. This section will guide you through the common symptoms and provide tips on how to detect potential problems in the system.

Some of the most frequent issues include:

- Unresponsive Turning: If the vehicle fails to respond properly when turning, the problem could lie with the linkages or connectors between the control system and the wheels.

- Excessive Play in the Controls: A loose or wobbly feel in the steering mechanism often points to worn bearings or other components that need attention.

- Uneven Handling: When the machine pulls to one side or moves unpredictably, it may indicate a misalignment or damage to the control components.

- Noisy Operation: Grinding or squeaking sounds during movement typically suggest friction caused by worn-out bushings or misaligned parts.

If you notice any of these signs, it’s important to investigate the components that could be causing the problem. Regular maintenance and periodic checks will help prevent these issues from escalating, keeping the tractor functioning smoothly.