When it comes to maintaining any engine-driven equipment, knowing the internal elements and their functions is crucial. Each component plays a specific role in ensuring the system operates smoothly and efficiently. Whether you’re a beginner or experienced, understanding these parts can save you time and reduce the need for professional repairs.

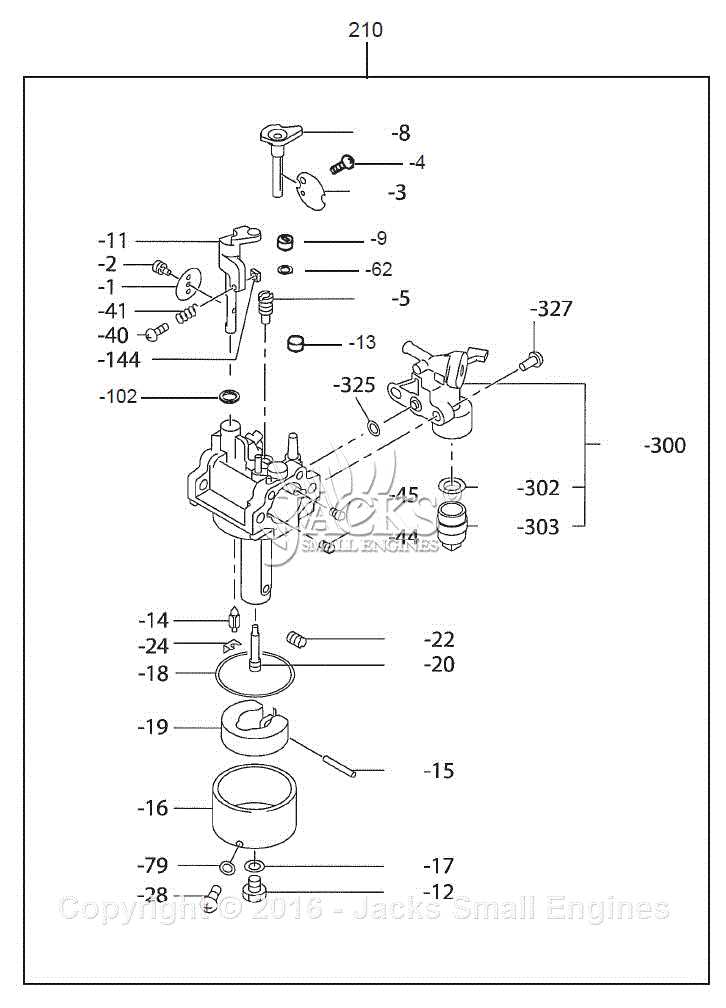

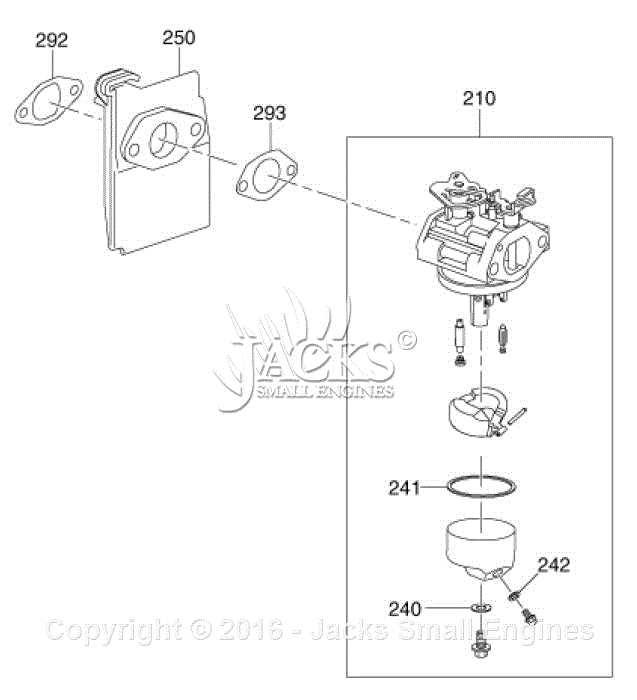

Visual aids like illustrations can make it easier to identify and comprehend the setup of the engine. By referring to detailed schematics, you can pinpoint the location and role of every crucial component. This knowledge helps streamline the repair process and allows for more effective troubleshooting.

Regular upkeep requires attention to these elements, especially if you’re noticing issues or performing a routine service. Proper maintenance not only extends the lifespan of your equipment but also enhances its performance. Taking a proactive approach ensures a hassle-free experience and keeps everything functioning at its best.

Understanding Engine Components

Every engine-driven system relies on a variety of components, each essential for the machine’s performance. Understanding these elements is the first step to effective maintenance. Each piece has its unique function, contributing to the overall efficiency and durability of the equipment. Knowing how to recognize and troubleshoot potential issues can prevent costly repairs and extend the machine’s lifespan.

Key Components of the Engine

The heart of any engine consists of multiple key components that work together seamlessly. Below is a list of essential elements found in most systems:

- Fuel System: This includes the fuel tank, filter, and lines, which ensure proper fuel flow for engine operation.

- Air Intake: Proper airflow is vital for combustion. The intake system consists of filters and ducts that regulate air entering the engine.

- Ignition System: This system includes the spark plug, coil, and wiring, essential for initiating combustion.

- Exhaust System: Responsible for removing combustion byproducts, this includes pipes and mufflers.

Maintaining Optimal Performance

For smooth and consistent performance, it is necessary to regularly inspect and maintain each of these components. Neglecting even a small issue can result in system failure, impacting efficiency. Regular checks on fuel, air, and exhaust flow are necessary for avoiding potential damage.

- Check Fuel and Air Filters: These should be cleaned or replaced periodically to prevent clogging.

- Inspect Spark Plugs: Faulty plugs can result in poor ignition, causing starting issues.

- Ensure Exhaust System Integrity: Leaks or blockages can cause overheating or inefficient engine operation.

How to Identify Engine Components

Identifying the various elements of an engine-driven machine is essential for understanding its functioning and ensuring proper maintenance. Familiarizing yourself with the key components can help with both routine inspections and repairs. Recognizing parts by their shapes, sizes, and functions is the first step in troubleshooting and replacing any worn-out elements.

Locating Major Components

Start by understanding the location of critical components that are most commonly replaced or serviced. These elements often need frequent attention, and knowing where they are located is vital for quick fixes:

- Engine Housing: This is the outer casing that protects the internal mechanisms of the system.

- Fuel Delivery: Check the fuel lines and filters, ensuring they are free from blockages.

- Ignition Mechanism: The ignition coil and spark plug are critical for starting the engine. Locate these to ensure proper spark initiation.

Using Visual Guides for Identification

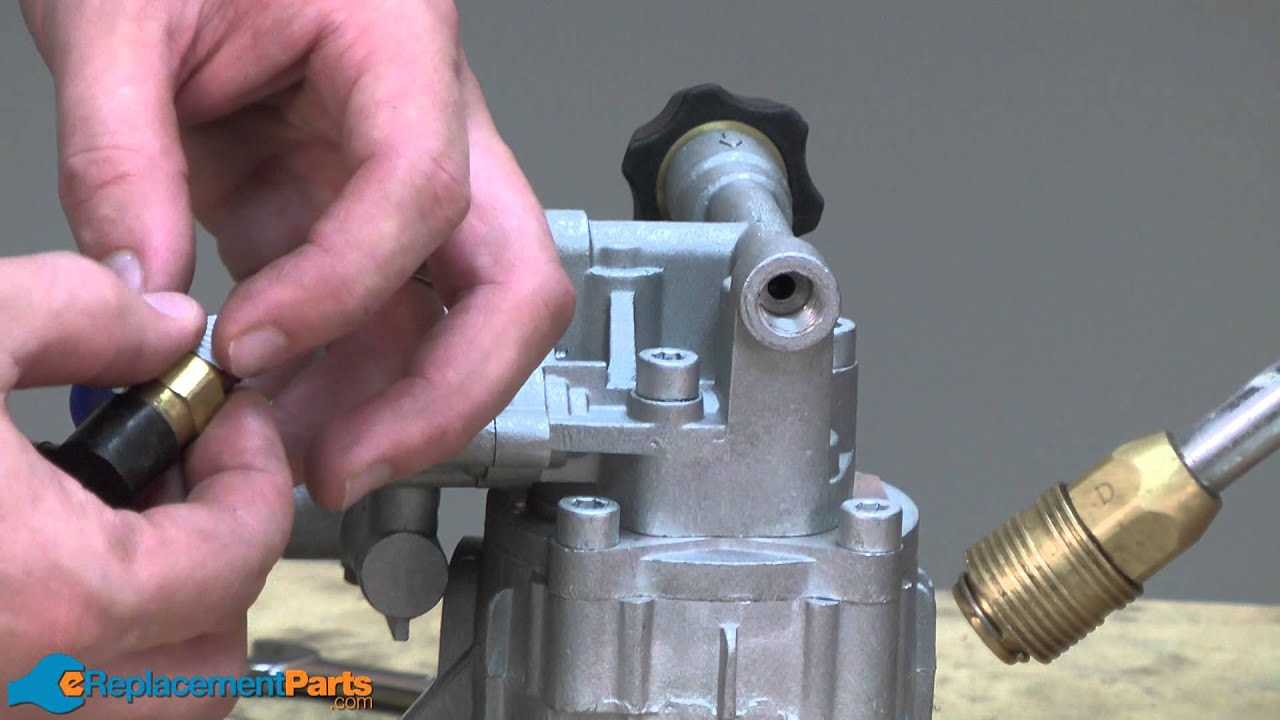

Often, a visual guide can be extremely helpful in identifying components. Detailed illustrations or manuals will show the precise location of each part, allowing you to match their physical form with their function. Having a reference ensures you’re not left guessing when it comes to repairs or upgrades.

- Check Manuals: Consult the user manual for a labeled diagram that clearly shows all key components.

- Use Online Resources: Many manufacturers offer online diagrams or tutorials to assist with identification.

Maintenance Tips for Engine Components

Regular upkeep of your equipment is key to ensuring its longevity and optimal performance. Proper maintenance helps prevent breakdowns, minimizes the need for repairs, and ensures all systems run smoothly. By following a few essential tips, you can avoid common issues and keep your machine in excellent condition for years to come.

Routine Cleaning and Inspections

Maintaining cleanliness and performing frequent inspections can go a long way in preserving the health of the engine. Over time, dust, dirt, and debris can accumulate and negatively impact performance. Regularly clean critical components and inspect them for signs of wear or damage.

- Clean Fuel System: Regularly check for any blockages or debris in the fuel lines and filter.

- Air Filters: Clean or replace air filters to maintain proper airflow and ensure efficient combustion.

- Check for Leaks: Inspect all hoses, seals, and connections for any signs of leaks that could hinder performance.

Component Lubrication and Replacement

Proper lubrication is essential for moving parts to operate smoothly. Without the right lubrication, friction can cause excessive wear and potential failure. Additionally, make sure to replace worn-out components promptly to prevent more serious issues down the line.

- Lubricate Moving Parts: Regularly lubricate parts such as the pump, bearings, and other moving components to reduce friction.

- Replace Worn Seals: Worn seals can cause leaks and inefficiency, so replace them as soon as they show signs of damage.