Proper maintenance and repair of outdoor machinery are crucial for ensuring smooth operation and longevity. When you have a machine designed for heavy-duty outdoor tasks, understanding its individual elements is key to troubleshooting and maintaining its performance.

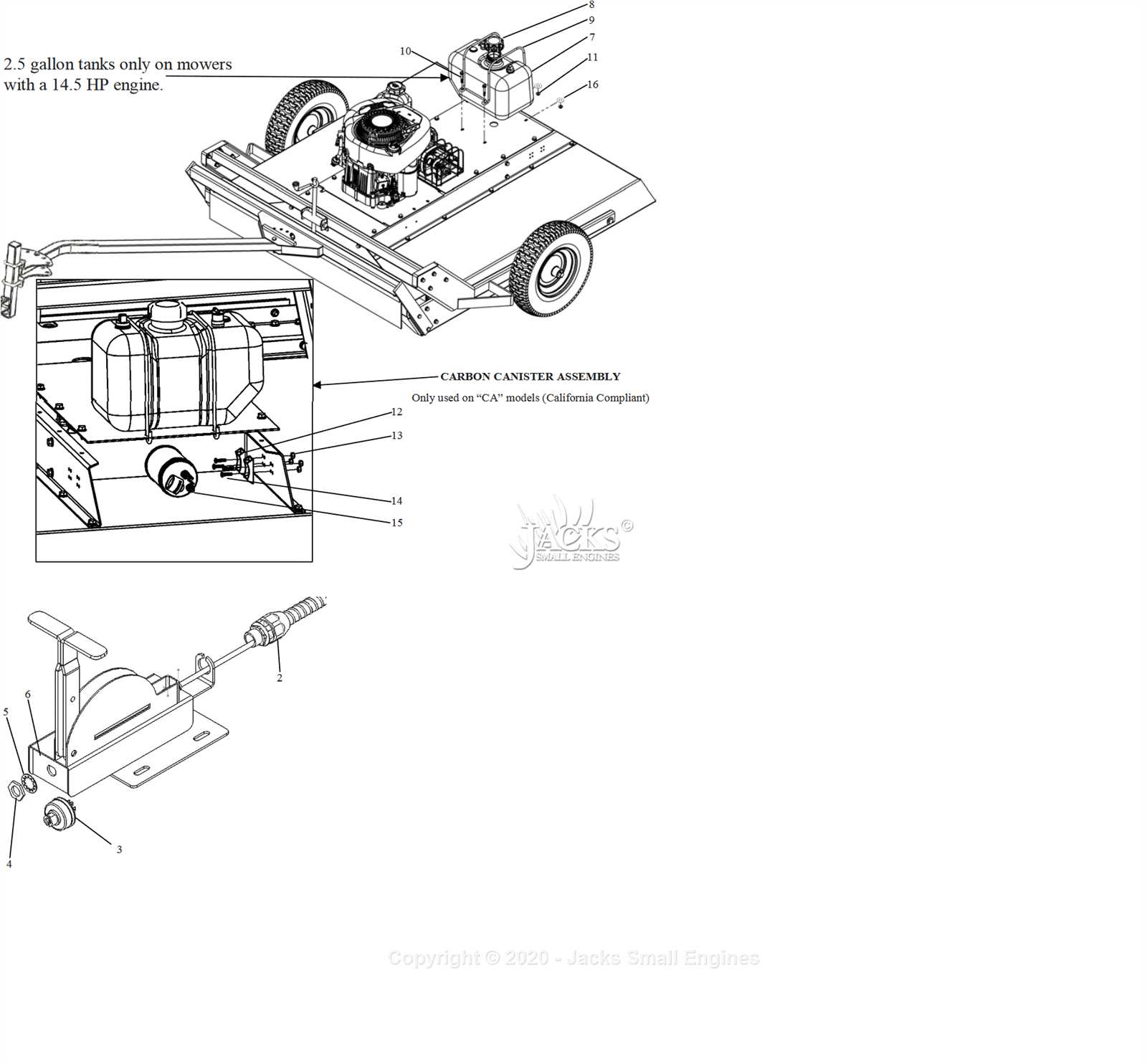

Whether you’re looking to replace a damaged item or simply want to familiarize yourself with the various parts, knowing their function and location can save you time and effort. A clear guide showing the arrangement of these components is invaluable for anyone seeking to perform repairs or upgrades on their equipment.

Identifying each section and learning about its role in the overall mechanism will help ensure you are equipped to handle any maintenance tasks efficiently. Understanding how these pieces interact with each other also contributes to preventing future issues.

Understanding Swisher 44” Mower Parts

Every outdoor machine built for rough terrain and heavy-duty work consists of multiple essential elements, each contributing to its functionality. By understanding the various components, users can effectively maintain and repair their equipment. Recognizing the purpose of each part ensures that issues can be quickly addressed, extending the lifespan and enhancing performance.

These machines feature several key components that work together to create a seamless experience for the operator. From the drive system to the cutting mechanism, each section serves a specific function, contributing to the overall effectiveness of the tool. Familiarizing yourself with these pieces not only aids in troubleshooting but also helps when performing routine maintenance tasks.

Knowing how each part interacts with the rest of the system makes it easier to identify any potential problems. Additionally, having a clear understanding of the layout can prevent unnecessary damage and help in making informed decisions when purchasing replacement parts.

How to Identify Essential Components

Recognizing the critical components of your outdoor equipment is the first step toward proper maintenance. Identifying each part and understanding its function will allow you to diagnose problems more effectively and address issues promptly. By focusing on the key sections, you can make informed decisions about repairs and replacements.

Start by familiarizing yourself with the primary sections of the machine. Look for components like the drive mechanism, control system, and the cutting mechanism. These are the core elements that keep the equipment running smoothly. Once you understand how these parts interact with each other, you will be able to spot any signs of wear or damage more easily.

Having a visual guide or reference can be incredibly helpful when pinpointing specific elements. This will allow you to compare the physical parts with their corresponding names and locations, ensuring that you can replace or repair the right components without confusion.

Maintaining Your Swisher Mower Effectively

To ensure optimal performance and longevity of your outdoor machinery, regular maintenance is essential. Keeping your equipment in top condition reduces the likelihood of breakdowns and enhances its efficiency during use. A well-maintained machine operates smoothly, saving both time and money in the long run.

Routine Inspection and Cleaning

Start by inspecting the key components of your equipment after each use. Look for any signs of wear, damage, or accumulation of dirt. Cleaning the machine, especially the areas that come in direct contact with debris, will prevent buildup and extend its lifespan. Regularly checking the fuel system, filters, and blades will also contribute to better performance.

Lubrication and Component Replacement

Proper lubrication is essential for reducing friction and preventing premature wear on moving parts. Make sure all the necessary parts are well-lubricated, as recommended by the manufacturer. If any components are worn or damaged, replacing them promptly will help maintain the overall functionality of the machine. Regular maintenance schedules will keep your tool in optimal working order.