Maintaining your outdoor equipment requires a thorough understanding of its various elements. A clear view of each part and its function ensures better repairs, replacements, and overall performance. Proper knowledge is crucial to keep machinery running efficiently and prevent potential issues from escalating.

In this guide, we’ll explore how to identify the critical elements of your machine and learn how they interact. From basic components to more specialized pieces, knowing what each part does and how to replace them when needed is essential for long-term durability.

Whether you are an experienced user or a newcomer, having access to a detailed reference can save time and effort. Accurate identification of worn-out or damaged parts can help you make informed decisions and carry out repairs with confidence.

Toro 518 ZE Parts Overview

Understanding the components of your outdoor machine is essential for proper maintenance and effective operation. Each individual element contributes to the overall performance, ensuring smooth functionality during use. Familiarity with the main sections of the equipment helps identify which parts are crucial for regular upkeep and which may need replacement over time.

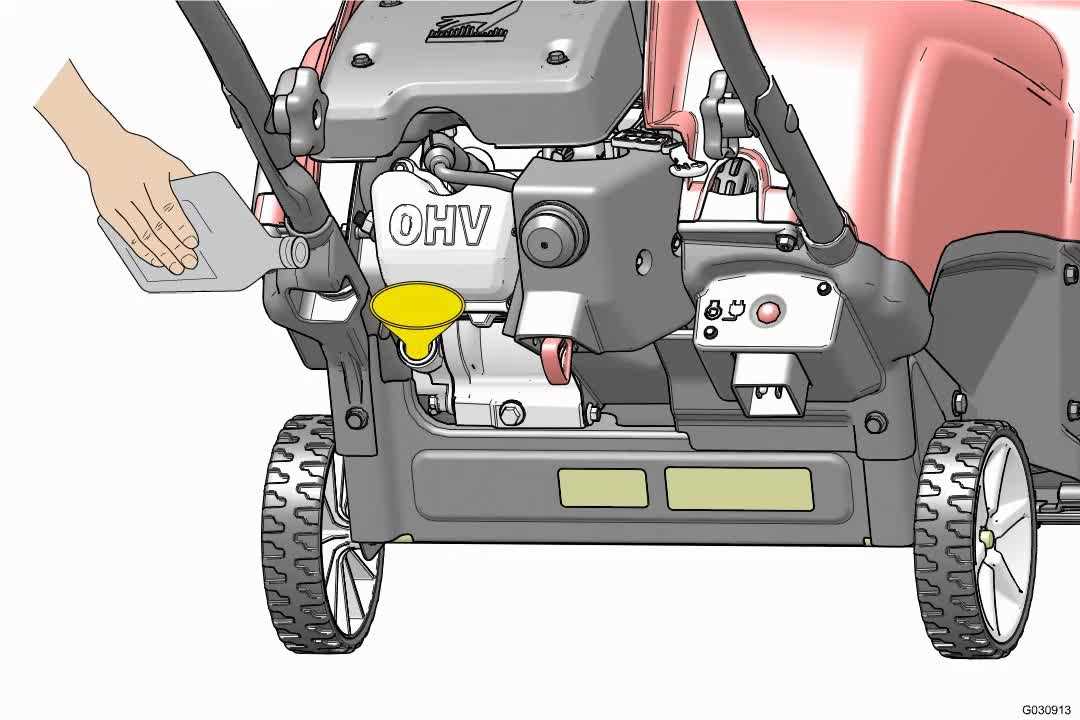

The machine is made up of several key segments, each playing a unique role. From the engine to the wheels, each part serves a specific function that enhances the performance of the entire unit. Being able to recognize these elements and their respective locations allows for quicker diagnostics and more efficient repairs.

Having a comprehensive understanding of these components not only aids in repairs but also helps prevent unnecessary breakdowns. Regular checks and knowledge of the individual parts ensure longevity and reduce the risk of more significant issues arising in the future.

How to Read the Toro 518 ZE Diagram

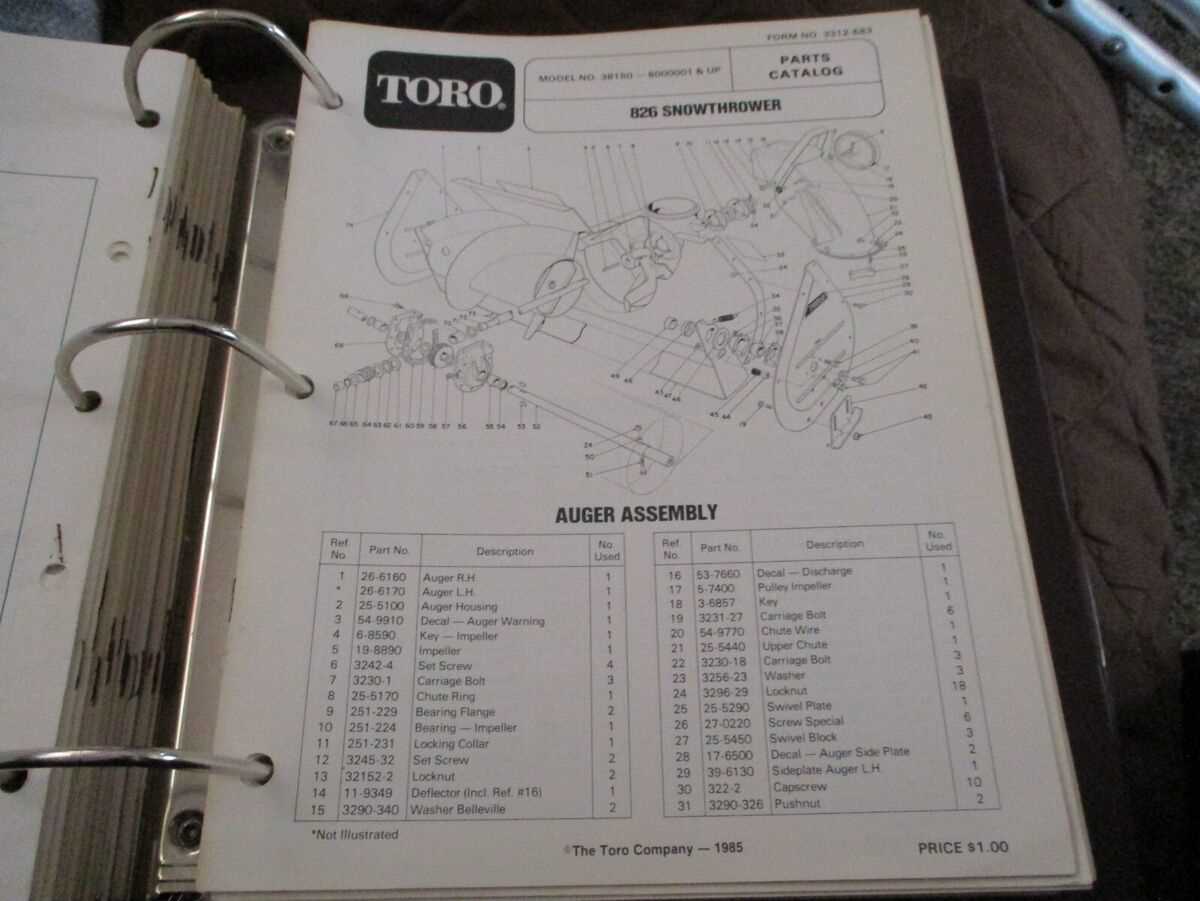

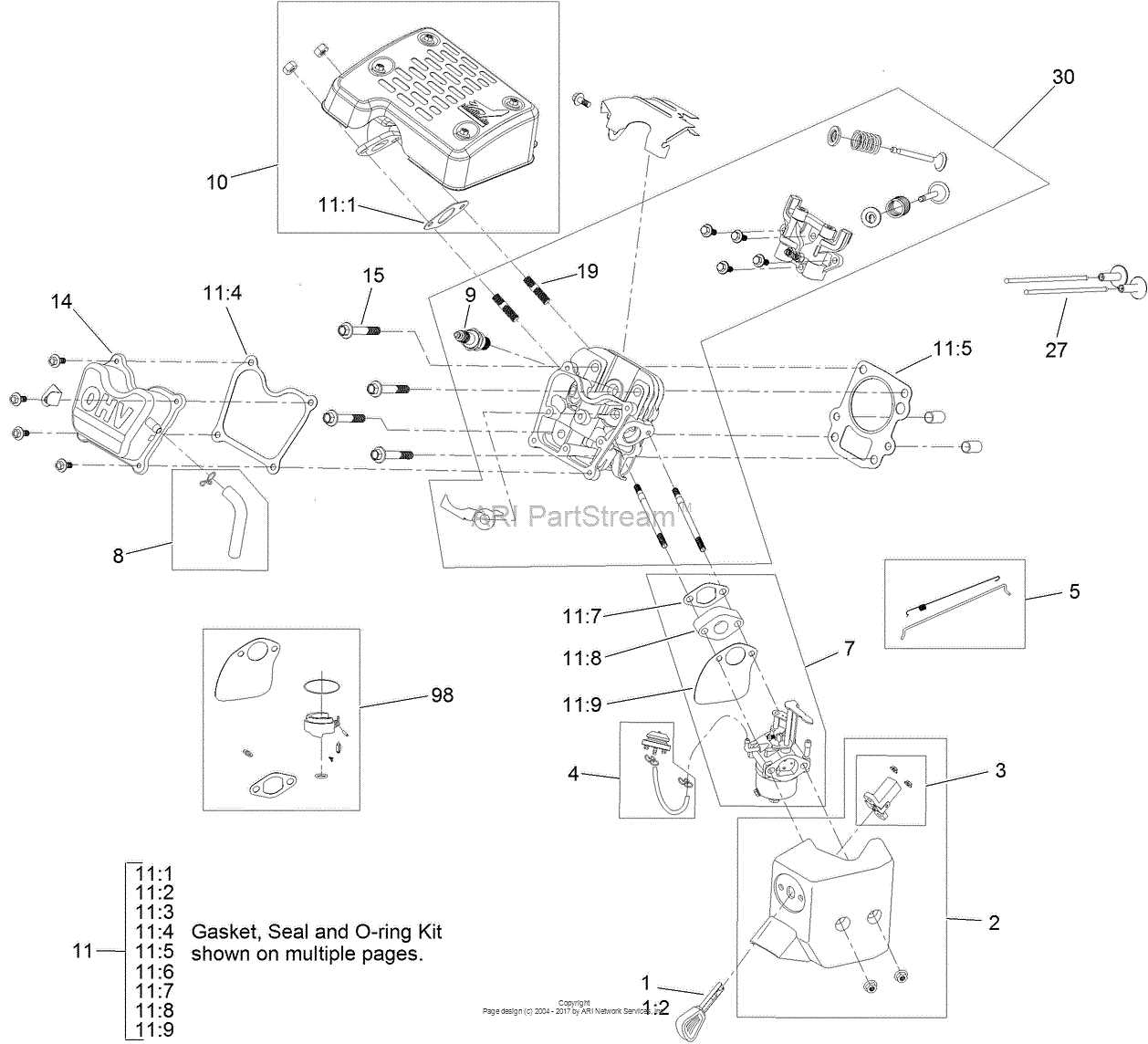

Interpreting a technical reference can be challenging at first, but understanding its structure is essential for identifying components and their relationships. The visual representation of your equipment’s layout provides a clear guide to help locate individual elements and determine their function. Knowing how to read such a schematic is crucial for performing accurate repairs and maintenance.

Begin by familiarizing yourself with the overall layout. Each section is typically labeled with numbers or letters, which correspond to specific components. Understanding these labels is the key to quickly pinpointing parts when you need to replace or inspect them. Pay attention to the connections between pieces, as this will help you understand how the machine operates as a whole.

In addition to labels, look for any symbols that may indicate the type of part or its specific function. Some diagrams also include a legend or key that explains these symbols in detail. Once you have a basic understanding of the layout and symbols, you will be able to efficiently navigate the schematic for troubleshooting or repairs.

Common Replacement Parts for Toro 518 ZE

Over time, certain elements of your outdoor equipment may wear out or become damaged, requiring replacement to maintain optimal performance. Identifying these parts early can help prevent more significant issues and extend the lifespan of the machine. Some components are more prone to wear than others, making them common candidates for replacement.

Engine belts are one of the most frequently replaced items, as they endure constant tension and friction during operation. Wheels and tires also tend to wear down due to regular use, and may need replacement if they become damaged or lose traction. Additionally, air filters often require periodic changing to ensure the engine runs smoothly and efficiently.

Other common replacements include spark plugs, which can degrade over time, and fuel filters, which help maintain the quality of the fuel reaching the engine. Knowing which components are most likely to need replacement can help you stay ahead of potential issues and ensure your equipment remains in top condition.