Maintaining your lawn care machinery is essential for ensuring its longevity and efficiency. Proper understanding of the internal components and how they work together can make repairs and maintenance tasks much easier. Whether you’re a seasoned gardener or a first-time user, having a clear grasp of how everything fits together will save time and reduce costly repairs.

In this guide, we will explore how to identify the main components of your lawn equipment, how to interpret the layout of these parts, and provide practical advice for regular upkeep. By the end, you’ll be better equipped to tackle minor repairs and ensure your machine runs smoothly for years to come.

Stay proactive with maintenance, and your equipment will perform at its best, delivering reliable results every time you use it. Understanding the mechanics behind it all can transform a simple chore into a straightforward task.

Understanding Kubota RCK60 Deck Components

When working with any lawn care machinery, it’s crucial to understand the individual elements that contribute to its overall functionality. Each component plays a significant role in ensuring smooth operation, and recognizing their positions and interconnections can make a big difference in the performance of your equipment. Whether you’re performing routine maintenance or troubleshooting an issue, a solid grasp of these essential parts helps you work more efficiently.

The main sections of your equipment include the cutting mechanism, drive system, and supporting structure. Each section is carefully designed to work in harmony with the others, making the entire system function as intended. Knowing where each element is located and how it interacts with the others can simplify repairs and keep your equipment running at peak performance.

Familiarizing yourself with these components ensures that you can easily spot issues before they become major problems, saving both time and money. Regular checks and a basic understanding of how everything fits together will allow you to address minor issues promptly and keep your equipment in top condition.

How to Read the Parts Diagram

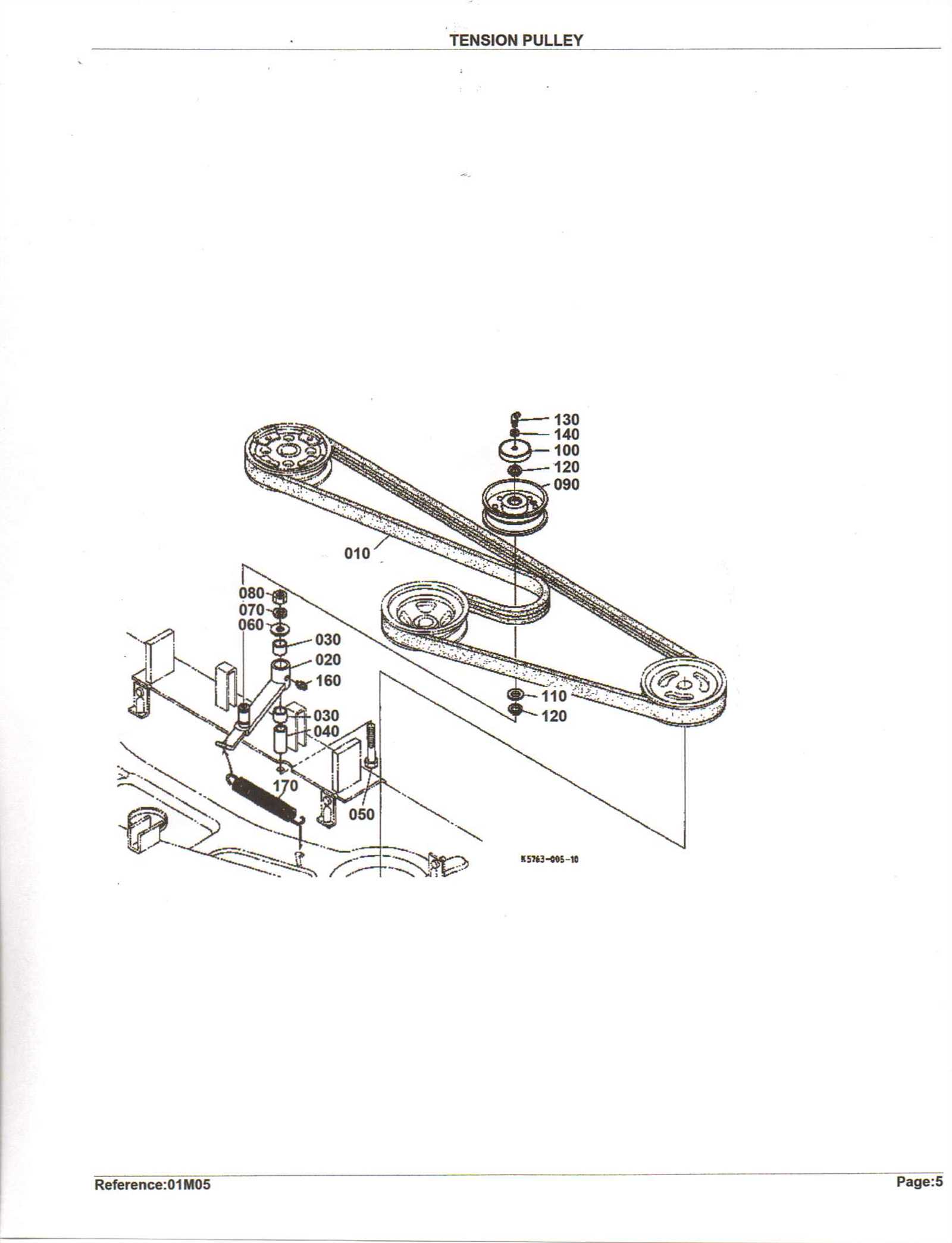

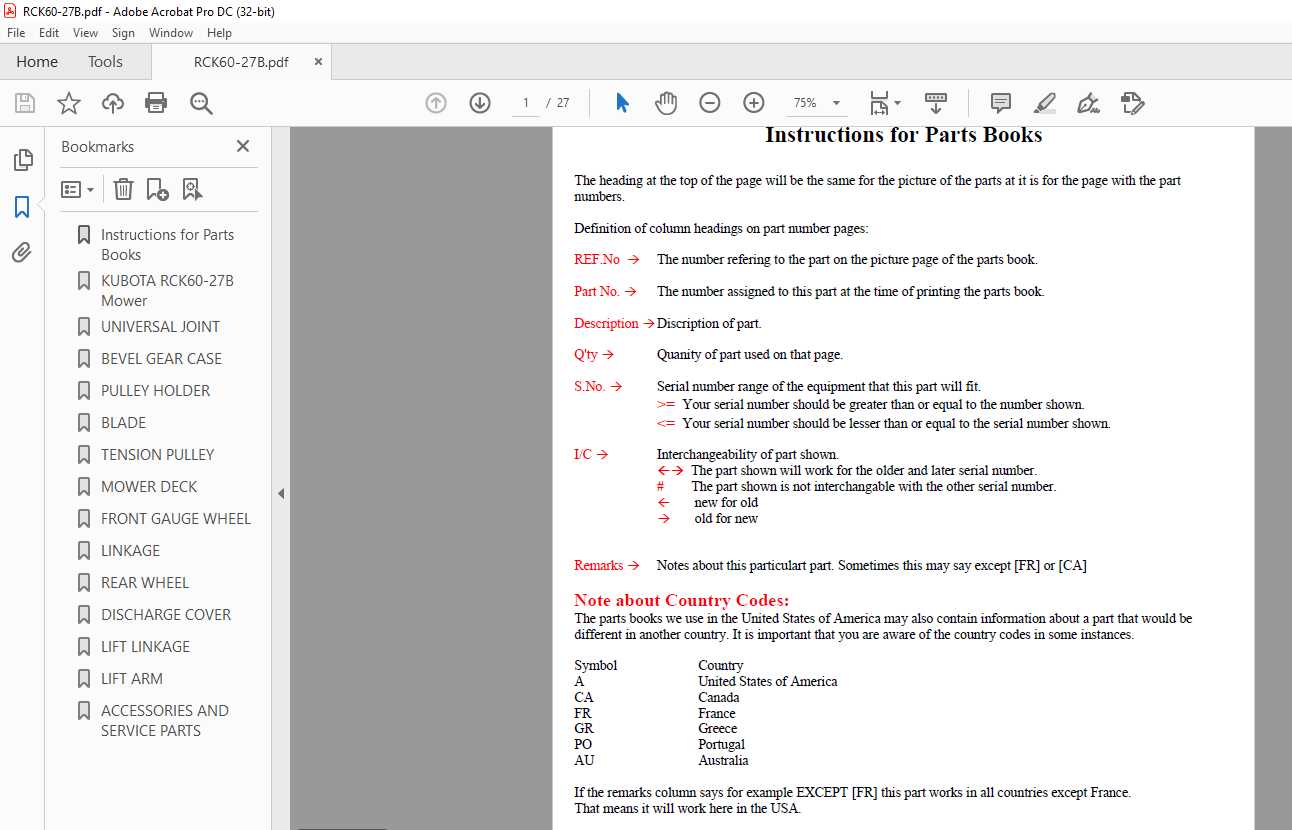

Understanding a visual representation of your equipment’s components is an essential skill for any user. These illustrations provide a detailed view of how each element fits together, helping you identify and locate parts quickly. Knowing how to interpret these images can significantly simplify repairs and maintenance, allowing you to address issues efficiently.

Identifying Key Components

The first step in interpreting any technical illustration is recognizing the primary sections. Each area of the image corresponds to specific parts, such as the cutting mechanism or the power drive. By learning to distinguish these, you can easily navigate through the diagram and pinpoint the component you’re working with. Most diagrams use clear labels and numbers to help you identify these sections with ease.

Understanding Part Numbers and Labels

Once you’ve located the components, the next step is understanding the labels or numbers associated with each part. These references are crucial when ordering replacements or finding more detailed specifications. Often, the numbers are linked to a parts list, which provides additional context about each element’s function and compatibility. Taking note of these identifiers ensures that you can acquire the correct replacements when necessary.

Common Maintenance Tips for Mower Deck

Proper upkeep of your lawn equipment ensures its longevity and optimal performance. Regular maintenance tasks help prevent common issues, reduce wear and tear, and keep everything functioning smoothly. By staying proactive with care, you can avoid costly repairs and maximize efficiency over time.

Cleaning and Inspection

One of the most important maintenance tasks is regularly cleaning your equipment to prevent buildup of grass clippings, dirt, and debris. This can help prevent clogs and ensure that all components work without obstruction. Additionally, during each cleaning, inspect key areas for wear and tear, such as the cutting blades, belts, and pulleys. Early detection of any issues allows you to address them before they become serious problems.

Lubrication and Tightening

Keeping moving parts properly lubricated reduces friction and prevents premature wear. Make sure to apply the appropriate lubricant to all moving components, including bearings, spindles, and drive systems. Additionally, periodically check all bolts, nuts, and screws to ensure they are tightly fastened, as loose parts can lead to performance issues or damage during operation.