Proper maintenance and repair of your boat’s propulsion system are essential to ensuring its longevity and optimal performance. Every element within the motor plays a specific role, and understanding how each part functions is key to effective care and troubleshooting. With the right knowledge, you can quickly diagnose issues and make informed decisions on repairs or replacements.

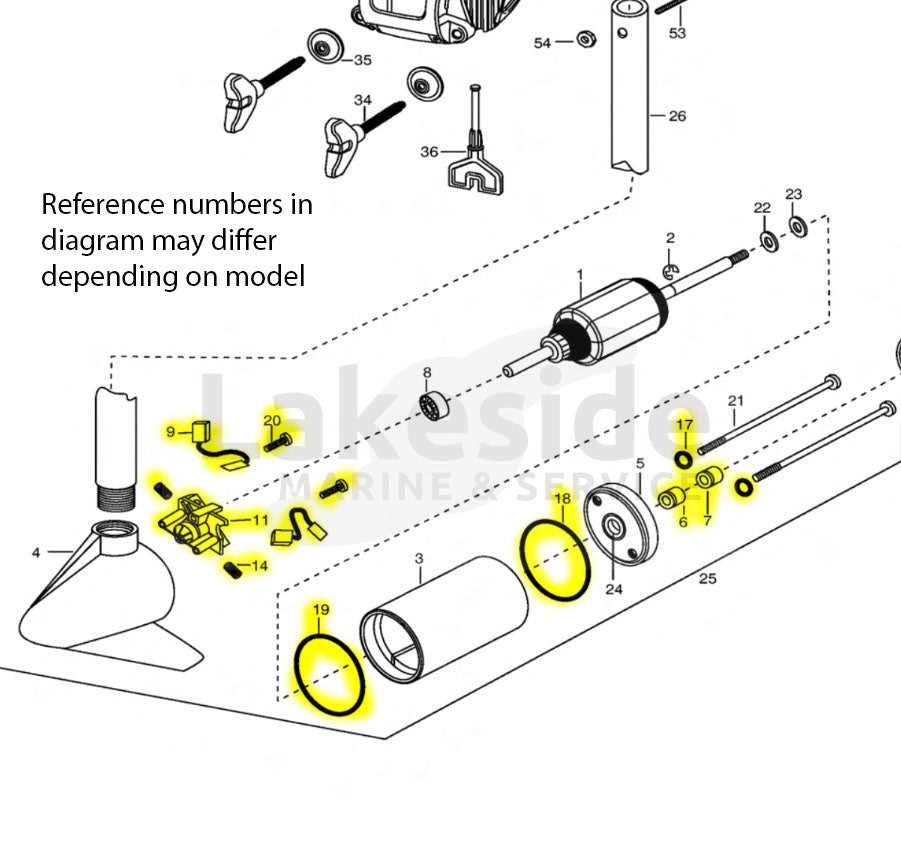

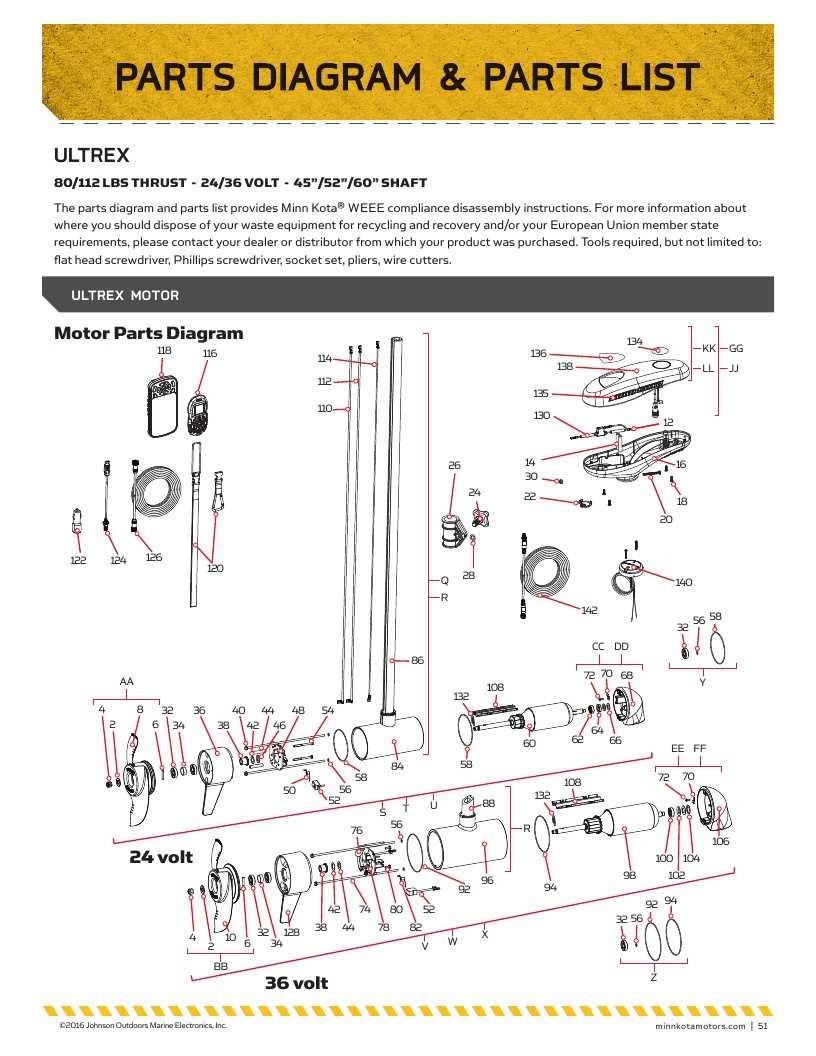

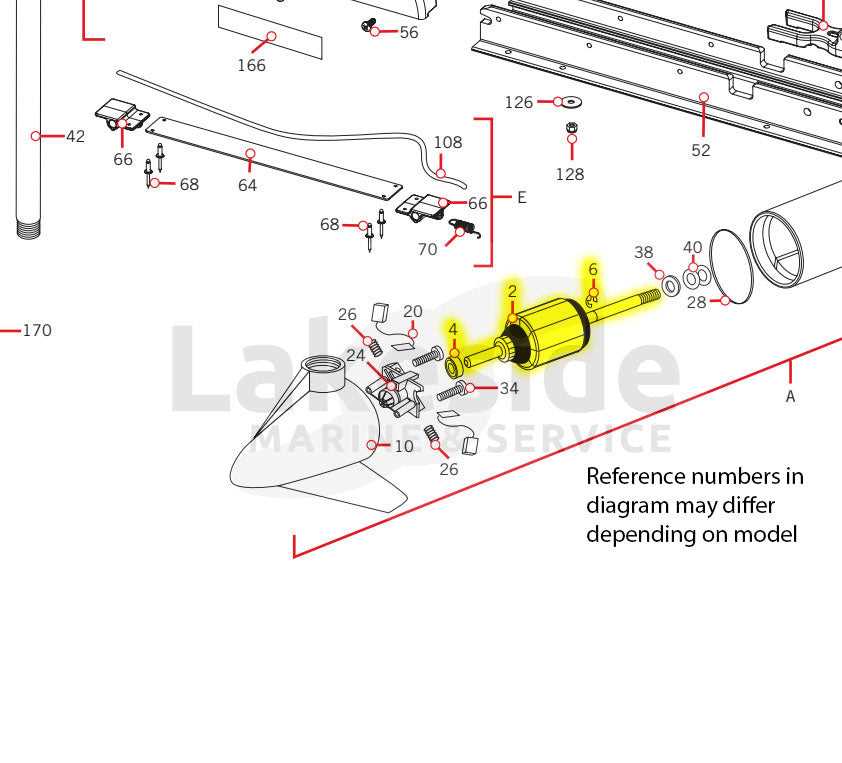

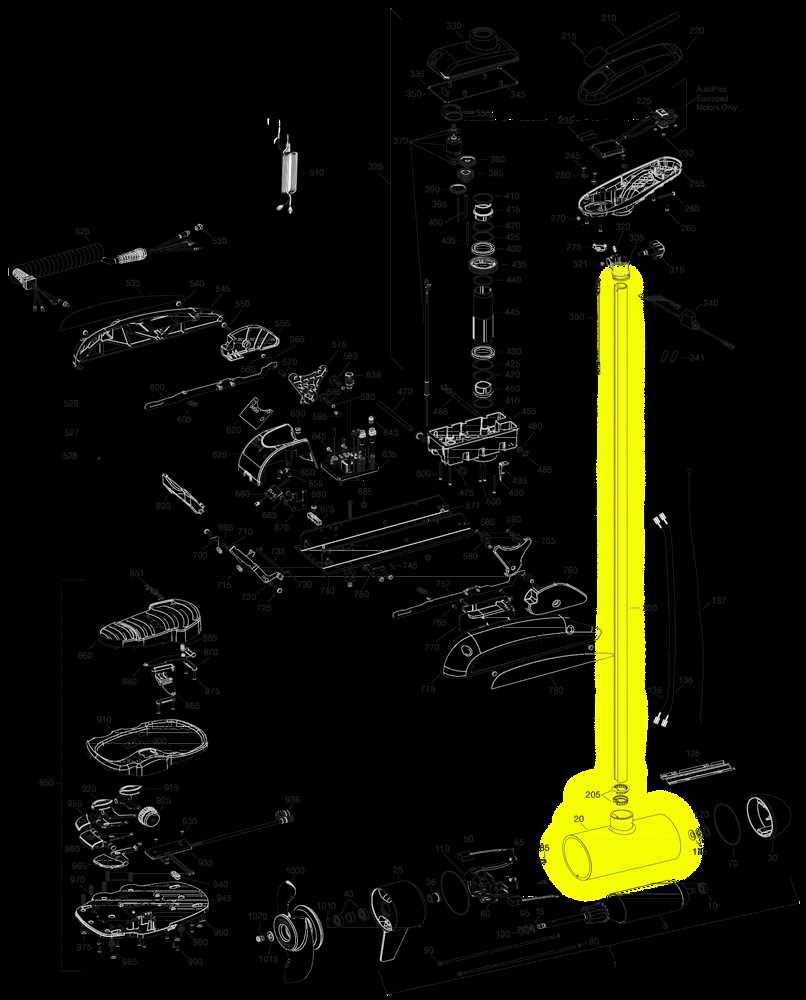

Familiarizing yourself with the structure and components of your motor helps prevent unnecessary damage, reduces the need for professional assistance, and extends the lifespan of the equipment. A clear visual guide is one of the most valuable tools you can have, enabling easy identification of each section.

Using a well-organized visual reference can simplify the process of identifying faulty parts and conducting repairs. Whether you are a seasoned professional or a beginner, a comprehensive guide will enhance your ability to maintain your equipment independently and effectively. This knowledge ensures you stay prepared for any situation, keeping your vessel running smoothly for years to come.

Exploring the Motor Components

When it comes to ensuring the efficient operation of your boat’s motor, it’s crucial to understand each of its individual elements. From the mechanical components to electrical systems, each part plays a role in keeping everything running smoothly. Familiarizing yourself with these components allows for quicker troubleshooting and more effective maintenance.

Key Elements to Recognize

There are several core sections in a motor that require attention and knowledge for optimal upkeep. Knowing their functions and locations will help you when performing repairs or replacements:

- Motor housing: Protects internal components from water and debris.

- Propeller: Provides the necessary thrust to propel the boat forward.

- Control module: Regulates speed and direction, ensuring smooth operation.

- Battery system: Supplies power for starting the motor and running electronics.

- Steering mechanism: Allows the operator to control the boat’s direction.

Understanding the Functionality

Each part works in harmony with the others, ensuring smooth and reliable performance. Here’s a closer look at how they contribute to the overall function:

- The motor housing is designed to protect internal mechanisms from the elements while providing easy access for maintenance.

- The propeller, often overlooked, is the heart of propulsion. Ensuring it is free from damage or debris is essential for maximum efficiency.

- The control system allows precise manipulation of speed and direction, which is vital for safe operation in different water conditions.

- The battery system powers the motor and electronics, ensuring that you have the necessary energy when you need it most.

- The steering mechanism provides precise control, ensuring that the vessel follows the desired course without difficulty.

By gaining a solid understanding of these components, you can ensure that your motor operates at peak performance and that any issues can be quickly identified and addressed.

Detailed Breakdown of Key Components

To effectively maintain and troubleshoot a boat’s propulsion system, it’s important to have an in-depth understanding of the critical elements involved. Each component contributes uniquely to the overall performance, and recognizing their individual functions helps streamline maintenance tasks. A detailed analysis of these components allows for better repair decisions and enhances the overall efficiency of your vessel.

Each section of the motor plays a pivotal role in its operation. The following breakdown highlights the most important components that you need to focus on when maintaining the system:

- Motor housing: Protects sensitive internal components from environmental elements, ensuring longevity and reliable performance.

- Propulsion system: Comprising the propeller and related mechanisms, this system directly impacts the boat’s speed and movement in water.

- Electrical unit: Responsible for providing power to the motor and various boat functions, including lights and other accessories.

- Control unit: Manages the speed and direction of the vessel, giving the operator complete control over the boat’s navigation.

- Steering system: Allows for precise adjustments to the boat’s direction, ensuring smooth and safe maneuverability.

Understanding these key components in detail not only helps with troubleshooting but also assists in identifying potential issues early, allowing you to address them before they affect performance. Proper knowledge can prevent unnecessary damage and enhance the overall durability of your motor system.

Understanding the Maintenance Process

Proper care and maintenance are crucial to extending the lifespan of any mechanical system, especially when it comes to marine equipment. Regular upkeep ensures that your boat operates efficiently and prevents costly repairs. Knowing the correct maintenance steps and the right time to perform them is key to keeping your motor running smoothly.

Routine maintenance is necessary to identify potential issues before they become significant problems. From cleaning to replacing worn-out components, each task contributes to the overall performance and safety of your vessel. Timely maintenance prevents breakdowns and improves the motor’s longevity, ensuring that you can rely on it whenever needed.

Understanding the maintenance process involves a clear approach to checking, cleaning, lubricating, and replacing various components. Keeping a maintenance schedule and following manufacturer recommendations will help you address issues proactively, ensuring smooth operation on the water.

How to Maintain and Replace Components

Maintaining and replacing components of your boat’s motor is a vital task to ensure long-lasting performance. Regular care can prevent small issues from becoming major failures and help you avoid costly repairs. Knowing when and how to replace specific elements is essential for keeping your equipment in top condition.

Routine Maintenance Tips

Proper maintenance includes tasks such as cleaning, inspecting, and lubricating key areas to prevent wear and tear. Regular checks help identify signs of damage early, allowing for timely intervention before a part completely fails. Here are a few tips for maintaining your motor:

- Inspect the motor housing for signs of cracks or water damage.

- Lubricate moving parts regularly to prevent rust and ensure smooth operation.

- Check the battery for corrosion or signs of wear, cleaning terminals as needed.

- Ensure that the control unit and electrical connections are secure and free of debris.

When to Replace Components

Some components will eventually need to be replaced due to wear. Recognizing the signs of damage or malfunction can help you decide when a part needs to be replaced. Look for the following indicators:

- Excessive noise or vibration during operation.

- Reduced performance or failure to power on.

- Visible cracks or damage to critical components like the propeller or steering mechanism.

- Loss of power or issues with speed control.

By following a regular maintenance schedule and addressing issues promptly, you can ensure that your motor remains in optimal working condition. Replacing faulty components at the right time will help prevent further damage and ensure your vessel operates reliably throughout its lifespan.

Maximizing Performance with Accurate Diagrams

Understanding the internal structure and layout of your boat’s motor is essential for maximizing its performance. A clear and precise visual reference can significantly improve your ability to identify issues quickly and perform repairs efficiently. When you can easily see how components interact and their exact placement, maintenance becomes much more effective and less time-consuming.

Using an accurate visual guide allows you to pinpoint specific components that may require attention, whether it’s for cleaning, replacement, or adjustment. This clarity ensures that no part is overlooked, and you can focus on areas that need the most care to maintain optimal functionality. By following a well-organized reference, you reduce the chances of making mistakes or missing crucial steps during maintenance.

Additionally, when troubleshooting problems, an accurate layout allows you to systematically check each area, helping you detect malfunctions before they cause more significant damage. Whether you’re a novice or experienced operator, having this resource on hand ensures that repairs and maintenance are performed correctly the first time, keeping your motor in excellent condition and extending its overall lifespan.