When it comes to maintaining outdoor machinery, understanding the structure and function of its individual components is essential for proper upkeep and repair. Identifying each part and how it contributes to the overall performance can save time and effort when dealing with issues that may arise during use. Having access to a clear visual reference allows you to pinpoint specific areas needing attention.

Knowing where each piece fits and how they interact with one another makes troubleshooting much easier. Whether you’re working on a simple fix or a more complex replacement, having a clear understanding of the layout and function of all key elements ensures you’re always prepared for maintenance tasks. This guide will provide you with the necessary insights to tackle such tasks with confidence and precision.

Understanding Swisher 60 Mower Parts

Maintaining outdoor equipment requires a solid understanding of how each component contributes to its overall function. From the cutting mechanism to the engine, each section plays a role in ensuring efficient performance. By familiarizing yourself with the various elements, you can identify and address potential issues more effectively, improving both the longevity and reliability of the machine.

Key Components and Their Functions

The key components of any lawn equipment include the motor, blade system, drive assembly, and control mechanisms. Each of these parts must work in harmony to achieve optimal results. The motor provides the power, while the blade system is responsible for cutting the grass. The drive assembly ensures smooth movement, and the control mechanisms allow the operator to manage speed and direction.

How to Identify and Replace Parts

Recognizing when a component is worn out or damaged is the first step in effective repair. Most equipment manufacturers offer guides to help owners identify each part and its function. If a replacement is necessary, it is crucial to choose the right part for the model to avoid any compatibility issues. Knowing how to locate and install the correct parts ensures the machine continues to operate smoothly after repairs.

How to Read a Swisher Parts Diagram

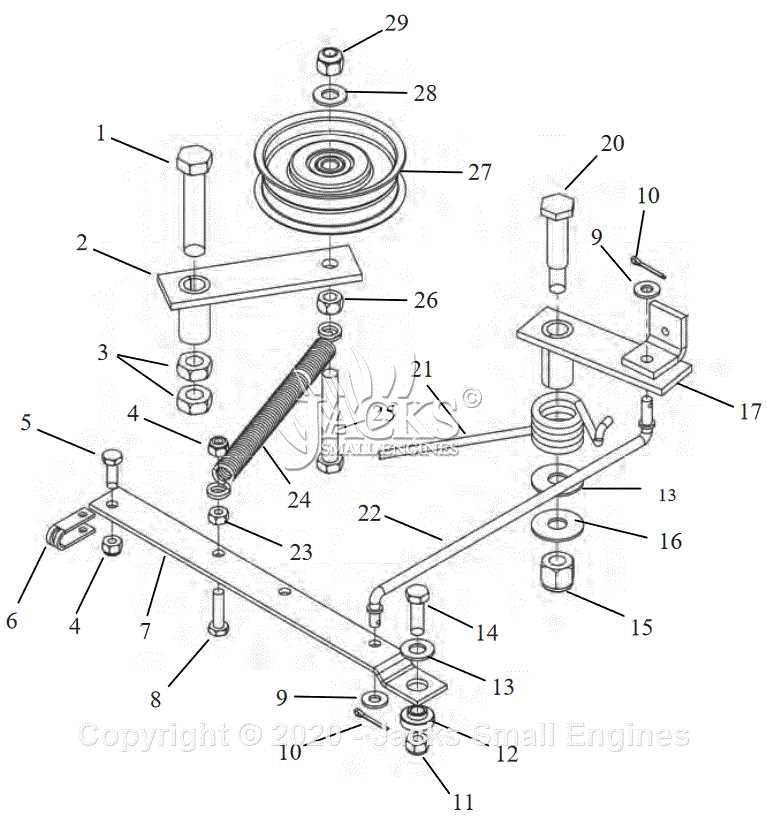

Understanding the layout of a machine’s components through a visual guide is crucial for efficient repairs and maintenance. These illustrations break down the machine’s structure, allowing you to see each piece and its connection to others. Knowing how to interpret these guides will enable you to identify parts quickly and accurately, ensuring smoother fixes and replacements.

Decoding the Symbols and Labels

Most visual guides feature clear symbols and labels to help users identify each part. The key to understanding these guides lies in recognizing what each symbol represents. Labels usually provide part numbers, which are vital when ordering replacements. Additionally, some diagrams include arrows and lines to show how parts connect, helping you understand the assembly and disassembly process.

Following the Sequence for Accurate Assembly

Many of these guides are structured in a way that shows the step-by-step sequence of part installation. It’s important to follow this order to ensure that everything fits together correctly. Each step typically includes a visual reference, allowing you to check your progress and confirm that all components are in place before proceeding.

Common Issues and Repair Tips for Swisher Mowers

Like any outdoor equipment, machinery designed for lawn maintenance can experience wear and tear over time. Understanding common issues and knowing how to address them quickly can prolong the lifespan of the machine and improve its performance. This section outlines typical problems and provides practical solutions to keep your equipment running smoothly.

Engine Performance Problems

If the engine is running rough or fails to start, the issue may lie in the fuel system, ignition components, or the air filter. Clogged fuel lines, dirty spark plugs, or a blocked air intake can lead to poor engine performance. Regularly cleaning or replacing these components can significantly improve functionality. Ensure that the fuel system is free of debris and that spark plugs are in good condition for smoother operation.

Blade and Cutting Mechanism Issues

Uneven cutting or excessive vibrations may indicate that the blades are dull, bent, or misaligned. Regular inspection and sharpening of the blades are necessary to maintain cutting efficiency. In some cases, replacing the blades or adjusting their alignment will help restore optimal performance. Always ensure that the blade system is securely fastened before use to prevent further damage.