Maintaining and repairing agricultural machinery requires a clear understanding of each element involved. Knowing the individual components of a machine is essential for proper upkeep and efficient operation. With the right knowledge, identifying and addressing any issue becomes more manageable, ensuring longevity and optimal performance of the equipment.

In this section, we will break down the critical components that make up a typical farm machine, offering insights into how each part functions and interacts with others. By mastering this knowledge, operators can confidently tackle troubleshooting tasks and identify necessary replacements, reducing downtime and improving productivity.

Understanding the structure of agricultural machines allows users to make informed decisions when faced with maintenance challenges. With a thorough understanding of these systems, even complex repairs become simpler and more efficient. Whether for routine checks or major repairs, familiarity with the machine’s makeup is a valuable asset for anyone involved in its care and operation.

Understanding the Frontier RC2060 Components

To properly maintain and operate any piece of machinery, it is essential to have a clear understanding of its individual components. This knowledge helps users identify how each part contributes to the overall functionality, enabling more effective troubleshooting and repairs. Recognizing how each element works together ensures smooth operation and minimizes unexpected breakdowns.

Key Elements of Agricultural Machinery

The primary structure of this equipment consists of various interconnected parts, each with a specific role in ensuring smooth performance. From drive systems to control mechanisms, each element works in harmony to complete tasks efficiently. Understanding how these components interact can simplify the process of diagnosing issues and replacing worn-out parts.

Benefits of Knowing Your Machine’s Layout

Familiarity with the internal layout and functions of the equipment allows users to recognize early signs of wear or malfunction. Being able to identify which components are essential for optimal performance helps with preventive maintenance. This proactive approach extends the machine’s lifespan, improves safety, and enhances productivity in the long run.

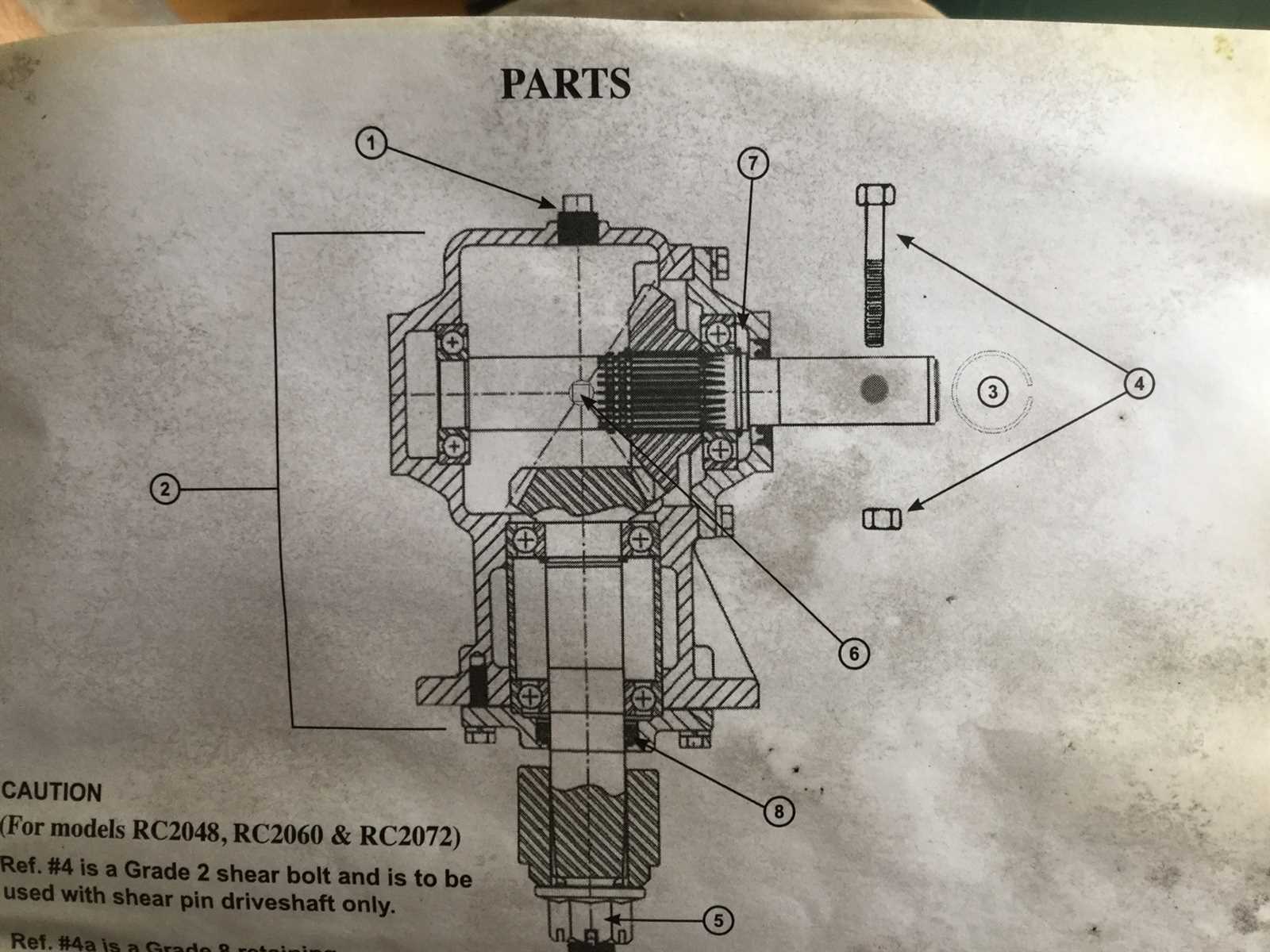

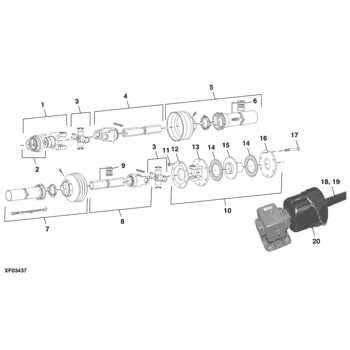

How to Read the Parts Diagram

Understanding technical illustrations is crucial for anyone performing maintenance on machinery. These visual guides provide detailed views of the equipment, showing how individual elements fit together. By learning to interpret these illustrations, users can easily identify components, understand their functions, and pinpoint where repairs or replacements may be needed.

Start with the overall layout. Begin by familiarizing yourself with the general structure of the machine as shown in the diagram. This initial overview helps you understand how the various parts are organized and connected. Pay attention to labels and numbers, which will guide you to specific sections and elements of the equipment.

Focus on the key components highlighted in the illustration. These are often the most critical parts that require regular checks or are more prone to wear. By focusing on these elements, you can prioritize maintenance tasks and ensure that the most important areas are kept in optimal condition.

Common Issues and Part Replacements

Like any machinery, farm equipment can experience wear and tear over time, leading to common issues that require attention. Recognizing these problems early on and understanding which components need to be replaced can help avoid costly repairs and minimize downtime. Proper maintenance and timely part replacements are essential for keeping the equipment running smoothly and efficiently.

Typical Problems Faced by Operators

One of the most frequent issues with farm machinery is the degradation of moving parts due to continuous operation. This often results in performance inconsistencies, such as reduced power or unexpected breakdowns. Components like bearings, belts, and hydraulic systems are particularly vulnerable to wear and should be checked regularly for signs of damage.

When to Replace Worn Components

Knowing when to replace specific components is key to preventing further damage. Parts that show visible signs of cracking, rust, or excessive wear should be replaced immediately to prevent them from affecting other systems. Regular inspections, following the recommended maintenance schedule, ensure that parts are replaced before they fail completely, keeping operations running without interruptions.