For any mechanical device, knowing its internal structure is essential for proper maintenance and repairs. Understanding how the different elements work together ensures optimal performance and longevity of the equipment. This section will help you gain a clearer view of the essential parts and their functions, guiding you through the process of identification and replacement when needed.

Every model has a unique set of components, each designed to fulfill a specific task. By familiarizing yourself with the layout and key pieces, you’ll be able to troubleshoot issues more efficiently and avoid unnecessary repairs. Having a clear understanding of these elements also simplifies the assembly and disassembly process.

Accurate identification of each component can save time and effort when fixing or upgrading your machine. Whether you’re performing routine maintenance or replacing worn-out pieces, this knowledge is vital for keeping everything running smoothly. Stay proactive and ensure that all parts are in working order to maximize performance.

Understanding Key Components

Each mechanical device consists of various essential elements that work in unison to perform specific tasks. Knowing how these parts interact is crucial for proper operation and troubleshooting. Understanding the main components helps in recognizing potential issues before they become major problems, ensuring the equipment functions at its best.

The internal structure includes various units that serve distinct purposes. Some parts are responsible for powering the machine, while others handle the movement or control functions. Being familiar with each piece allows for more effective maintenance, repairs, and part replacement when necessary. Recognizing the function of each element can save time and prevent unnecessary complications.

In addition to functionality, knowing the components helps in identifying wear and tear. Regular inspection of each part is crucial for extending the lifespan of the device. With proper knowledge of the essential pieces, maintaining the equipment becomes more manageable and less time-consuming.

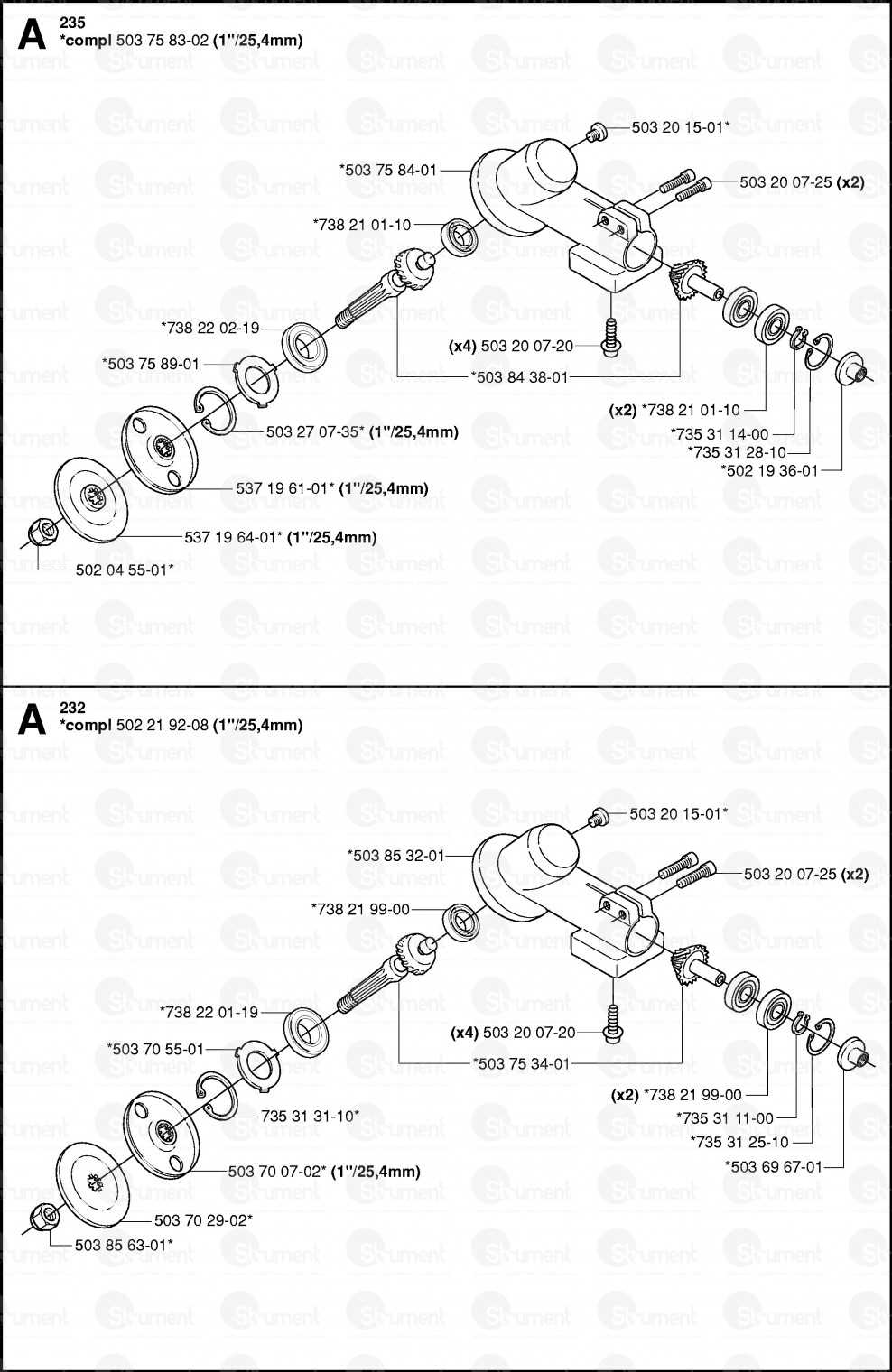

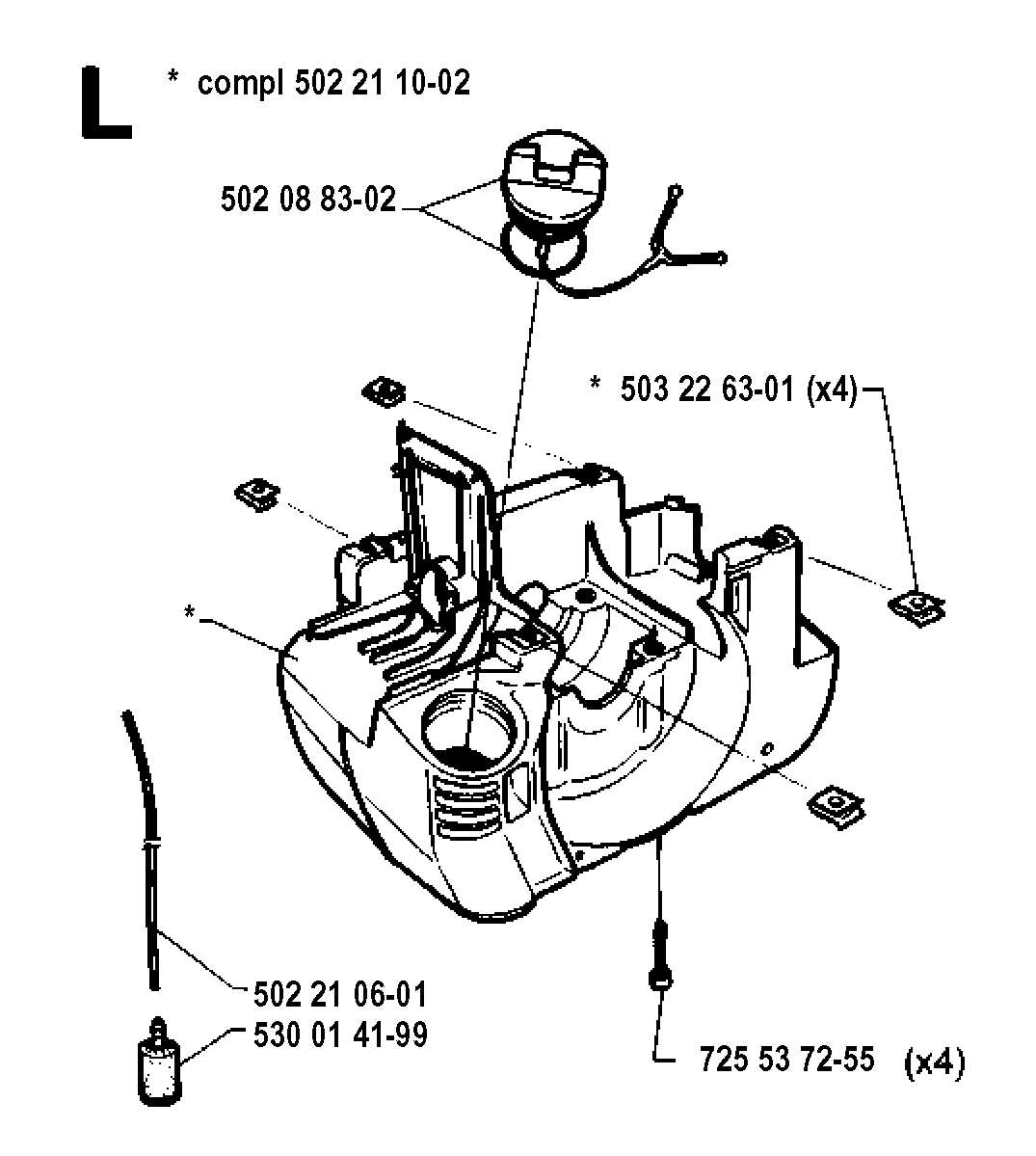

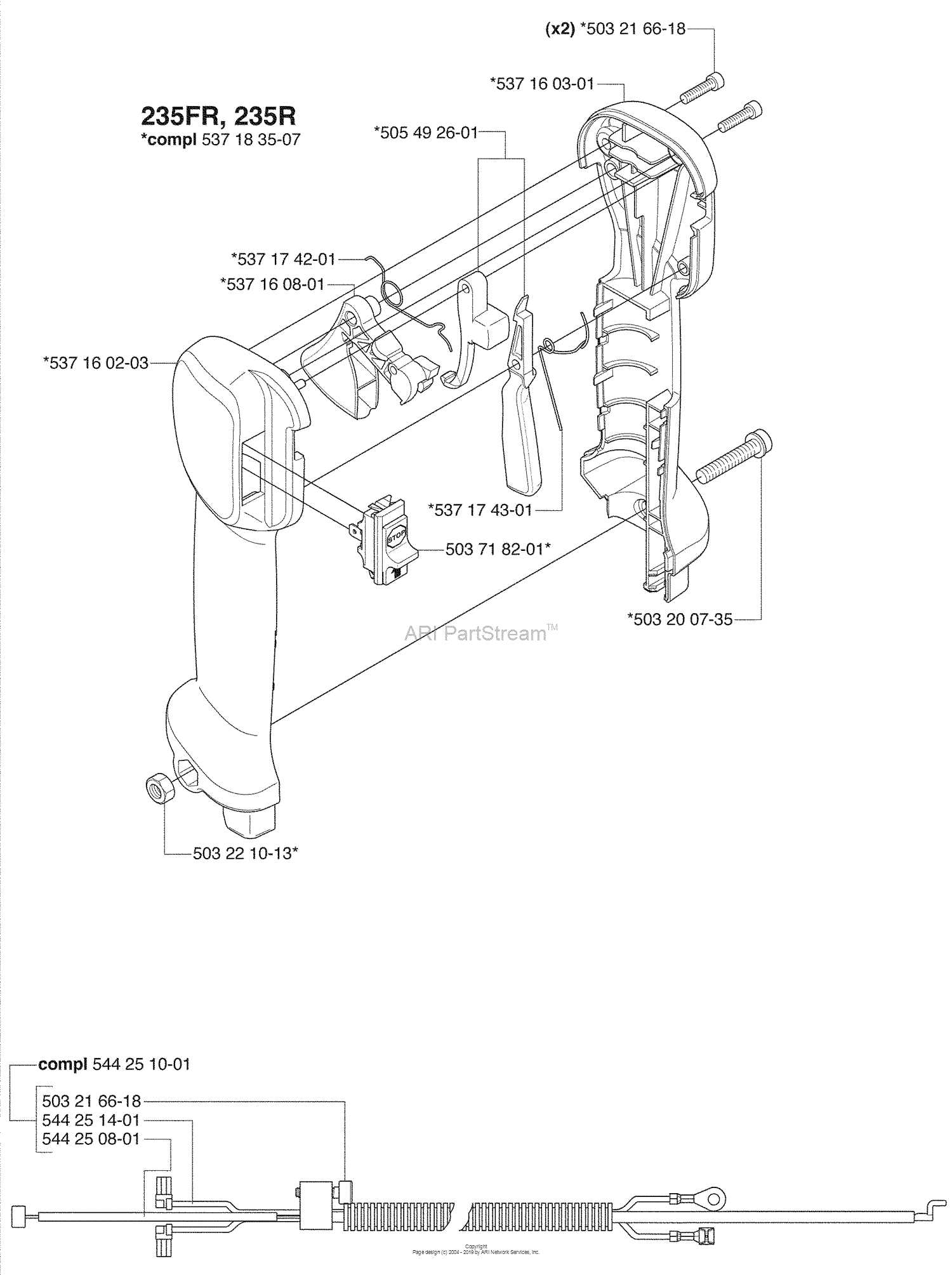

How to Read the Breakdown Illustration

Understanding the layout of a mechanical device is essential for anyone looking to perform repairs or maintenance. The breakdown illustration provides a visual guide that highlights the different components and their placement within the system. Learning how to read this guide enables you to identify parts more effectively, ensuring that you can replace or repair them with ease.

Identifying Key Elements

At first glance, the illustration may seem complex, but it is structured to make it easier to follow. The components are usually numbered or labeled, allowing you to quickly match each part with its corresponding function. Pay attention to the symbols or markings next to each part to gain a better understanding of their roles within the machine.

Locating and Replacing Components

Once you familiarize yourself with the layout, you can pinpoint the exact part that needs attention. This visual aid helps in determining which components are removable and how to access them. With clear identification, you can perform the necessary steps for replacement or adjustment, reducing the risk of damaging other parts during the process. Be sure to follow the illustrated sequence to ensure proper reassembly after maintenance.

Common Replacement Components

When maintaining any mechanical device, certain elements are more likely to experience wear and tear over time. Regularly replacing these components is crucial for keeping the equipment running smoothly. Identifying the most commonly replaced parts helps you stay ahead of potential issues, ensuring your machine operates efficiently for longer periods.

Among the frequently replaced components are those that handle movement, power transmission, and the control mechanisms. These parts are subjected to constant stress and can wear out faster than others. For example, parts related to the engine or drive system may need to be replaced after extended use. Regular inspection of these areas can help detect early signs of damage.

Other components, such as seals, filters, and belts, often require replacement to maintain optimal performance. Keep an eye on these wear-prone elements and replace them promptly to avoid more costly repairs down the road. Being proactive with these common replacements ensures your device remains functional and effective in its tasks.