Boat lift systems are essential for maintaining boats safely above water when not in use. To ensure smooth operation and effective maintenance, it is important to understand the core elements that make up these systems. Each component plays a vital role in the overall functionality, helping to prevent wear and tear while supporting the boat efficiently.

By familiarizing yourself with the structure and organization of these systems, you can easily troubleshoot, repair, or upgrade specific sections. Knowledge of the different mechanisms involved can save time and money, improving the longevity and performance of the entire setup.

Proper understanding of each part and how it interacts with others can also enhance safety during use. When familiar with the system’s design, users are better equipped to identify potential issues before they become serious problems.

Understanding the Key Components

Every boat lifting system consists of several interconnected elements designed to support, raise, and lower the vessel efficiently. These components must work together seamlessly to ensure smooth operation, long-term durability, and safety during use. A deep understanding of each element helps in maintaining, troubleshooting, and upgrading the system as needed.

Structural Components

The framework of a boat lift is typically made from durable materials that withstand environmental elements. The structure ensures that all other components are securely positioned and can handle the weight of the boat. It includes support beams, lifting arms, and the platform that holds the vessel when elevated. The integrity of these structural parts is crucial for overall safety.

Mechanical and Hydraulic Systems

Many boat lift systems rely on mechanical or hydraulic mechanisms to raise and lower the platform. These systems use motors, pulleys, and pistons to generate the necessary force. Understanding how these components work together enables operators to troubleshoot potential issues, such as failure to lift or uneven movement, that could arise due to malfunctioning parts.

Key Components in Boat Lifting Systems

Boat lifting systems consist of several essential elements that ensure safe and efficient operation. These components work together to support, lift, and lower boats with precision and ease. Understanding the function of each piece is vital for maintaining the system and ensuring its longevity.

- Frame – The main structure that supports all other components, ensuring the system’s stability and capacity to handle the weight of the boat.

- Lift Mechanism – The core system responsible for raising and lowering the platform, often involving hydraulic or mechanical forces.

- Pulleys and Cables – These components guide the movement of the lifting platform, allowing it to be controlled with accuracy.

- Motor or Pump – The power source that drives the lift mechanism, whether electric or hydraulic, providing the force required for smooth operation.

- Platform – The surface that holds the boat during lifting and lowering, providing secure support when the boat is above the waterline.

Each of these elements plays a crucial role in ensuring the system operates effectively and safely. Regular inspection and maintenance are necessary to keep these components in optimal working condition.

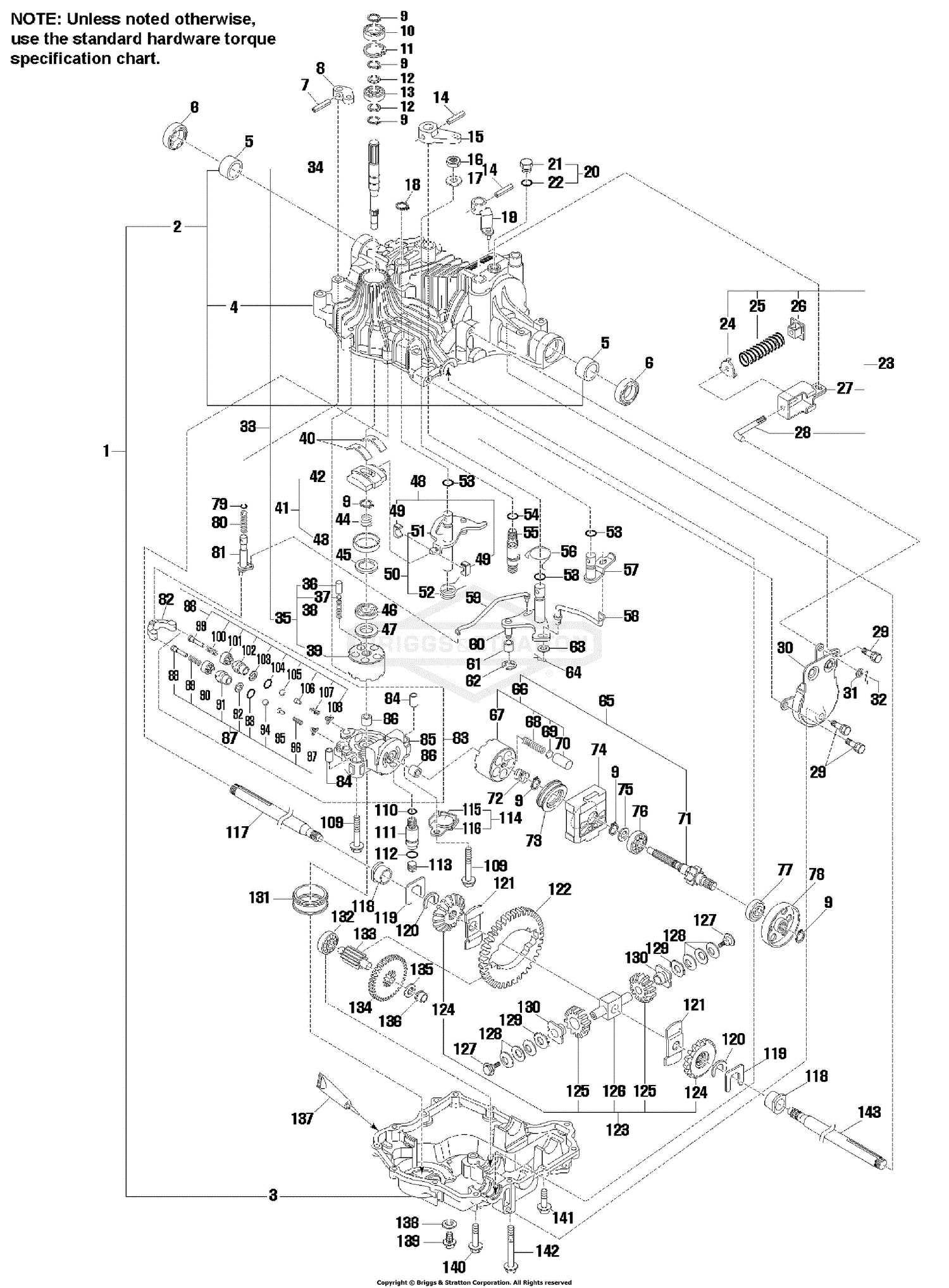

How to Read a Boat Lift Schematic

Understanding a schematic for a boat lift system is essential for effective troubleshooting and maintenance. These detailed illustrations provide a visual representation of the system’s components and how they connect and interact with each other. By learning how to interpret these drawings, you can identify key parts and their functions, which is crucial for proper operation.

Start with the Overview – Typically, a schematic will begin with a general overview, showing the entire system layout. This provides context for understanding the connections between different elements, such as the frame, motor, and lift components. Recognizing the overall structure helps you navigate more complex sections later in the schematic.

Follow the Lines and Labels – Pay close attention to the lines that connect different parts. These lines represent the flow of power, fluid, or mechanical movement. Often, the lines are labeled with important information such as voltage, pressure, or mechanical force. Understanding these labels will allow you to trace the path of energy or movement throughout the system.

Understand the Symbols – Schematics use standardized symbols to represent different mechanical and electrical components. Familiarizing yourself with these symbols is key to quickly identifying the parts involved. For example, a circle might represent a motor, while a rectangle could indicate a pump. Knowing what each symbol stands for will make interpreting the diagram more straightforward.