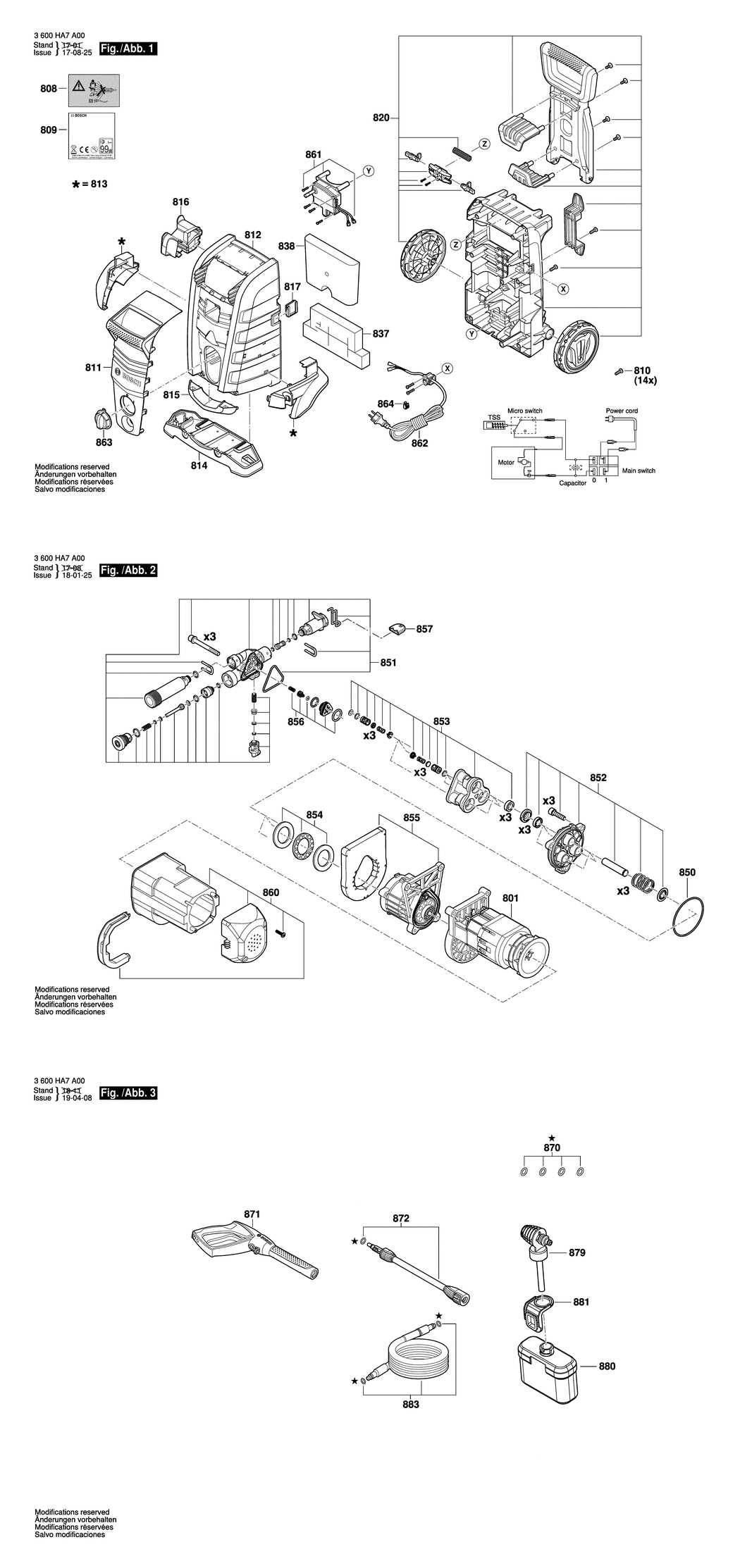

When it comes to maintaining a water heating system, understanding its internal structure is crucial for proper functionality. Identifying each element allows users to troubleshoot, replace faulty parts, and ensure optimal performance. Whether you’re a technician or a homeowner, having a clear understanding of these components can significantly ease the repair and maintenance process.

In-depth knowledge of the system’s components helps in diagnosing problems quickly. Recognizing how each part fits together is essential for any repair work. Over time, you may notice issues such as inefficiency or malfunctions, which are often linked to specific components within the unit.

To assist with repairs and upkeep, having a clear visual representation of the system’s structure can be invaluable. This approach makes it easier to identify what needs attention and how to fix it effectively. Whether you’re replacing worn-out elements or performing routine checks, a detailed guide can be your best tool.

Understanding Bosch Aquastar 125B Components

To fully grasp how a water heating system works, it’s important to familiarize yourself with the various elements that make up the unit. Each component plays a unique role in ensuring the proper functioning and efficiency of the system. Recognizing how these pieces interact with one another can help diagnose issues, perform repairs, and maintain the equipment in peak condition.

Key components within the unit include the heating mechanism, water flow controls, and safety features, each designed to work together seamlessly. Understanding the function of these components allows users to quickly identify when something is not operating as expected and take the necessary steps to resolve the issue.

When dealing with repairs or replacements, knowing the internal layout is crucial. Whether you’re replacing a malfunctioning part or conducting routine maintenance, understanding the components will make the process more straightforward. This knowledge also helps to avoid common mistakes that may arise from an incomplete understanding of the system’s structure.

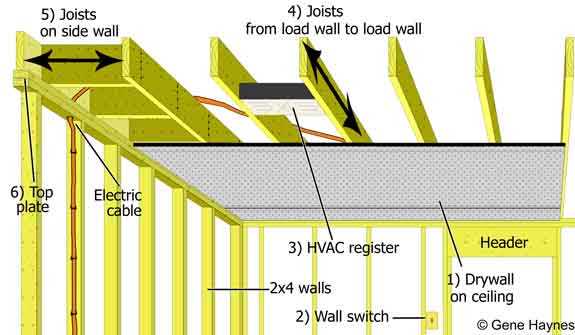

How to Read the Parts Diagram

Understanding how to interpret the internal layout of a heating system is an essential skill for anyone performing repairs or maintenance. A visual representation of the unit’s structure can simplify the process of identifying components, making it easier to locate specific parts and understand their functions. This guide will help you navigate these illustrations with ease, ensuring that you can make informed decisions during the troubleshooting process.

When looking at the layout, start by identifying the major components and their connections. Each part will typically be labeled with its name and corresponding function, which allows you to quickly match it to the issue you’re addressing. The diagram should also provide an overview of how the elements interact within the system, helping you understand their roles more clearly.

It’s also important to familiarize yourself with the various symbols and numbering systems used in these representations. Manufacturers often use specific conventions to indicate different types of connections, such as electrical wiring or water flow. By paying attention to these details, you can avoid confusion and ensure that you’re focusing on the right areas when performing repairs or replacing components.

Common Issues with Bosch Aquastar 125B Parts

Heating systems, like any complex appliance, may face a variety of issues over time. Understanding the common malfunctions of individual components can help you pinpoint problems quickly and take the right steps to resolve them. Familiarity with typical failures makes it easier to maintain the system and avoid unnecessary repairs.

One frequent issue is the buildup of mineral deposits in key areas, particularly around heating elements. This can reduce efficiency and lead to overheating or erratic performance. Another common problem is related to water flow. Blockages or leaks in the system can cause reduced water pressure or even prevent the unit from functioning altogether. Regular inspection can prevent these issues from escalating.

Electrical faults, such as worn-out connections or faulty sensors, are also common. These issues can lead to incorrect readings or a complete failure of the unit. Being aware of these typical failures helps in troubleshooting and allows for faster, more accurate repairs, ensuring the system continues to operate smoothly.