Having a clear understanding of the components of your tool is essential for efficient maintenance and troubleshooting. Knowing how each piece functions allows you to make informed decisions when repairing or replacing parts, ensuring your equipment stays in top condition for years. Whether you’re a professional or a hobbyist, being familiar with the inner structure can save both time and money.

In this guide, we will explore the essential elements that make up your tool, offering insight into their functions and how they interact with each other. A visual reference can be invaluable when working on repairs, helping you identify the specific parts you need to address any issue that arises. The goal is to simplify the repair process, making it more accessible and less daunting for users at all skill levels.

By understanding the layout and function of each component, you’ll be better equipped to handle any challenges and prolong the life of your equipment. This knowledge empowers you to take control of your tool’s maintenance and confidently make repairs when necessary.

Understanding the Tool’s Components

Each tool is made up of several key components that work together to ensure optimal performance. Recognizing these individual elements and their roles can greatly enhance your understanding of how the equipment functions. When you are familiar with the structure, it becomes easier to maintain and troubleshoot any issues that may arise.

In this section, we focus on breaking down the crucial components of the machine, from the engine to the various mechanical parts. By identifying how each element contributes to the tool’s overall function, you can gain a clearer perspective on how to care for and repair your equipment effectively. Knowing the purpose of each piece will allow you to tackle maintenance tasks with confidence.

Understanding these components not only aids in repairs but also helps you optimize the tool’s performance over time. When each part is in good working order, the entire system operates smoothly, minimizing wear and tear and extending the tool’s lifespan.

How to Read the Parts Diagram

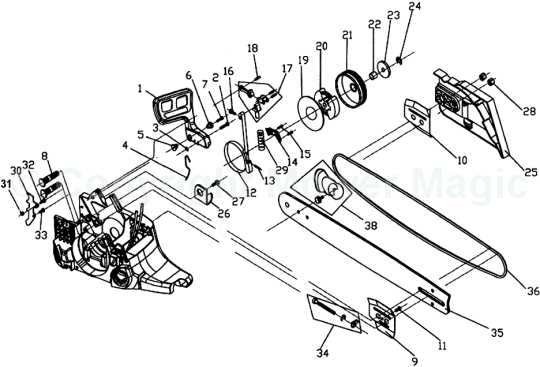

Understanding a visual guide to your tool’s components can make the process of identification and repair much easier. A well-organized reference chart provides a detailed layout of the various elements, highlighting their locations and relationships within the system. Knowing how to interpret these visuals allows you to quickly pinpoint the parts you need to address any issues.

When reading this reference guide, it’s important to familiarize yourself with the symbols, numbers, and labels used. Each part is typically marked with a unique identifier, making it easier to locate and replace. Pay close attention to the connections between different components to understand how they interact within the overall system. This will help you make more informed decisions when performing repairs or replacements.

By mastering the process of reading these visual tools, you’ll be able to navigate the complexities of maintenance with ease. Whether you’re fixing a malfunction or simply performing routine upkeep, a clear understanding of the layout is key to ensuring everything functions as it should.

Common Tool Repair Components

When maintaining or repairing your equipment, there are several key components that are frequently replaced due to wear or damage. Identifying which parts commonly need attention can help you prepare and ensure that your tool continues to function smoothly. These components often include engine elements, fuel systems, and mechanical parts that experience regular stress during use.

Commonly replaced items include the air filter, spark plug, and fuel lines. These components can become clogged, dirty, or worn over time, which can affect the tool’s performance. Additionally, wear and tear on the chain and guide bar is common, as they come into direct contact with materials during operation. Being familiar with these frequently replaced parts can make your repair tasks more efficient and reduce downtime.

By knowing which components tend to wear out most often, you can proactively replace them before they cause major issues. This approach helps in keeping your equipment running at peak efficiency and avoiding larger, costlier repairs down the line.