For anyone maintaining or repairing high-end refrigeration systems, knowing the internal components and their arrangement is essential. This knowledge not only helps in identifying issues quickly but also in ensuring proper functionality after replacements or repairs. The proper use of schematics can significantly reduce troubleshooting time and effort.

In this guide, we will explore the visual representation of various system elements, providing a clearer understanding of how each component fits into the whole. By recognizing each part’s location and function, users can make more informed decisions regarding repairs and replacements.

Familiarizing yourself with these layouts can save both time and money. Whether you’re a professional technician or a dedicated homeowner, having access to an accurate guide can greatly simplify your maintenance tasks. It also allows for more effective communication when seeking professional help or purchasing replacement parts.

Understanding Sub Zero 632 Parts

When dealing with high-quality refrigeration equipment, it’s crucial to understand the essential components that work together to ensure optimal performance. Every element inside the system plays a specific role, contributing to the unit’s efficiency and longevity. Gaining insight into each individual part’s function allows for better maintenance and more effective troubleshooting when issues arise.

Key Components and Their Functions

These machines typically consist of several major components, such as the cooling unit, seals, fans, and thermostats. Each part has a unique function that ensures the appliance maintains the correct temperature and operates efficiently. For example, cooling elements control temperature regulation, while seals maintain energy efficiency by preventing air leakage.

Maintenance and Troubleshooting

Familiarity with the internal layout can help pinpoint malfunctioning parts, allowing for more targeted repairs. Identifying worn-out components, such as faulty seals or damaged fans, is a vital part of maintaining the system’s longevity. Regular maintenance, combined with knowledge of the unit’s layout, can prevent minor issues from turning into major problems.

How to Read the Parts Diagram

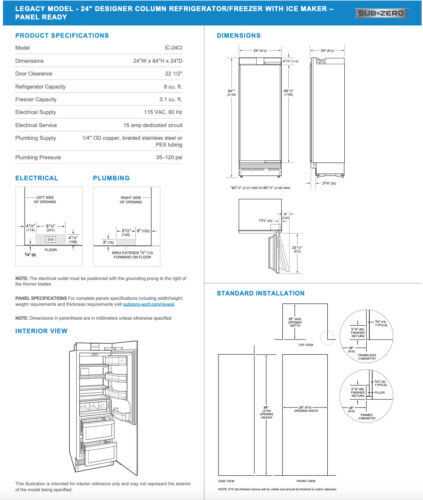

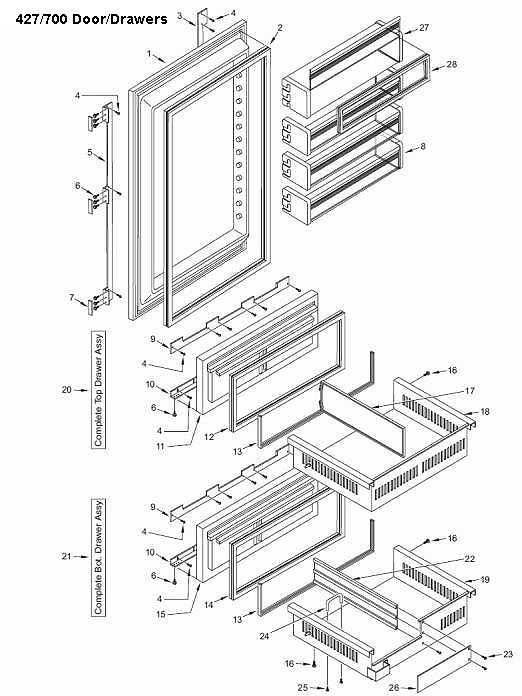

Understanding how to interpret the visual schematics of your refrigeration system is essential for efficient maintenance and repair. These visual representations show the location and connection of each component within the system, helping you identify the specific parts that may need attention. A well-understood layout allows for quicker troubleshooting and more informed decision-making when it comes to replacements or repairs.

Recognizing Symbols and Labels

The schematics often include various symbols and labels that represent different components. Each symbol corresponds to a specific part of the system, whether it’s a compressor, fan, or valve. Labels help clarify the function of each part, while numbers or letters might be used to reference particular components within the diagram.

Locating and Identifying Parts

Once you’re familiar with the symbols, the next step is to understand the layout of components within the system. These diagrams are typically organized to reflect the actual arrangement of parts inside the unit. Understanding the positioning is key to locating faulty components quickly. By following the flow of the diagram, you can identify where each part fits into the overall system and pinpoint areas that need attention.

Common Issues and Replacement Parts

High-end refrigeration units, while durable and reliable, may encounter occasional issues that require attention. These problems can range from minor glitches to more significant malfunctions, but understanding common failures and knowing which components need replacement can make the repair process smoother and quicker. Regular maintenance and awareness of typical faults are essential to extend the lifespan of your appliance.

One of the most frequent issues is the failure of cooling elements, which can lead to temperature irregularities. Another common problem is worn-out seals, which may cause energy loss or reduced efficiency. Fans, compressors, and thermostats are also prone to wear and may need replacing after years of use. Knowing which parts are most susceptible to failure allows for more proactive maintenance and quicker identification of problems when they arise.

When replacing a faulty component, it’s important to choose high-quality replacements to ensure optimal performance. It’s recommended to refer to the system layout to pinpoint the exact part number and its specifications. This ensures compatibility and avoids the risk of installing incorrect or subpar replacements.