Understanding the inner workings of a vehicle’s core is essential for grasping its performance and efficiency. In this section, we dive into the various elements that make up a modern Volkswagen power unit, offering a clear view of how each component functions together to ensure optimal operation.

Identifying the critical elements that influence overall performance allows enthusiasts and technicians alike to gain deeper insights into how small modifications or upgrades can impact vehicle functionality. The layout of these systems plays a crucial role in maintaining smooth interaction between them, directly affecting speed, fuel economy, and durability.

We will cover the arrangement and function of each key unit, helping you understand how these interconnected elements drive a Volkswagen vehicle’s overall efficiency. Whether you’re a car enthusiast or a professional mechanic, this exploration provides essential knowledge for anyone working with these systems.

Understanding Key Components of VW Power Unit

Every vehicle’s heart relies on a combination of systems working in harmony to ensure its proper functioning. In this section, we explore the core elements that contribute to the efficiency and performance of a Volkswagen power unit. These components, though diverse in function, work together seamlessly to generate the necessary force for motion and operation.

Essential Elements for Performance

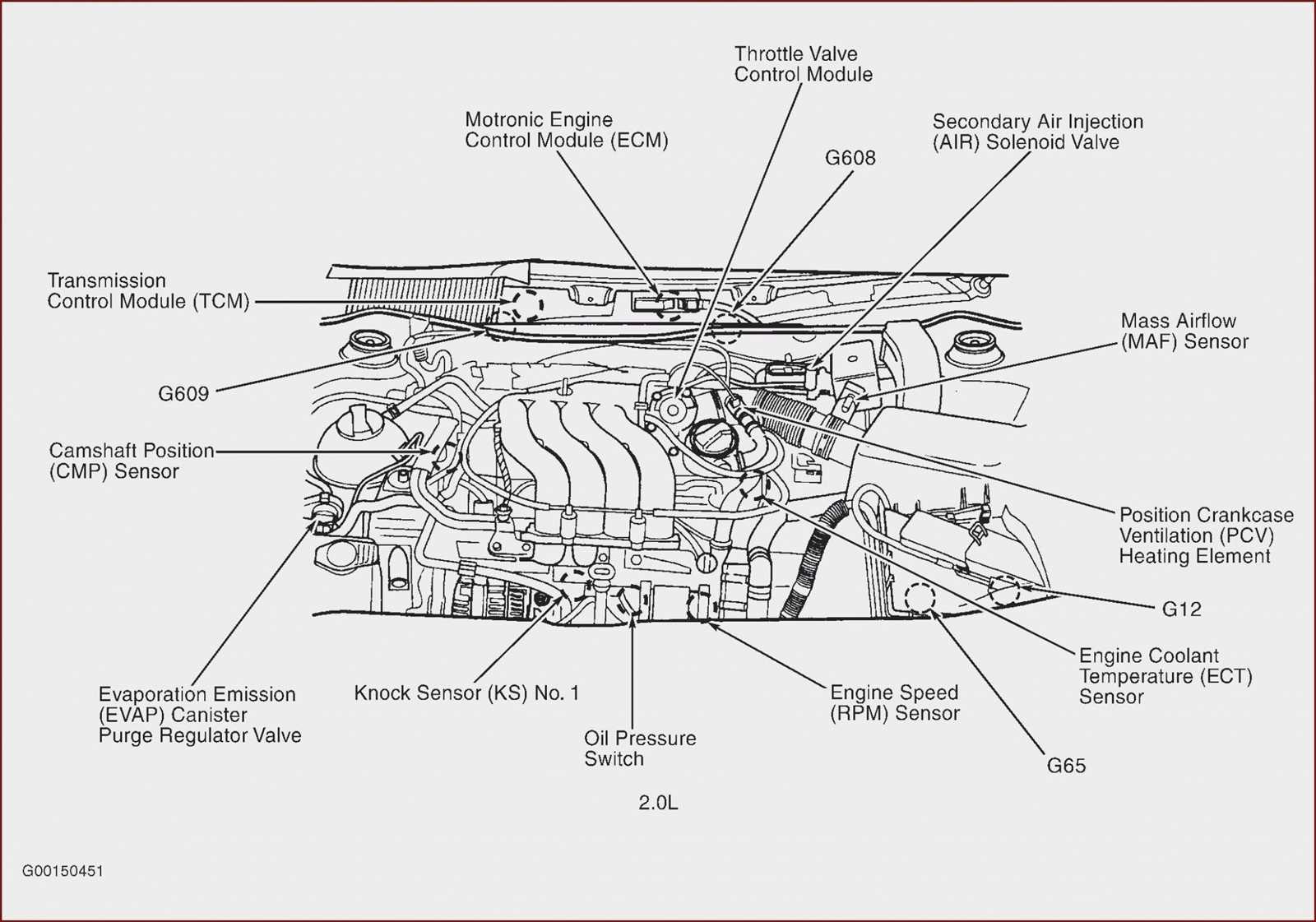

At the core of this system are the units that control fuel delivery, air intake, and exhaust output. Each of these systems is carefully calibrated to ensure that power is generated effectively, while minimizing waste and maximizing fuel efficiency. Understanding how they interact and support each other is crucial for anyone interested in optimizing performance.

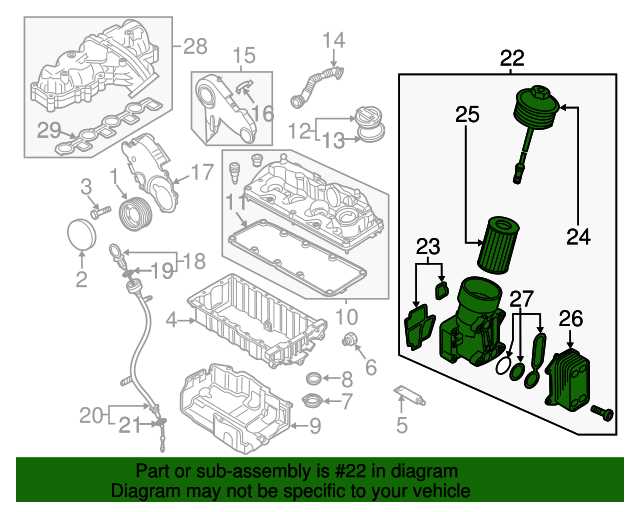

Supporting Systems for Longevity

Alongside the primary systems, there are supporting mechanisms that ensure long-term durability and reliability. These include cooling mechanisms, lubrication systems, and electrical components that help regulate temperature, reduce friction, and ensure consistent energy supply. Each plays a vital role in keeping the vehicle running smoothly over time.

How Each Part Affects Vehicle Performance

Each component within a vehicle’s core system plays a significant role in determining how it performs under various conditions. These elements, working together, directly influence factors such as power output, fuel efficiency, and overall smoothness of operation. By understanding how each section contributes to the whole, it becomes easier to appreciate the complexity of maintaining and optimizing vehicle performance.

The performance of the power unit is often determined by the interaction between fuel delivery, air intake, and exhaust systems. Each of these functions must operate at peak efficiency for the vehicle to run smoothly. A slight imbalance in one area, such as an inefficient fuel injector or a clogged intake, can have a ripple effect, reducing overall performance.

In addition to these critical elements, supporting systems such as cooling, lubrication, and electrical components are essential for maintaining stability and preventing overheating or wear. These systems ensure that the vehicle can run at optimal temperatures and without excessive friction, which in turn enhances both performance and longevity.

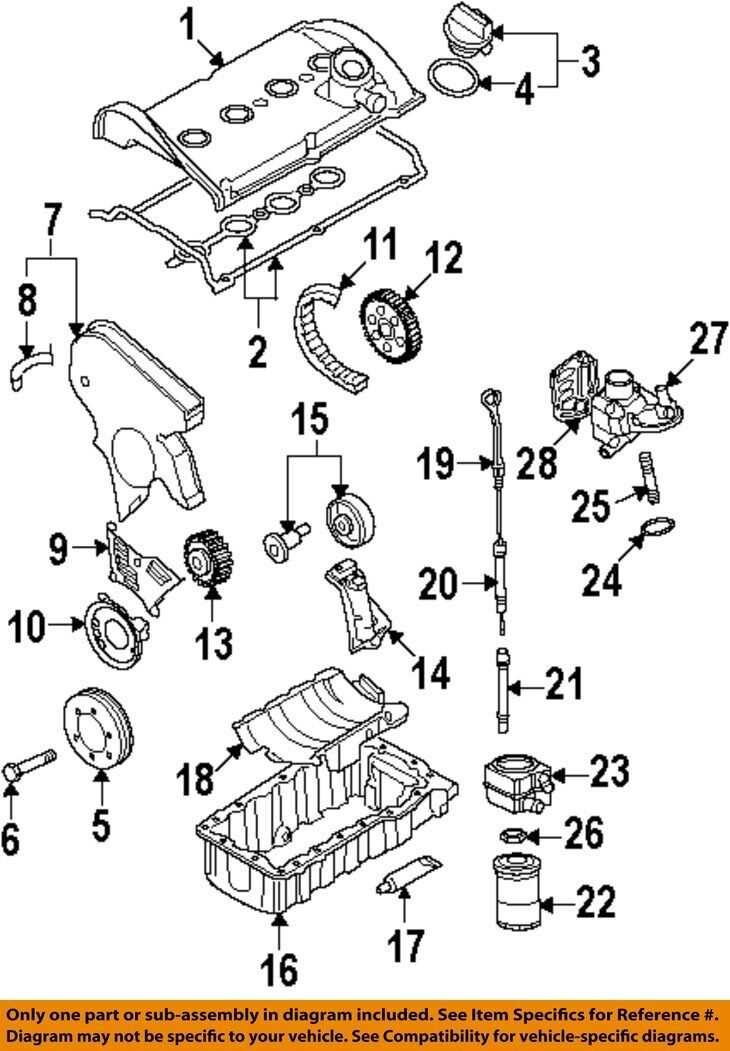

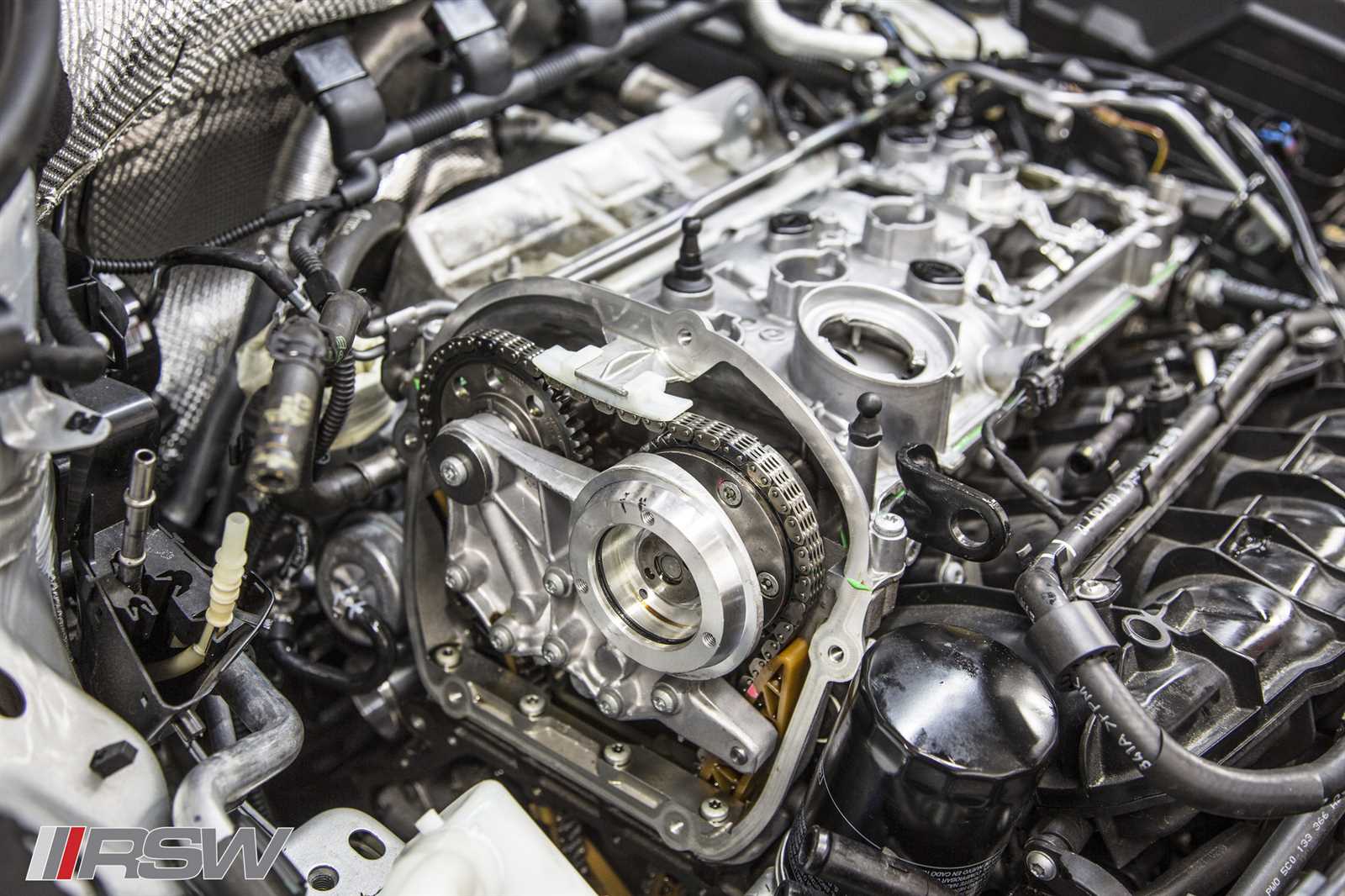

Exploring the Assembly and Layout

The arrangement of critical systems within a vehicle is designed to maximize efficiency and performance. By examining how each component is positioned, we can gain insight into how they work together to achieve optimal functionality. A well-thought-out layout ensures that the flow of energy, air, and fuel is managed effectively, directly impacting overall operation.

The positioning of these systems influences how power is generated and distributed. Elements such as the intake and exhaust channels are carefully routed to prevent interference and maintain a steady flow. Likewise, the cooling and lubrication systems are strategically placed to ensure effective heat dissipation and minimize friction, which helps maintain system integrity.

Understanding the overall arrangement allows for better diagnosis, optimization, and repair. When components are arranged logically, troubleshooting becomes simpler, and any adjustments can be made more efficiently to enhance performance or extend the lifespan of the unit.