Maintaining your outdoor equipment requires a clear understanding of its individual elements and how they function together. Whether you are performing repairs or upgrades, knowing the internal structure of your tool will help ensure efficient operation and long-lasting performance. This guide provides a comprehensive look into the key components of a popular lawn care device, making it easier for users to troubleshoot or replace parts when needed.

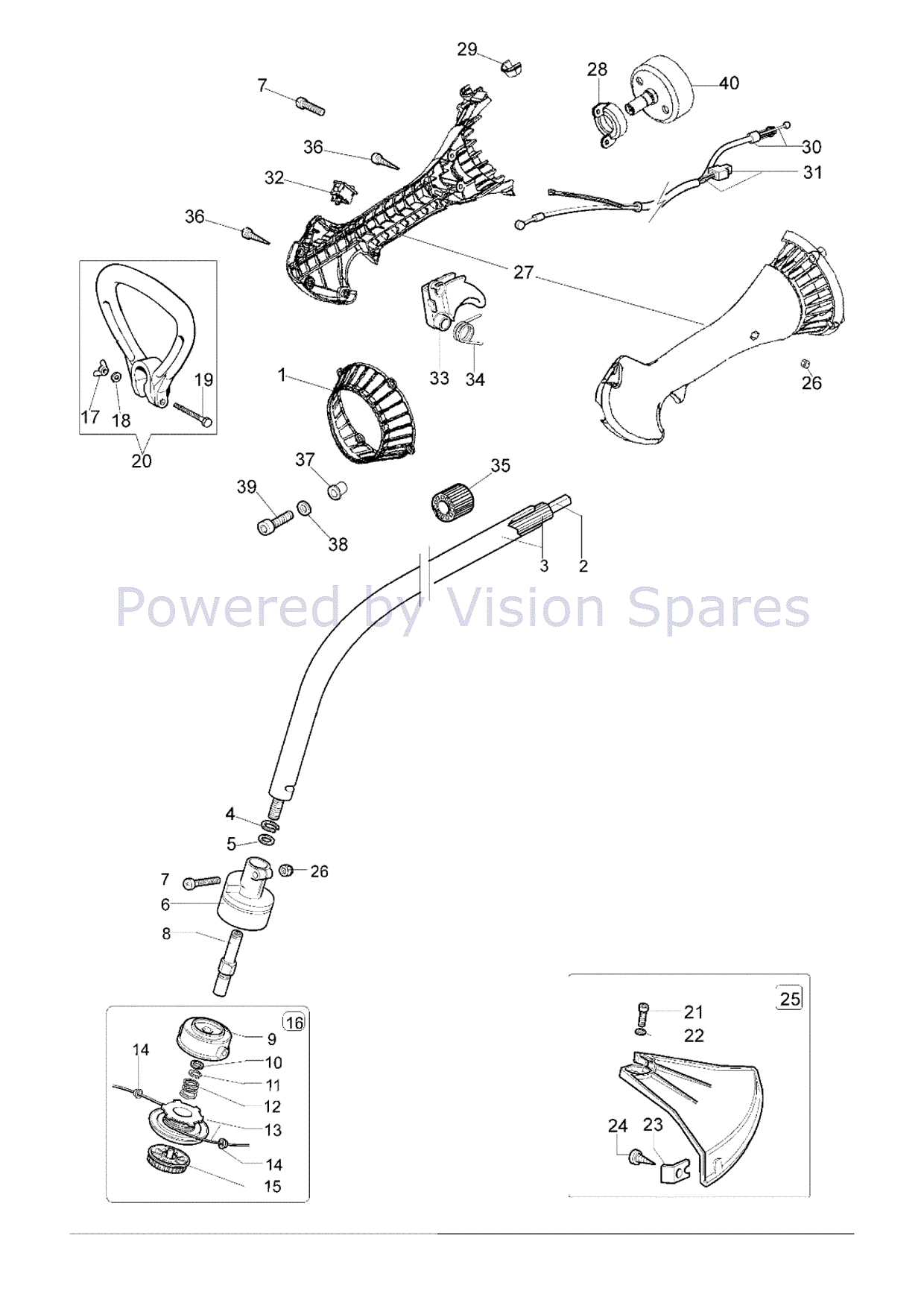

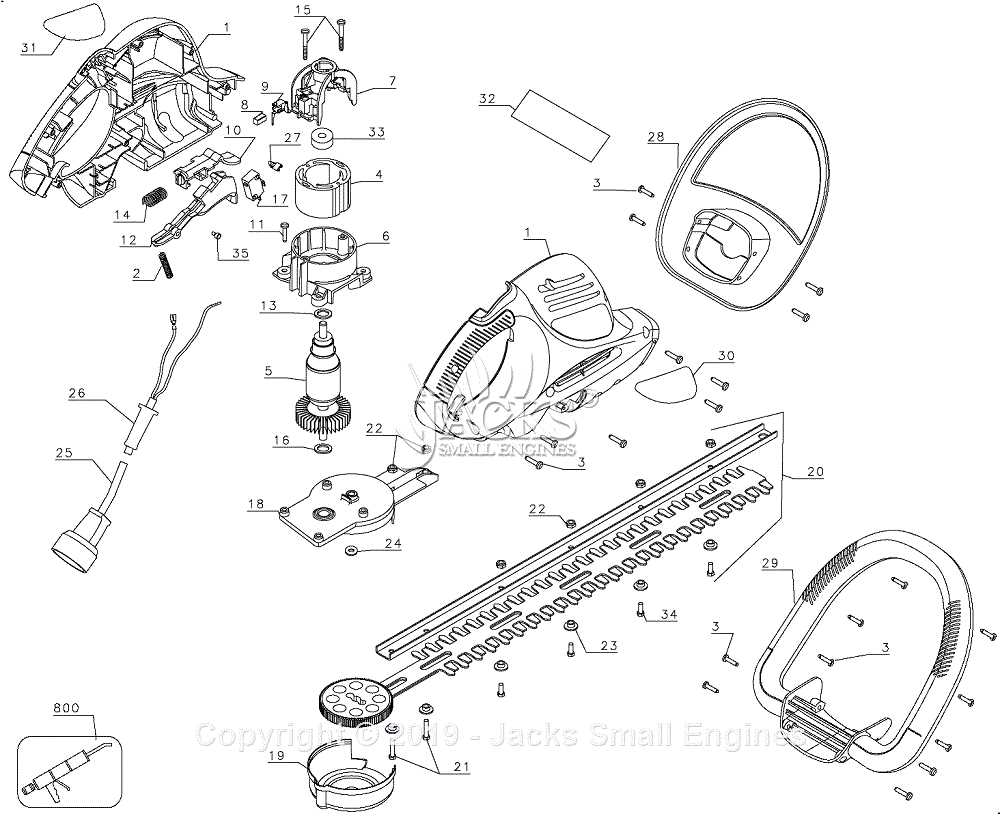

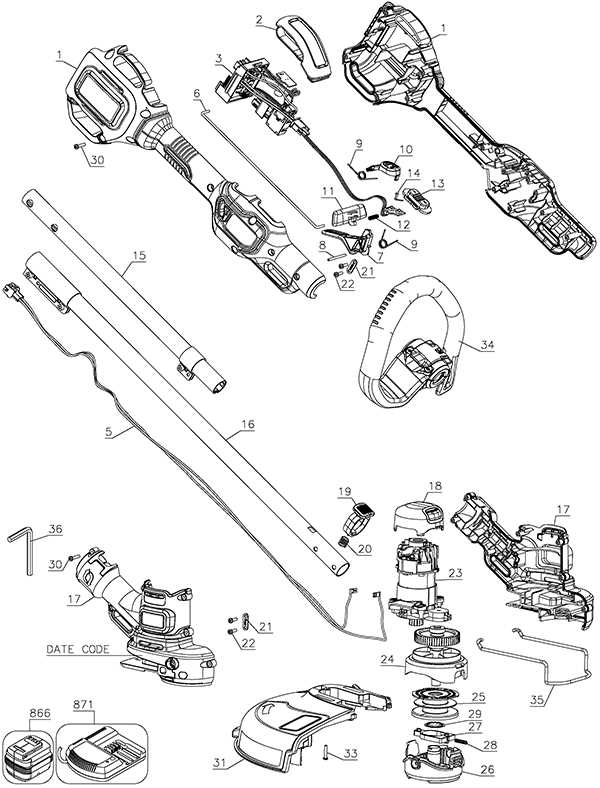

Visual guides are essential when identifying specific components within your trimmer. They offer a simple reference for users to match each piece with its corresponding function, reducing errors during maintenance. Understanding the role of each element will give you greater confidence when handling repairs or adjustments.

By gaining a deeper insight into the construction of your equipment, you can tackle common malfunctions or even upgrade certain features for better performance. With the right knowledge and resources, maintenance becomes more manageable, keeping your device in top working condition for years to come.

Understanding Trimmer Components

When working with lawn maintenance tools, it is crucial to familiarize yourself with their essential components. Each element plays a vital role in the device’s functionality and contributes to its overall performance. A well-maintained tool is a key to achieving efficient results and ensuring longevity. In this section, we explore the key components of your lawn tool, helping you understand their purpose and importance in operation.

Key Components of the Tool

The primary elements of your device include the motor, cutting mechanism, handle, and safety features. The motor powers the entire system, while the cutting mechanism is responsible for trimming the vegetation. The handle provides the user with a firm grip, ensuring precise control during use. Safety features such as protective guards are designed to prevent accidents and enhance the user experience.

Understanding the Assembly

Each component is carefully assembled to work in harmony with others. For example, the motor is connected to the cutting tool through a series of gears and shafts. These connections allow for smooth operation and optimal performance. Understanding how each part interacts will help when troubleshooting or performing repairs. Regular inspection of these connections ensures that everything is functioning properly, minimizing the risk of damage.

How to Read the Parts Diagram

Understanding visual guides is essential for effective maintenance of your equipment. These illustrations provide a clear overview of all critical components and their placement within the tool. By studying the guide, you can easily identify individual elements, making it simpler to perform repairs, replacements, or upgrades.

Identifying Components

The first step in reading a visual guide is identifying each labeled part. Each piece of equipment is shown with corresponding numbers or labels, making it easier to locate specific components. These identifiers are crucial when ordering replacement items or when troubleshooting specific issues related to a particular part.

Understanding Connections and Functions

Once you’ve identified the parts, it’s important to understand how they connect and interact within the system. The diagram will often include arrows or lines to show how various elements are connected. Knowing the relationships between parts allows you to troubleshoot efficiently and ensures that everything is reassembled correctly after maintenance.

Common Issues and Repair Solutions

When working with lawn equipment, it is common to encounter various issues that can affect performance. Understanding the most frequent problems and knowing how to fix them can save both time and money. This section will explore some typical malfunctions and their corresponding solutions, helping you keep your tool in optimal working condition.

One of the most common issues is a malfunctioning cutting mechanism, often caused by debris buildup or worn-out components. Cleaning the cutting area and replacing damaged elements will usually restore proper function. Another frequent issue is the motor failing to start, which can be attributed to battery problems or a loose connection. In such cases, checking the power source and ensuring all connections are secure should solve the problem. Regular maintenance and timely repairs are essential to avoid these issues in the future.