The efficient operation of a vehicle’s fuel delivery system depends on precise coordination between multiple components. A thorough understanding of these elements is essential for effective maintenance and troubleshooting. By breaking down the system into its core parts, mechanics can identify any issues and ensure optimal performance.

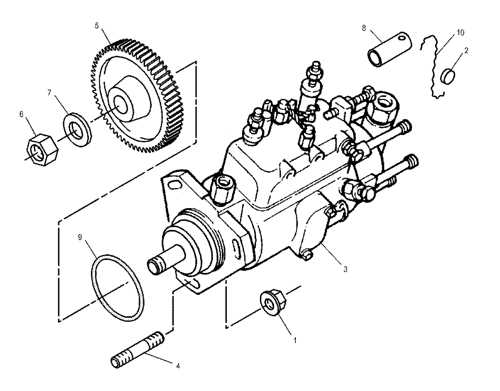

Detailed schematics serve as invaluable tools for anyone looking to repair or replace specific elements within the system. These visual aids provide a clear overview of the layout and connections, making it easier to pinpoint and address problems quickly. By referring to these guides, technicians can avoid unnecessary disassembly and save both time and effort during repairs.

Whether you’re a professional or a DIY enthusiast, familiarizing yourself with these resources is key to achieving reliable and long-lasting functionality. Properly interpreting the layout of each component will not only improve repair accuracy but also enhance the overall longevity of the vehicle’s performance.

Understanding the Fuel Delivery System

The fuel system in many vehicles and machinery relies on a highly specialized unit designed to manage the flow and regulation of fuel to the engine. This critical component ensures that fuel is delivered efficiently, at the right pressure, and in the appropriate amount to optimize combustion and engine performance. Its design and function are integral to both power generation and fuel economy.

How the System Works

At the heart of this mechanism, a precision-engineered device controls the timing and volume of fuel that enters the engine. It is activated by the engine’s rotational movement and works in tandem with other systems to ensure smooth operation. By controlling fuel flow with high accuracy, this unit helps prevent inefficient burning, reduces emissions, and maintains engine reliability.

Importance of Proper Maintenance

Regular maintenance of this system is essential for preserving the overall performance of the engine. Over time, wear and tear or contamination can affect its efficiency, leading to fuel delivery problems. Understanding the internal components and their relationships allows for better diagnostics, making it easier to identify potential issues before they result in costly repairs or decreased functionality.

Key Components of the Fuel Delivery Unit

The fuel delivery unit is made up of several vital elements that work together to regulate and control fuel flow. Each component plays a crucial role in ensuring that the engine receives the correct amount of fuel at the right time. A deep understanding of these parts can greatly improve troubleshooting and maintenance efforts.

One of the most important components is the rotary head, which controls the fuel distribution to each cylinder. It is driven by the engine’s rotation, ensuring the precise timing of fuel release. Another essential element is the plunger and barrel assembly, which helps maintain the pressure required for fuel delivery. The delivery valve works in coordination with these components, ensuring that fuel is delivered smoothly and at the right pressure to avoid performance issues.

Additionally, the governor regulates the engine speed by adjusting the fuel flow based on load conditions. This helps maintain a stable engine performance, even under varying operational conditions. Each of these parts must function harmoniously to ensure the system operates at peak efficiency and reliability.

How to Use the Fuel System Schematic

Understanding and utilizing a schematic of the fuel delivery unit is essential for anyone working on the system. A clear, detailed layout allows technicians and mechanics to quickly identify the components and their relationships, making maintenance and repairs more efficient. It serves as a valuable guide to ensure that each part is in its correct position and functions properly.

To make the most of the schematic, start by familiarizing yourself with the overall structure. Locate the major components and understand how they interact with each other. The diagram typically includes labels that correspond to specific components, which can help identify worn or damaged parts during a visual inspection. Additionally, pay attention to the flow of fuel through the system, as this will guide your troubleshooting process when issues arise.

When using the schematic for repairs or replacements, follow the instructions carefully to avoid errors. Ensure that each part is correctly reassembled and that no components are left out or misplaced. By using the schematic as a reference, you can significantly improve the accuracy and efficiency of your work, ensuring that the system operates as intended.