Every appliance designed to manage waste involves a variety of essential components working together to ensure smooth operation. These key elements are crucial in maintaining the device’s efficiency and longevity. Recognizing their roles can help users troubleshoot common issues and ensure proper maintenance.

Identifying each part and its function is the first step in understanding how to keep your unit running effectively. A clear understanding of the structure can save time during repairs and even help prevent future breakdowns. This guide will help you become familiar with the different components and their interconnected roles in the overall system.

By learning about these parts, you’ll be better prepared to address problems quickly and accurately. Whether you’re replacing worn-out pieces or performing routine checks, having a good grasp of the unit’s internal workings can make all the difference.

Essential Parts of Waste Compression System

To ensure that your waste reduction unit operates at peak efficiency, it’s important to understand its core components. Each element plays a vital role in how the machine functions, from compressing materials to safely disposing of waste. Proper knowledge of these critical elements allows for better maintenance and quicker troubleshooting.

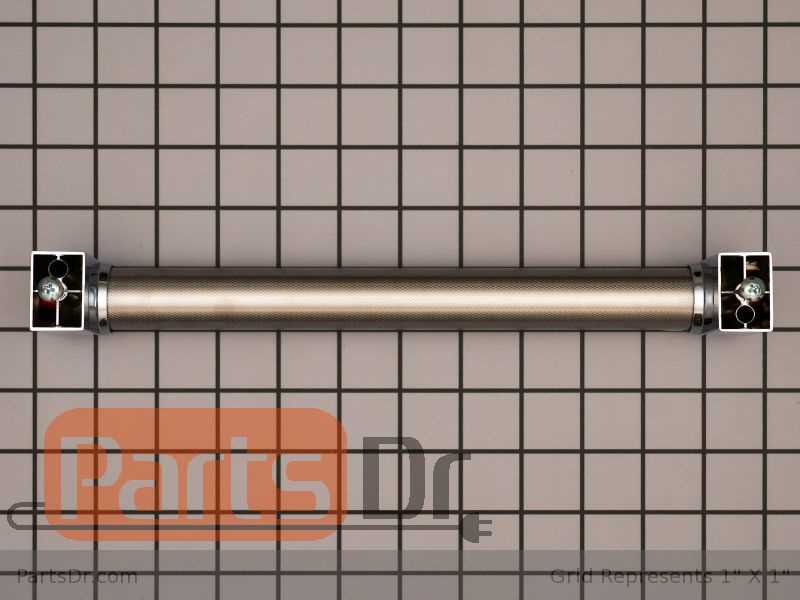

Key components like the motor, ram, and drive system are integral to the unit’s performance. The motor powers the entire mechanism, while the ram is responsible for applying pressure to the waste. Additionally, the drive system connects all moving parts, ensuring everything operates smoothly. A failure in any of these components can disrupt the entire system, highlighting the importance of regular maintenance and timely repairs.

Other supporting parts such as the control panel, safety features, and door latch provide operational control and user safety. These elements, though less visible, are equally important for ensuring a smooth and safe experience with the machine. Understanding each part’s function helps ensure optimal performance and prevents unexpected malfunctions.

Understanding the Waste Compression Mechanism

At the heart of any waste management system lies a mechanism designed to reduce the volume of materials efficiently. This mechanism relies on several interconnected elements working together to perform the task. From activating the compression force to managing the collected waste, each step is vital for ensuring that the unit operates smoothly.

The core of the system involves a motor that generates the necessary power to drive the action. Once activated, the motor triggers the movement of key components, including the ram, which applies the pressure to compress the waste. This sequence of movements is controlled by a series of sensors and switches, ensuring that the system functions without interruption.

Understanding how these components interact allows users to identify potential issues early on and take the necessary actions for repair or maintenance. By recognizing the role of each element in the mechanism, you can better appreciate how the machine works as a whole and ensure that it continues to operate efficiently over time.

Common Issues and Part Replacements

Even the most reliable waste management systems can experience issues over time. These problems can range from simple malfunctions to more complex failures in the core components. Identifying the root cause early is key to minimizing downtime and restoring the unit to optimal working condition. Knowing which components are most likely to need replacement helps streamline the repair process.

Motor and Drive System Failures

The motor is one of the most critical components in the system. Over time, wear and tear can lead to reduced performance or even complete failure. If the motor is not functioning correctly, the compression mechanism may not engage properly, leading to inefficiency. In such cases, replacing the motor or the drive components is often necessary to restore full functionality.

Compression Ram Issues

The ram, which applies the pressure to compact the waste, can also experience problems. Common issues include misalignment, motor failure, or damage from excessive force. If the ram is not moving as intended, it may need to be replaced or adjusted. Regular inspection of this part is crucial to ensure smooth operation and prevent further damage to surrounding components.