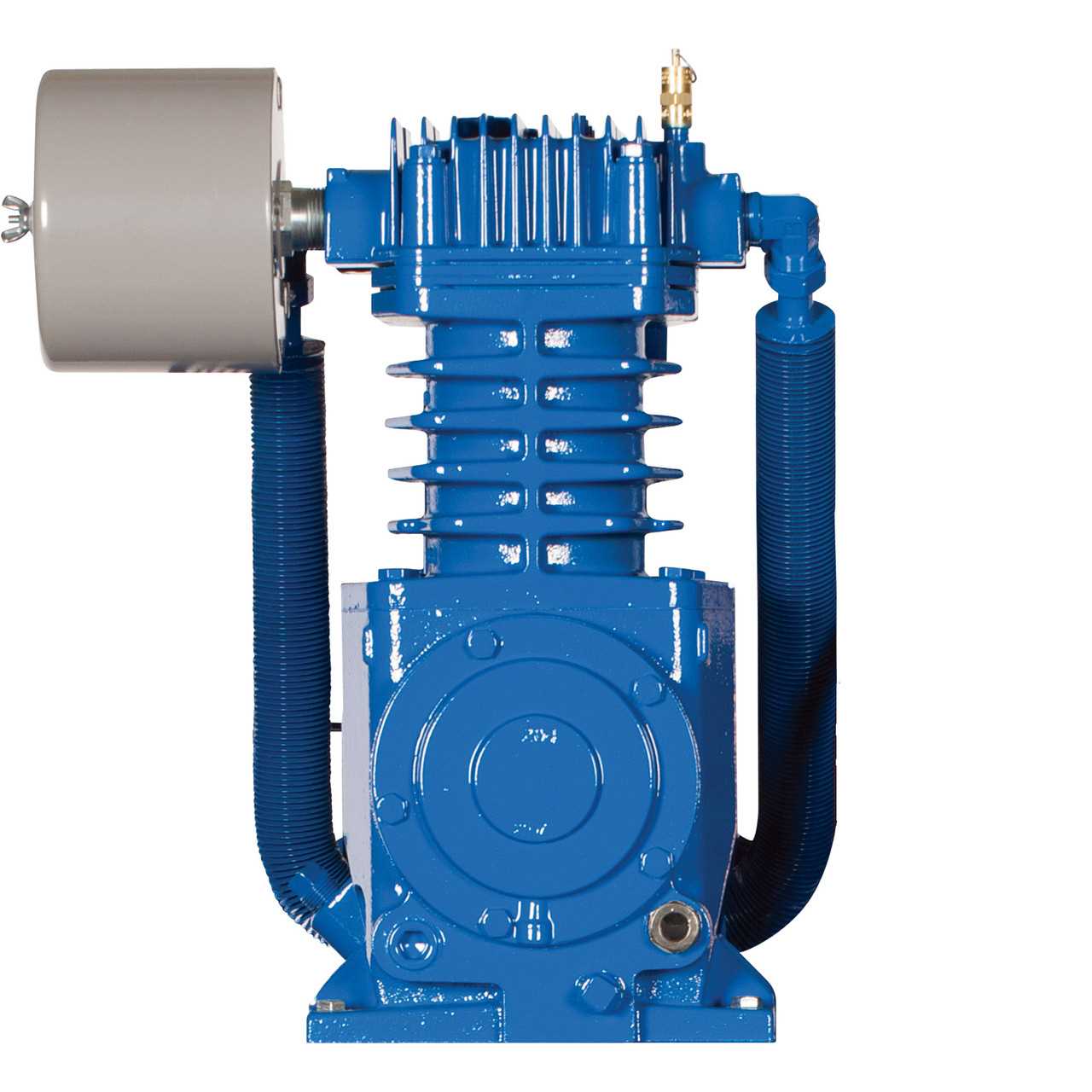

In any mechanical system, knowing how each component works and interacts is crucial for efficient maintenance and repair. Understanding the layout and function of key elements allows users to troubleshoot issues and perform necessary replacements with ease.

Having a clear visual representation of these components is a valuable resource for anyone working with such machinery. It simplifies identifying parts, understanding their placement, and recognizing common failure points. This knowledge is especially important for avoiding unnecessary repairs and ensuring long-lasting performance.

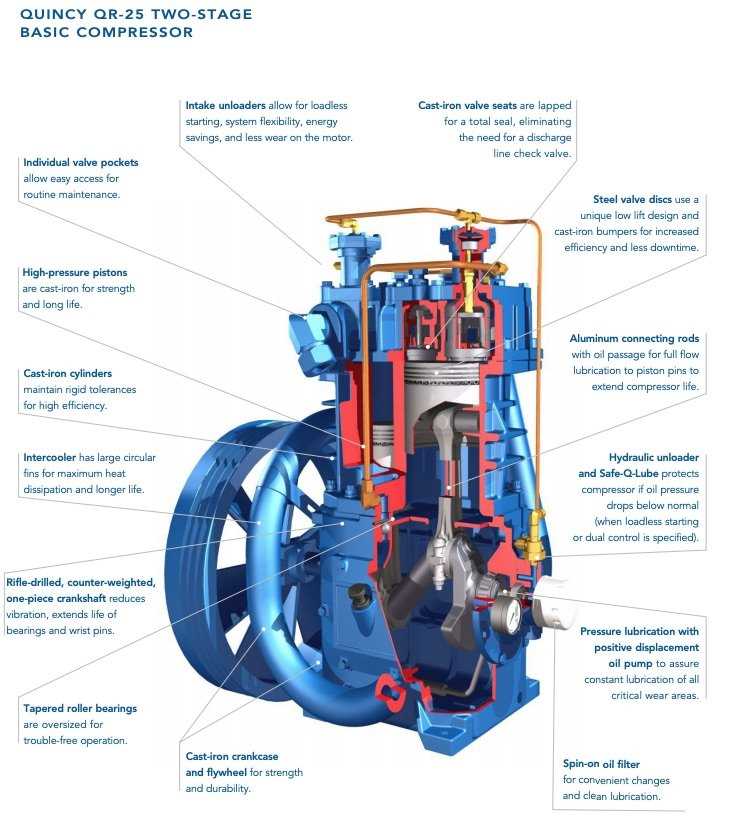

Understanding Internal System Components

To effectively maintain any mechanical system, it’s essential to have a comprehensive understanding of its individual elements. Knowing how each component contributes to the overall function can significantly enhance troubleshooting and repair efforts. By identifying the role of each section, users can address issues promptly and avoid unnecessary disruptions in operation.

Each component plays a distinct part in the system’s overall efficiency, from the core elements responsible for generating power to the auxiliary components that manage airflow and cooling. Understanding these functions helps users identify where problems might arise and determine the most effective solutions.

Familiarity with the system’s structure and layout ensures that any necessary replacements or adjustments can be made quickly and accurately. With this knowledge, maintenance becomes less about guesswork and more about targeted, precise action to keep everything running smoothly.

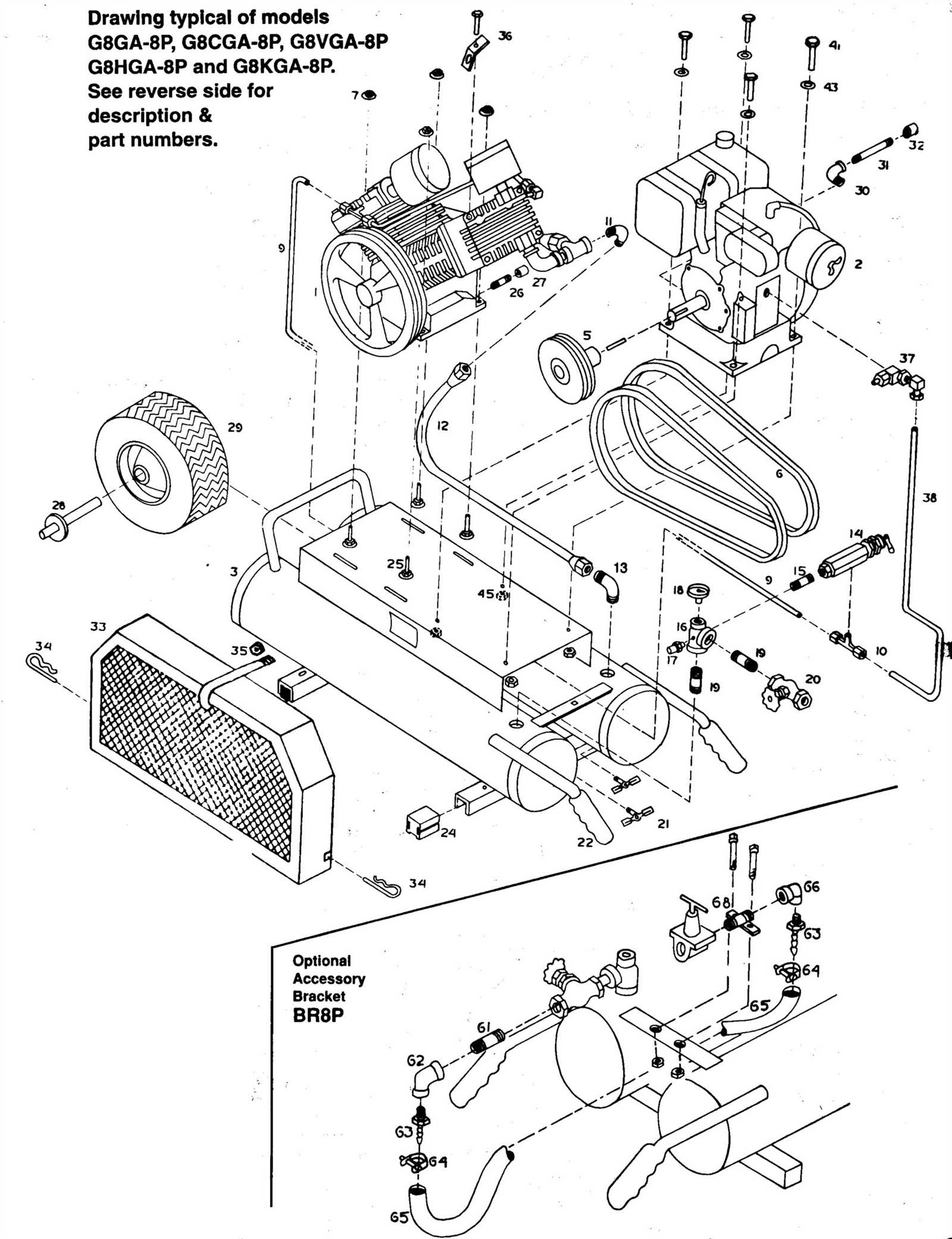

How to Read an Internal System Layout

Understanding technical layouts is essential for effective repairs and maintenance of any mechanical system. These visual representations offer valuable insights into how individual elements are arranged and interact. A proper understanding of these diagrams makes troubleshooting easier and helps identify the root cause of any issues quickly.

When analyzing these layouts, focus on key symbols and connections. Each part is represented by specific shapes and lines, which indicate its function and relationship with other components. Familiarize yourself with the legend or key provided, as it explains the meaning of each symbol used in the layout.

Once you understand the general layout and symbols, follow the flow of the system. Pay attention to the connections between components, such as pipes or electrical connections, and observe how energy or air moves through the system. This will help you locate potential issues and plan for necessary repairs or replacements more efficiently.

Common Issues and Part Replacements

Mechanical systems are prone to wear and tear over time, leading to various malfunctions. Recognizing the signs of these issues early can prevent further damage and ensure the system continues to function efficiently. Many of these problems are linked to specific components that may need to be replaced to restore full functionality.

Common problems include reduced efficiency, irregular operation, and unusual sounds. These symptoms often point to worn-out or damaged elements, such as seals, valves, or filters. Identifying the faulty component based on these signs is the first step in addressing the issue.

When it’s time to replace a part, using the correct replacement is crucial. Refer to the system layout to find the exact specifications for each component. Using a mismatched part can cause further damage, leading to more complex and costly repairs. Proper replacement ensures smooth operation and extends the lifespan of the system.