When maintaining a mobile sanitation system, it’s crucial to understand the different components that make up the unit. A clear understanding of each part’s function and how they interact will help you keep the system running smoothly. Whether you’re dealing with issues related to flushing mechanisms or water flow, knowing the layout of these components can save you time and effort in troubleshooting.

Identification and organization of the various components ensure that users can make informed decisions during repairs or replacements. An efficient setup is vital for ensuring long-lasting performance and avoiding frequent breakdowns.

Regular maintenance of key elements prevents common problems and improves overall system efficiency. By recognizing the parts involved, you can address potential issues before they become major concerns, ensuring a more comfortable experience during use.

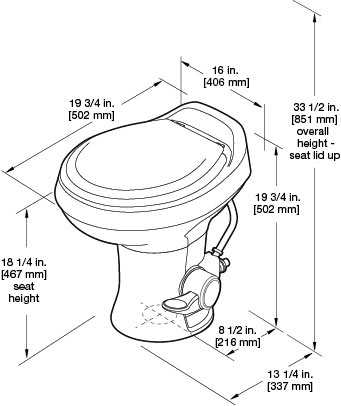

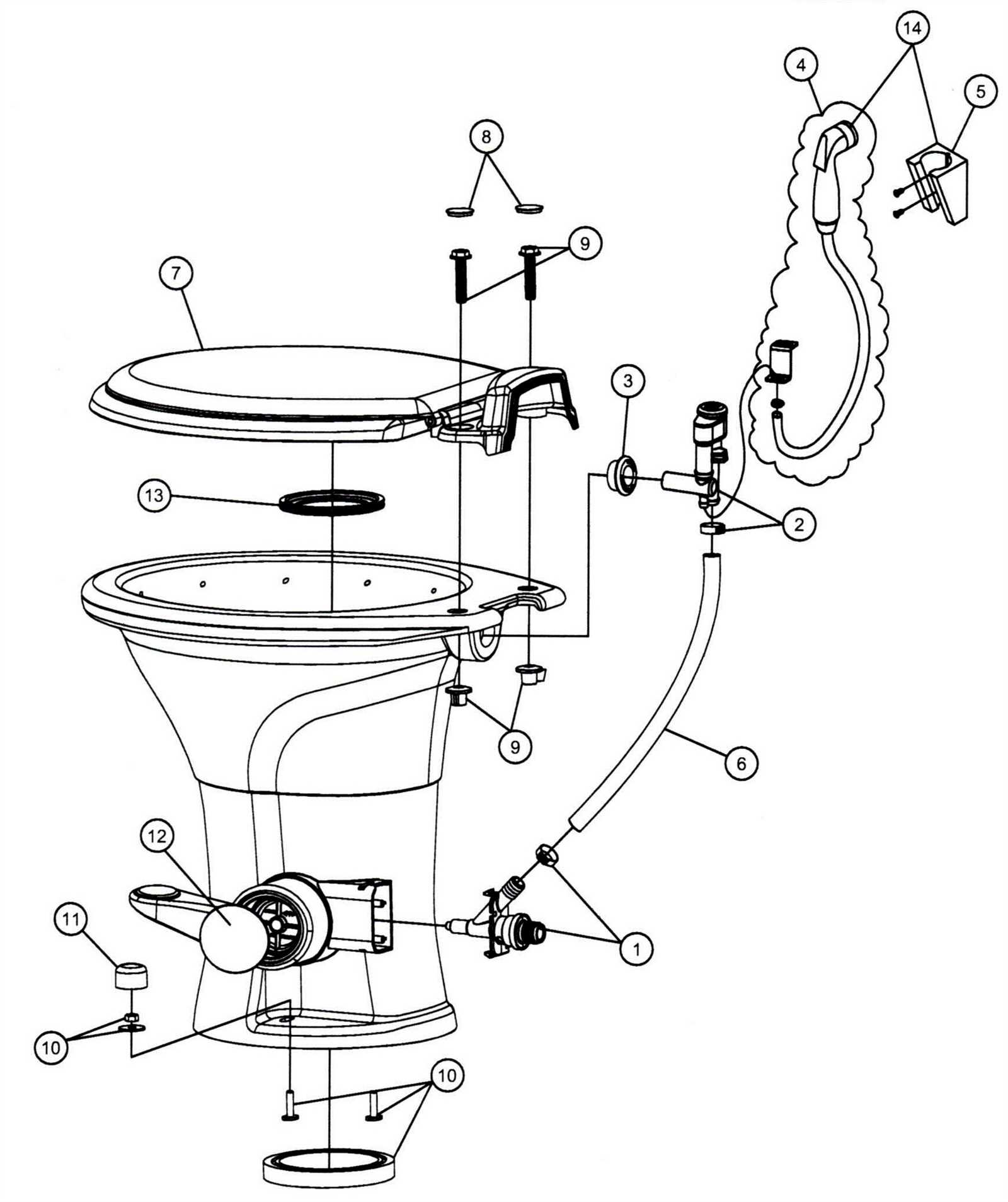

Understanding the Dometic 310 Toilet Components

Proper functioning of a sanitation system relies on the interaction of multiple internal components, each serving a specific role. Recognizing how these elements work together can help users diagnose issues quickly and maintain a smooth operation. From water flow control to waste management, every part plays a crucial role in ensuring efficiency.

Key Components in the System

At the core of this setup are the flush mechanism and the water valve, which regulate the flow and ensure proper disposal. These essential components work together to provide an effective flushing process, preventing blockages or inefficiencies. Another vital element is the seal system, which keeps everything secure and prevents leaks that could lead to malfunctioning.

Maintaining Efficient Performance

Understanding the different pieces involved allows for better upkeep and helps avoid common issues like clogging or water leakage. Regular cleaning and occasional inspection of each component can extend the life of the system. Whether it’s replacing worn-out seals or cleaning the flush valve, maintaining these elements ensures a hassle-free experience and efficient functionality.

Common Issues with Dometic 310 Parts

Over time, certain elements of a mobile waste management system can begin to show signs of wear, leading to performance issues. These problems can range from minor inconveniences to more significant malfunctions that affect the system’s functionality. Identifying common issues early on can help prevent costly repairs and ensure consistent operation.

Clogs and Blockages

One of the most frequent issues encountered is clogging, often caused by improper disposal or the accumulation of debris within the system. Blockages in the waste pathways or the flush mechanism can lead to slow drainage, weak flushing, or even complete system failure. Regular maintenance and the use of appropriate cleaning products can help prevent this common problem.

Leaks and Water Flow Issues

Another issue that users may face involves leaks or irregular water flow. This could be due to worn-out seals, faulty valves, or corroded parts that no longer provide a tight fit. When water leaks occur, it not only impacts functionality but can also cause water damage to surrounding areas. Ensuring that seals and connections are checked regularly can prevent such issues.

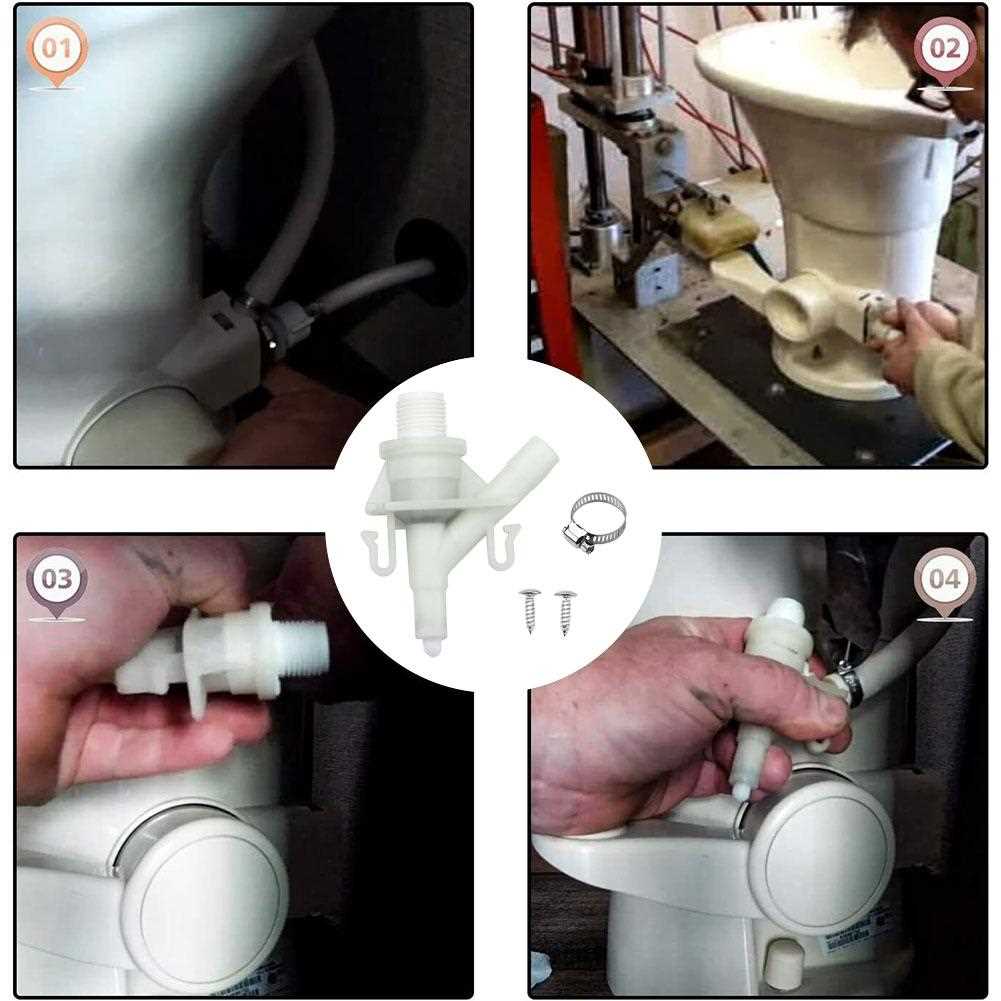

How to Maintain Dometic 310 Toilet Parts

Regular maintenance is essential for ensuring that a mobile sanitation system operates efficiently and lasts for years. By taking simple, proactive steps, you can prevent many common issues and ensure the smooth operation of the system. The key to effective maintenance is understanding each component’s role and addressing any signs of wear before they escalate into bigger problems.

Cleaning and Inspecting Components

One of the most important tasks is cleaning the various elements, such as the flush valve and water seals. These parts should be cleaned regularly to prevent build-up that can cause blockages or malfunctions. Inspecting components for any signs of wear, such as cracks or corrosion, can also help identify potential issues early. Pay close attention to the seal system as damaged seals can lead to leaks or reduced efficiency.

Replacing Worn-out Parts

Over time, certain components will naturally wear out, requiring replacement. Items such as seals, valves, and flushing mechanisms should be replaced as needed to maintain optimal functionality. Ensuring that these parts are always in good condition will help prevent water leakage, slow drainage, and other common problems. Always use high-quality replacement parts to ensure longevity and performance.