When it comes to maintaining and repairing a chainsaw, having a clear understanding of its internal structure is essential. Every component plays a crucial role in the tool’s overall performance, and knowing how each part interacts can make troubleshooting much easier.

Familiarizing yourself with the different sections of your chainsaw will help ensure that it operates smoothly and efficiently. Whether you’re replacing a damaged part or performing routine maintenance, having a comprehensive view of the machine’s build can guide you through the process with confidence.

Accurate identification of components is key to proper care. By examining the layout and function of each part, you can enhance the lifespan of the tool and avoid common issues, making your chainsaw ready for any task at hand.

Understanding the Chainsaw Components

To properly maintain and troubleshoot a chainsaw, it’s important to familiarize yourself with its key components and their functions. Each element contributes to the overall efficiency and safety of the tool, making it essential to understand how they work together.

Key Elements of the Chainsaw

The main components of a chainsaw include the engine, bar, chain, and various internal mechanisms that control movement and power. Each part plays a vital role, from powering the chain to ensuring smooth operation. The engine is responsible for generating the force needed for the chain to cut through wood, while the bar guides the chain’s motion.

Internal Mechanisms and Maintenance

Inside the chainsaw, various small components, such as the clutch and sprocket, ensure the proper transfer of power from the engine to the chain. Regular inspection and maintenance of these internal mechanisms help prevent wear and tear, which can affect the performance of the chainsaw over time.

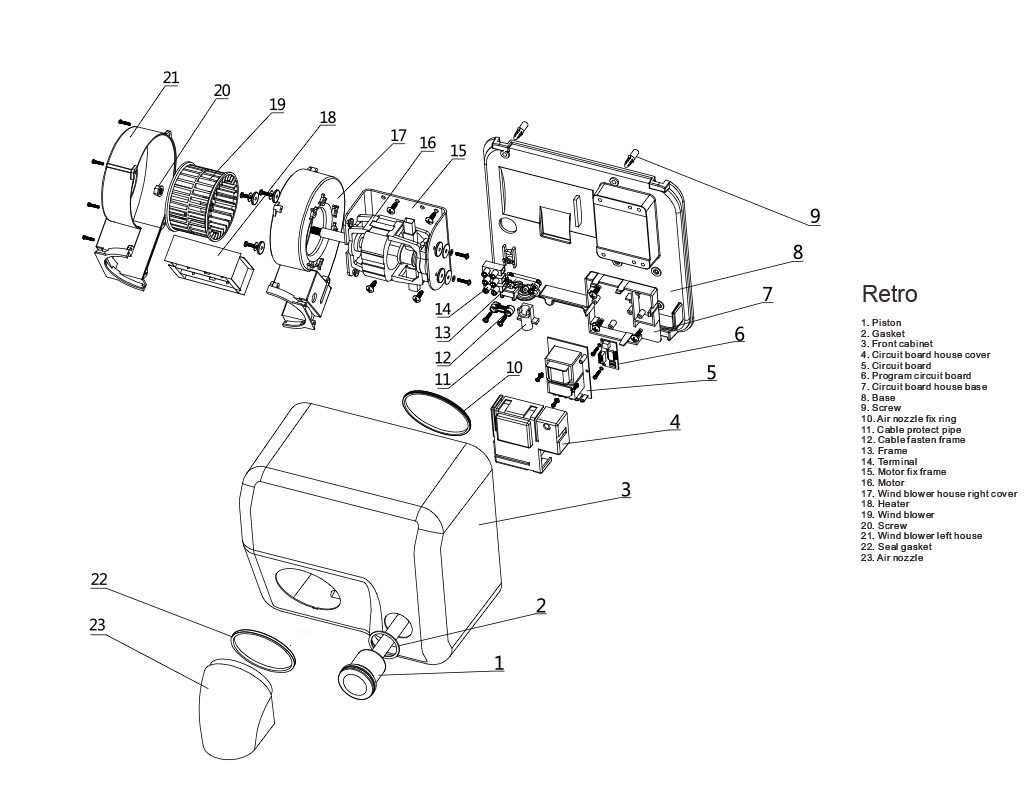

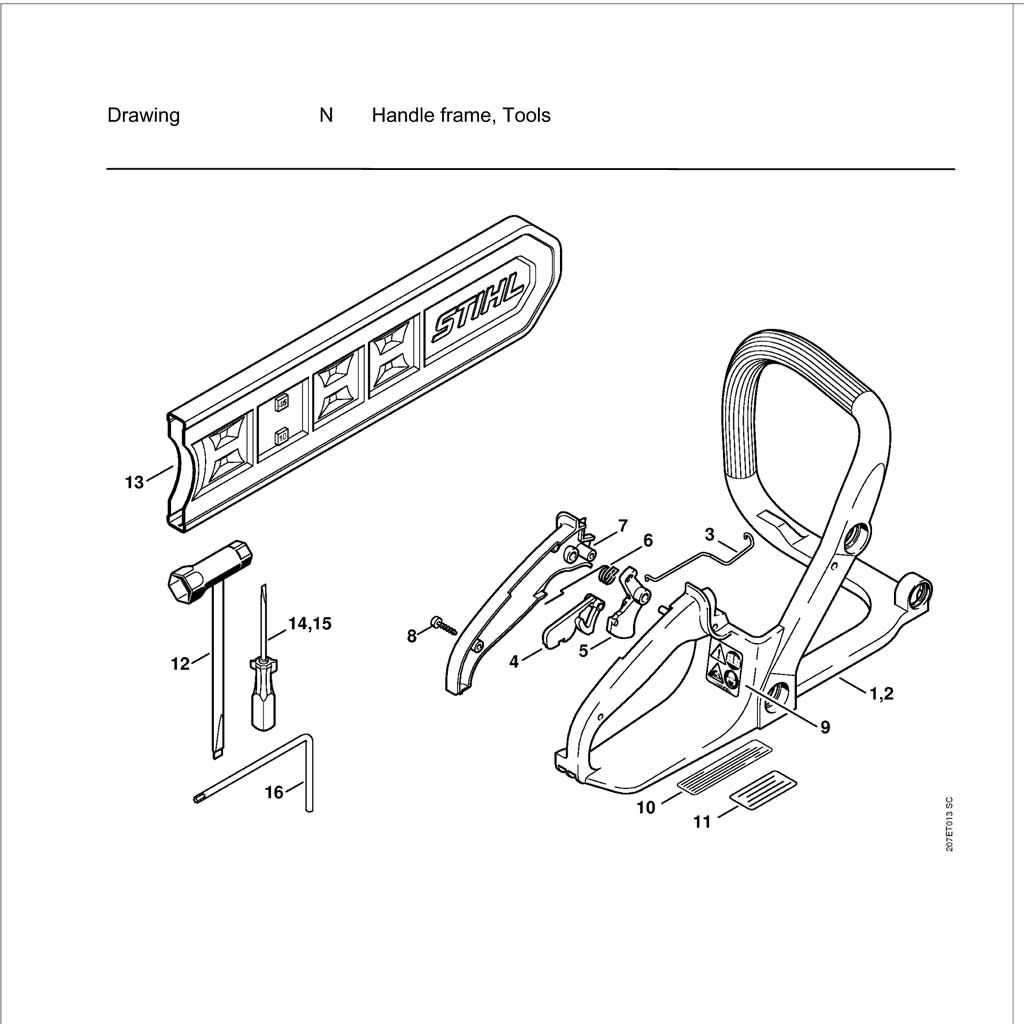

How to Read the Chainsaw Assembly Overview

Understanding a tool’s internal layout is key to efficient maintenance and repair. An assembly guide offers a visual representation of all the components and how they fit together, allowing for easy identification and troubleshooting. By interpreting these visuals correctly, you can effectively assess the condition of each piece and replace or repair as necessary.

Focus on the key symbols and numbers provided within the assembly guide. These often correspond to specific parts, showing their position within the system. Familiarizing yourself with these markers helps you quickly locate parts that need attention or replacement without unnecessary disassembly.

Pay attention to the relationships between the components. The guide not only shows individual parts but also how they connect to one another. This understanding will help you avoid mistakes when reassembling the tool and ensure everything is aligned for proper functionality.

Essential Parts for Chainsaw Maintenance

Proper care of a chainsaw requires attention to several critical components that ensure its smooth operation. These key elements are essential not only for performance but also for safety. Regular maintenance of these components can extend the life of the tool and prevent costly repairs down the line.

The engine is the heart of the chainsaw, responsible for generating the power needed for cutting. It is important to regularly check the spark plug, air filter, and fuel system to ensure they are functioning correctly. Additionally, the chain and bar require routine inspection and lubrication to maintain efficiency during use.

Internal mechanisms like the clutch, sprocket, and tensioner are also vital for smooth operation. These parts should be cleaned and checked periodically to prevent excessive wear and ensure optimal power transfer from the engine to the chain.