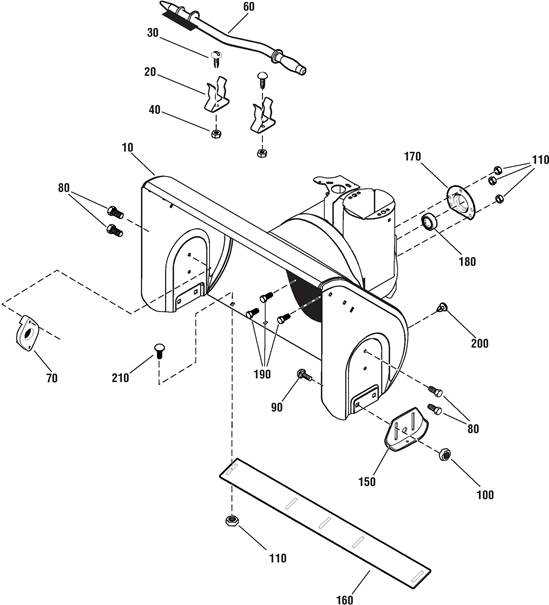

When it comes to maintaining and repairing outdoor machinery, having a clear visual guide of its components can make a significant difference. A comprehensive schematic not only helps identify each individual piece but also enhances the overall efficiency of the repair process. Knowing where each part fits into the larger system ensures that any issues can be diagnosed and resolved quickly, saving time and effort.

Detailed illustrations provide a well-organized view of the internal and external components, showcasing how everything works together. Whether it’s for troubleshooting, replacement, or upgrades, these helpful resources give you a clearer perspective on the machine’s layout.

Accurate references become essential tools for anyone looking to understand the inner workings of their equipment. With a properly labeled guide, even those with minimal technical knowledge can approach maintenance tasks with confidence. By taking a closer look at these visual aids, you can maintain your machinery’s performance and longevity with ease.

Understanding the Ariens Deluxe 28 Parts

Having a clear understanding of your equipment’s components is essential for proper maintenance and troubleshooting. Whether you’re fixing a malfunction or performing routine checks, knowing how each element fits and functions can prevent mistakes and improve performance. A thorough knowledge of the machinery’s build enables better decision-making when it comes to repairs or upgrades.

The Importance of Internal Mechanisms

The internal mechanisms of your device work together to ensure smooth operation, and a breakdown of these systems can help identify potential issues early on. Key components like the engine, drive system, and auger work in tandem to provide optimal results, and understanding how they interconnect is critical for effective servicing. Proper maintenance of these internal parts guarantees longevity and reliability.

External Components and Their Role

External elements like the housing, chute, and handles play a vital role in the functionality and user experience. These parts must be inspected for wear and tear as they can affect the overall performance. Regular inspection of these visible components ensures that the equipment remains safe and ready for use in any conditions.

Step-by-Step Guide to Identifying Key Components

Understanding the crucial elements of your equipment is essential for efficient repairs and maintenance. This guide will walk you through the process of identifying the primary components that contribute to the overall functionality. By recognizing each part’s role and location, you can troubleshoot issues and ensure that the system is operating at its best.

Start with the Engine and Power Systems

The engine is the heart of the machine, providing the power needed for operation. Begin by locating the engine and familiarizing yourself with its key features, such as the fuel intake, spark plugs, and air filters. Checking these components regularly for signs of wear or blockage can prevent many common issues and improve overall performance.

Inspecting the Chassis and Drive Mechanism

The chassis and drive system form the structural foundation and movement capabilities of the equipment. These components are responsible for how the machine interacts with the ground or surface. Pay attention to elements like the wheels, drive belts, and transmission system. Maintaining these parts ensures that the device operates smoothly and with minimal resistance.

How to Use the Ariens Parts Diagram for Repairs

Knowing how to use a visual guide for identifying components is essential for effective maintenance and repairs. By referencing a clear schematic, you can locate the faulty parts, understand their roles, and determine the steps necessary for replacement or adjustment. This approach streamlines the repair process and minimizes the risk of further damage.

Step 1: Identify the Faulty Component

The first step is to accurately diagnose the problem. With the help of a reference guide, locate the malfunctioning part. Check for common signs like unusual sounds, poor performance, or visible damage. Once you identify the issue, you can proceed with finding the specific part and tools needed for the repair.

Step 2: Use the Guide to Understand the Layout

Next, refer to the guide for an overview of the system’s layout. This will give you a clearer understanding of how the different parts interact. Follow these steps:

- Locate the general area where the faulty component is situated.

- Examine its connection to other parts to identify if there are any additional areas requiring attention.

- Take note of part numbers and corresponding details for easy ordering or replacement.

Step 3: Perform the Repair or Replacement

With the faulty component identified and the layout understood, gather the necessary tools and replacement parts. Carefully follow the instructions to remove the old part and install the new one. Be sure to check that everything fits securely and functions properly before reassembling the device.