When maintaining outdoor power tools, knowing the structure and individual elements is crucial for proper upkeep. By becoming familiar with each piece, you can identify any issues quickly and efficiently, ensuring your equipment runs smoothly for longer periods.

Having access to a visual guide that highlights all the key elements of your machine can be a game-changer. It allows for easy identification of specific components, whether you’re replacing, cleaning, or conducting a general inspection.

With the right resources, the process of managing your tool’s maintenance becomes straightforward and effective. Utilizing a reference material can significantly simplify the task of finding the necessary parts and ensuring everything is in working order. Proper knowledge helps you avoid unnecessary repairs and keeps your equipment functioning at its best.

Stihl FS 55 Parts Breakdown Guide

For efficient maintenance and repairs, it’s essential to have a clear understanding of the individual components of your equipment. Recognizing how each piece fits into the overall machine helps to troubleshoot problems, replace worn-out parts, and ensure your tool operates optimally. Having a detailed reference makes these tasks more manageable and accurate.

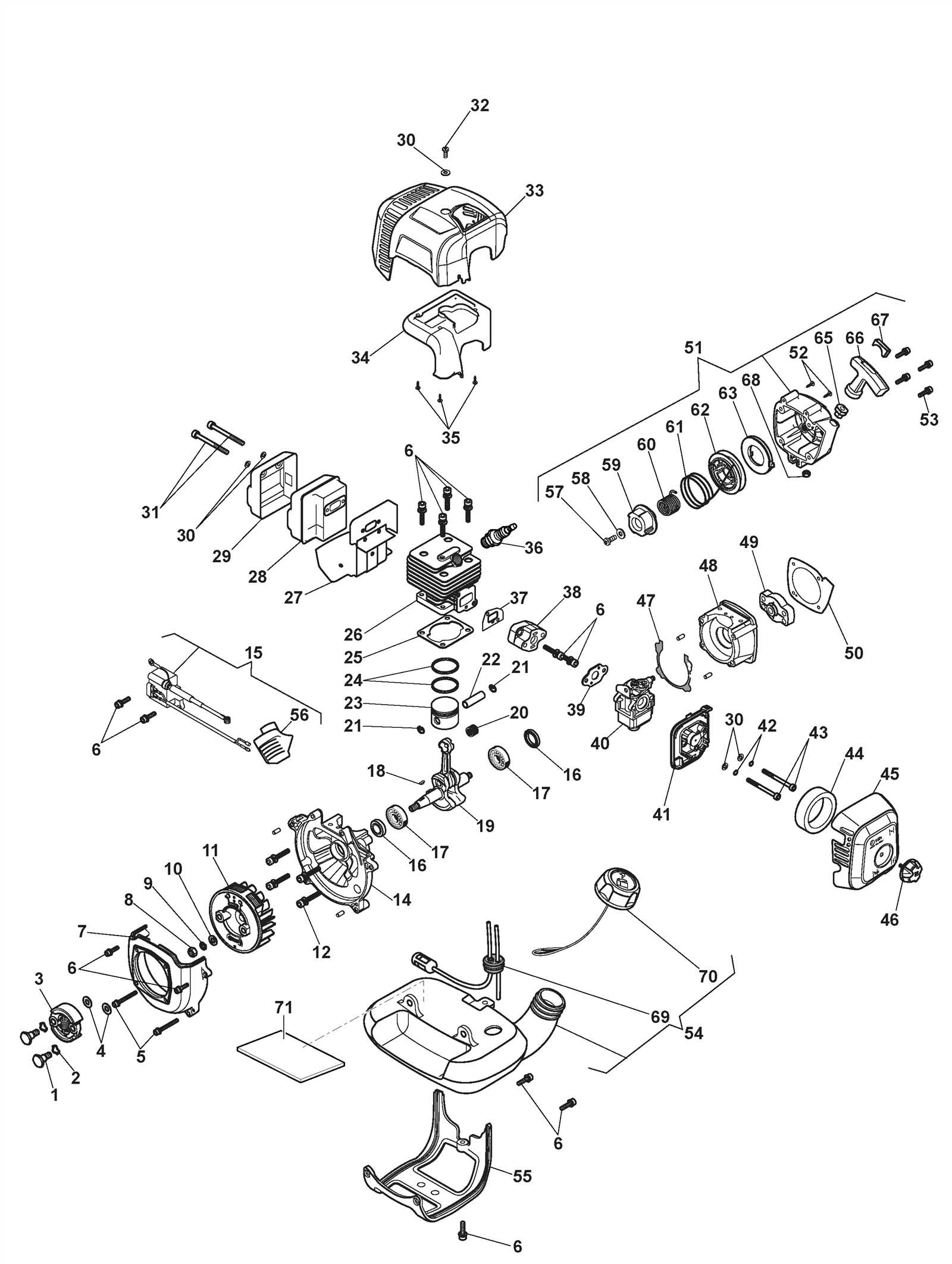

Key Components Overview

Each tool contains a range of elements, from the engine to the small accessories, each playing a vital role. By identifying these parts, you can more easily isolate the source of any malfunction or damage. Whether it’s the cutting head, motor, or protective housing, knowing what each section does simplifies both repairs and upgrades.

How to Identify and Replace Parts

Identifying a malfunctioning part is the first step in addressing an issue. Once you pinpoint the defective element, finding a replacement becomes much simpler. Understanding the layout allows for efficient troubleshooting, reducing downtime and enhancing the lifespan of your equipment. Quick repairs are achievable when you know where to look and what to replace.

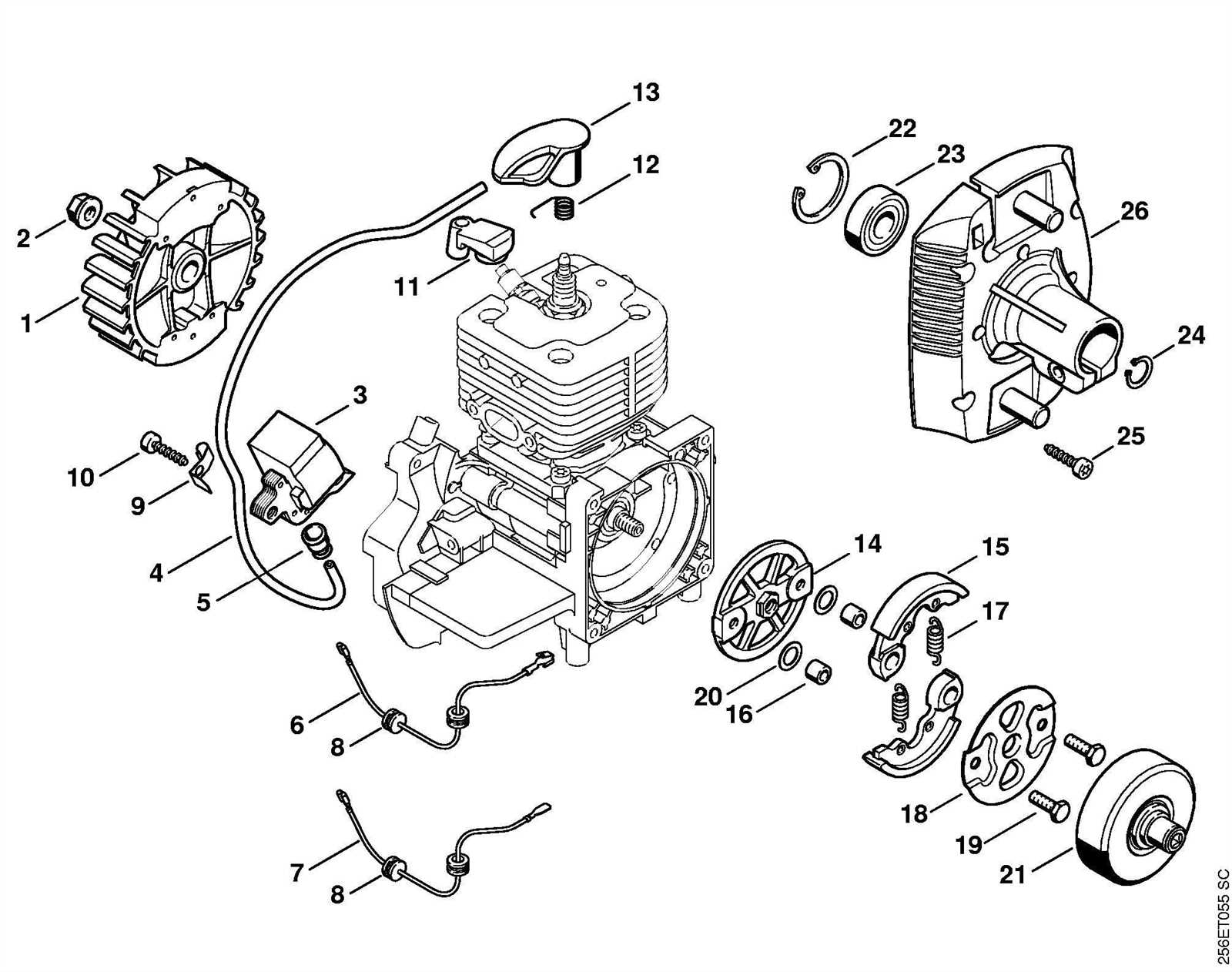

Understanding the Components of FS 55

To ensure optimal performance, it’s important to be familiar with the different sections that make up your equipment. Each individual element plays a role in how the tool functions, and understanding their interactions can help in maintaining and troubleshooting the machine effectively.

Main Assembly Elements

The central body of the equipment houses several core components that work together for smooth operation. From the motor to the handles, each section is designed for a specific purpose, contributing to the overall efficiency of the tool. Recognizing these elements helps in managing their upkeep and addressing any performance issues that may arise.

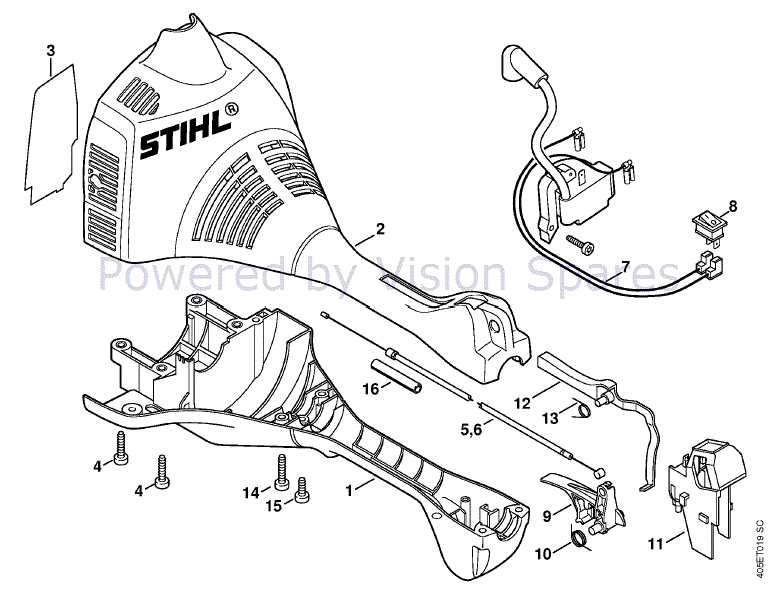

Secondary Components and Accessories

In addition to the primary mechanisms, there are various smaller accessories that enhance functionality. These include attachments and safety features that protect both the user and the tool itself. Understanding how these elements interact with the main system allows for a more informed approach to maintenance and repairs, helping extend the lifespan of the equipment.

How to Use the Parts Diagram

Having a detailed visual guide is an essential tool for understanding the setup of your equipment. It provides a clear representation of the individual sections, helping you locate and identify each component. With the right resource, maintenance tasks, repairs, or upgrades become much simpler and more accurate.

Identifying Components

By referring to the visual guide, you can easily spot where each element is located and what its function is. This makes it much easier to recognize any damaged or worn parts that need attention. Recognizing individual pieces ensures you don’t miss crucial steps during maintenance or repairs.

Efficient Repairs and Replacements

Once you’ve identified the faulty part, the next step is to find a suitable replacement. The guide offers a clear map of where each piece fits, helping you select the correct component. Using this resource effectively ensures quick and accurate repairs, reducing downtime and improving the overall lifespan of your equipment.