Every craft enthusiast knows the importance of knowing their tools inside and out. Familiarity with the key elements that make up a machine ensures smoother operation and better results. Understanding how all the components interact can help prevent malfunctions and allow for timely maintenance.

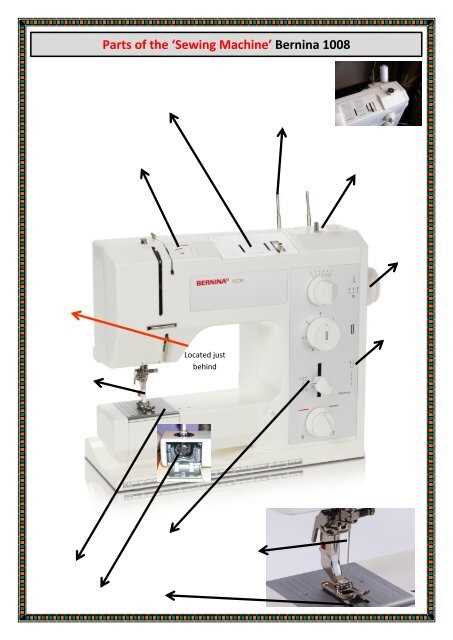

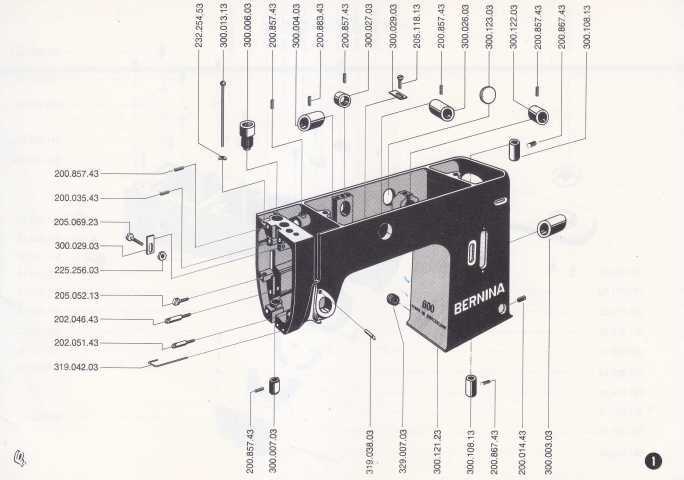

When something goes wrong, it’s essential to identify the specific parts responsible. A well-structured visual representation can be an invaluable resource. It not only provides clarity but also gives you the confidence to tackle repairs independently or with minimal assistance.

In this guide, we’ll break down the essential features of your tool, offering clear insights into each section. By the end, you’ll be better equipped to recognize the function of various components, troubleshoot issues, and keep your equipment in optimal condition for years to come.

Understanding the Components of Bernina Machines

Knowing the fundamental elements of your device is crucial for its long-term functionality. Each tool is made up of several interconnected sections, and understanding their roles is the first step toward troubleshooting, maintenance, and ensuring smooth performance. From the essential driving mechanism to the small but crucial accessories, each part plays a significant role in its overall operation.

Every section has a specific function, and when they work together in harmony, the entire system operates efficiently. Recognizing where each component fits and how it contributes to the workflow can make repairs much simpler and prevent unnecessary damage. With a better grasp of your tool’s inner workings, you’ll be able to spot issues before they become problems and keep everything running smoothly.

This guide will help you explore these key sections, breaking them down into understandable pieces. By gaining a clear understanding of how each element works, you’ll not only improve your workflow but also ensure that your equipment remains reliable for years to come.

How to Identify Bernina Sewing Parts

Properly identifying the components of your tool is essential for maintaining optimal performance and ensuring smooth operation. Knowing each part’s function helps in quickly diagnosing issues and finding solutions. With a clear understanding of each section, you can easily distinguish between different elements and know which ones require attention.

To begin, it’s important to familiarize yourself with the most commonly used sections. Each one typically has a distinct shape or feature that sets it apart. Pay attention to the placement and function of each piece. Some may be more visible, while others are hidden within the structure, but all play a role in the device’s operation.

Using reference guides and visual aids can be highly effective in this process. Diagrams or photos can help you match each element with its function, allowing for a deeper understanding and confidence when identifying components in real-life situations. This knowledge not only simplifies the repair process but also ensures you’re using your equipment to its full potential.

Tips for Maintaining Your Bernina Sewing Machine

Regular care is key to ensuring the longevity and optimal performance of your tool. Routine maintenance helps prevent common issues and ensures that all components continue to function smoothly. By taking a few proactive steps, you can extend the life of your equipment and avoid costly repairs.

Start by keeping all elements clean and free from dust, debris, or thread buildup. A clean workspace and regular inspections can go a long way in preventing malfunctions. Make sure to check for any loose or worn-out parts, and replace them as necessary to maintain smooth operation.

Lubricating moving parts is another important step. Ensuring that everything is properly oiled will help prevent friction and wear. Follow the manufacturer’s instructions for proper lubrication intervals and types of oil to use. Additionally, always store your tool in a safe, dry place to avoid exposure to extreme temperatures or humidity that could cause damage.