Every complex machine consists of multiple elements, each playing a specific role in ensuring smooth operation. Understanding how these parts interconnect and function is crucial for efficient maintenance and troubleshooting. This guide will provide an overview of key components and how they work together within a larger system.

Identifying Core Components

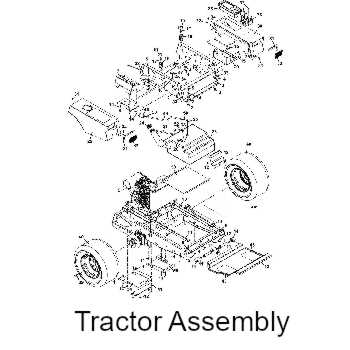

The primary elements in any mechanical setup are responsible for the system’s overall functionality. Each part serves a distinct purpose, whether it is for movement, control, or energy transfer. Recognizing these parts and knowing their positions within the system is the first step in effective maintenance.

Critical Elements for Proper Functioning

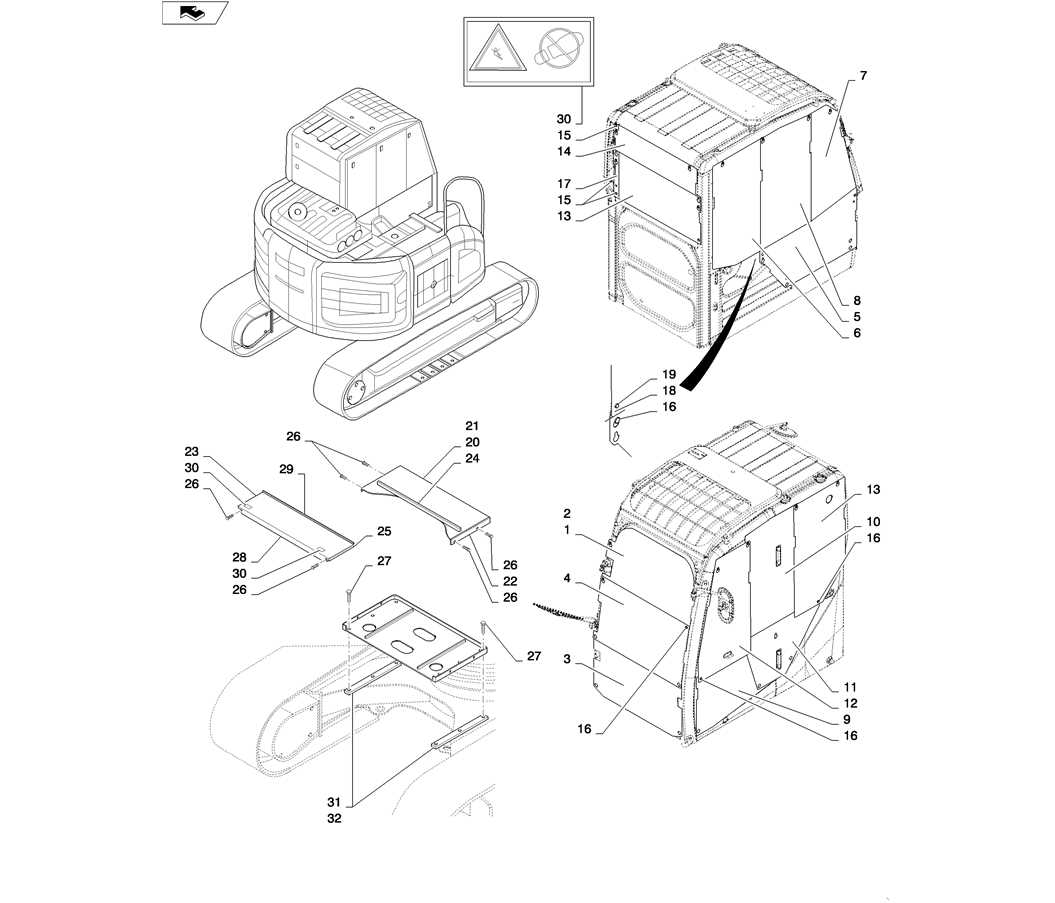

- Structural Framework: Provides the foundation and support for all other components.

- Energy Source: Powers the system, often through a fuel or electrical mechanism.

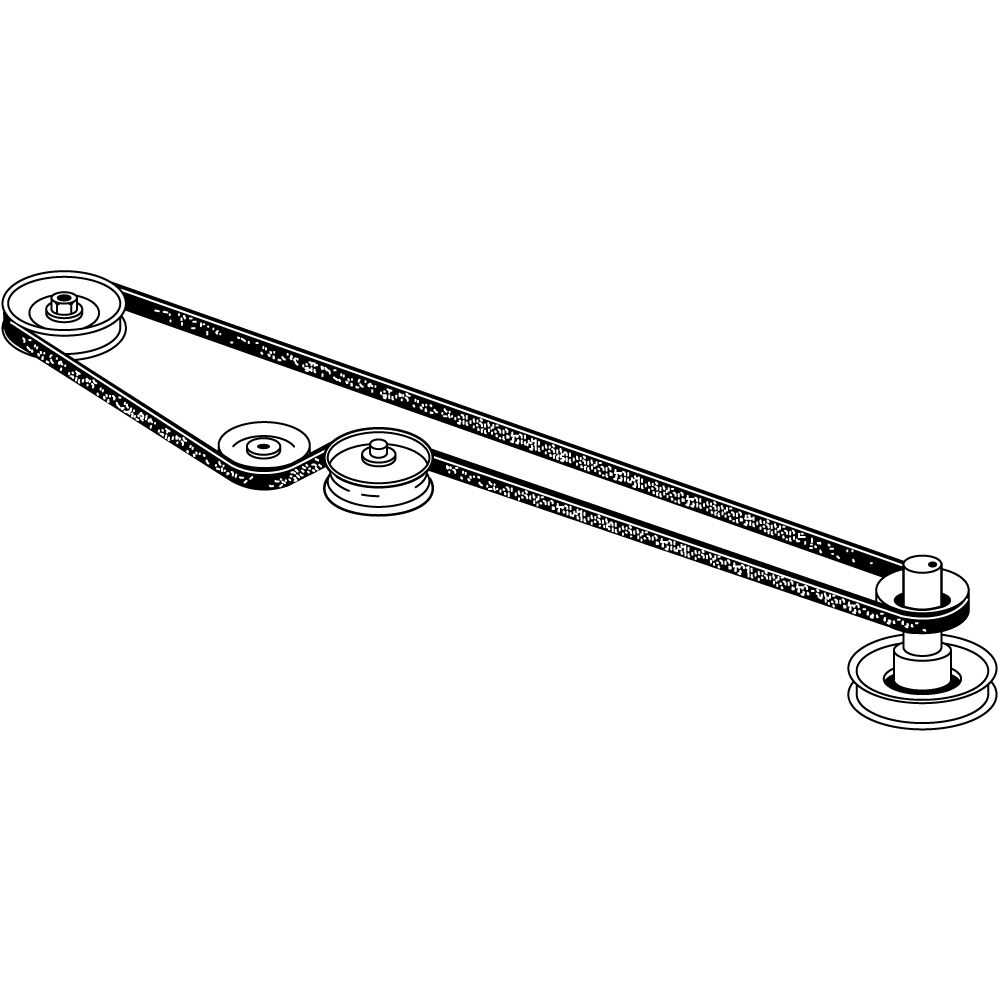

- Transmission Units: Transmit power to different parts of the system for movement and operation.

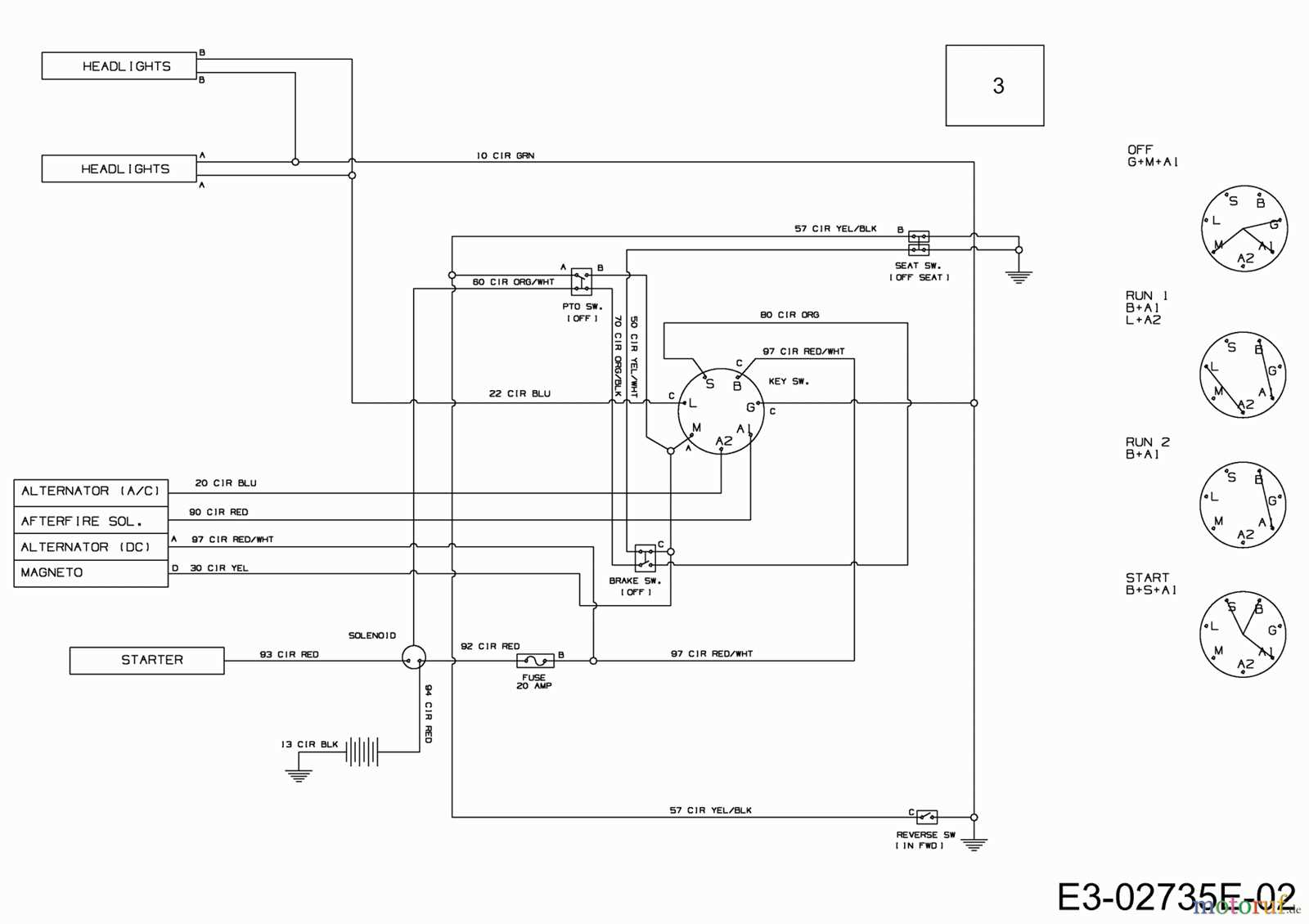

Understanding Connections Between Parts

Understanding how each element connects and interacts with the others is essential for diagnostics. Proper alignment and the correct functioning of these connections are necessary to ensure the system operates seamlessly. Misalignments or wear and tear can lead to failures.

Common Problems and Solutions

Over time, systems experience wear and tear, which can lead to inefficiencies or breakdowns. Regular inspection and understanding of the system’s structure allow for early detection of issues.

- Loose Connections: Ensure all parts are properly fastened and tightened to prevent malfunctions.

- Worn-Out Components: Regular replacement of aging parts can extend the system’s life and improve performance.

- Improper Alignment: Check that all components are aligned correctly for smooth operation.

By understanding the overall structure and how each element functions within the larger setup, users can ensure better maintenance, early detection of issues, and extend the longevity of the equipment.

Understanding the System Layout and Key Elements

Every complex mechanism consists of several interconnected elements that function together to achieve a specific purpose. By comprehending the overall layout and knowing the role of each component, users can effectively maintain the system and resolve issues when they arise. This section will explore the main elements, guide you on how to interpret the system’s structure, and provide insights into common problems and their solutions.

Key Elements in the Setup

In any mechanical setup, identifying the critical elements is essential for proper functioning. These include the structural supports, control systems, and power transmission components. Each element has a vital role in ensuring smooth operation, and understanding their positions within the system is fundamental for effective troubleshooting and repair.

How to Read the System Breakdown

Understanding how each element is represented and how they interrelate in a comprehensive diagram is key for accurate diagnostics. A well-organized breakdown makes it easier to identify which component is responsible for any malfunction or wear. Knowing how to read these representations ensures users can address issues quickly and efficiently.

Step-by-Step Guide to Identifying Components

By following a clear, step-by-step approach, it becomes easier to recognize each individual element and its purpose. Begin by locating the primary components, then move to the auxiliary parts that support or interact with them. Pay attention to connections and markings that indicate critical functions or potential weak points that may require attention.

Common Problems and Solutions

As with any mechanical system, wear and tear can lead to common issues. Regular checks and an understanding of the system’s layout help identify problems early. For instance, improper alignments or damaged supports often lead to inefficient operation. Knowing how to address these issues promptly can help avoid major malfunctions and extend the life of the system.