Maintaining your garden tools is essential for keeping them running smoothly and extending their lifespan. Understanding how different components fit together and function can save time and effort when something goes wrong. Whether you’re replacing a worn-out piece or troubleshooting a malfunction, knowing what parts are involved will help you make informed decisions about repairs and maintenance.

Proper identification of each element in your trimming equipment ensures you can quickly locate the problem and replace the necessary components. Familiarizing yourself with the internal structure and external attachments is a great first step to keep your device in top condition. This guide offers clear insight into the crucial elements and procedures for fixing common issues.

Once you understand how all the parts interact, maintenance becomes less intimidating. With a solid grasp of the layout and function of key components, you’ll be equipped to handle minor repairs and avoid costly professional services. Explore our comprehensive overview to gain the knowledge you need to keep your tool performing at its best.

Understanding the Weed Eater PE550 Parts

Every trimming tool consists of various components, each serving a specific function to ensure smooth operation. Recognizing how these individual elements work together can make troubleshooting and maintenance much easier. By examining the device’s internal and external features, users can quickly pinpoint areas that need attention or repair.

At the core of your device lies a powerful motor that drives the cutting mechanism, while other smaller elements, such as springs, shafts, and casings, contribute to its overall functionality. Understanding how each part interacts helps in the proper assembly and disassembly of the tool, ensuring you can maintain it effectively over time.

Some components, such as the handle and trigger, are essential for controlling the device, while others, like the cutting head, directly impact performance. Learning how to identify and replace these parts will keep your tool in optimal working condition, whether you’re performing routine maintenance or addressing a specific issue.

Common Issues and Replacement Parts

Even the best trimming tools can experience problems over time. Understanding the common issues that arise and knowing which components need replacement can save both time and money. Regular maintenance can prevent major malfunctions, but certain parts may wear out and require periodic replacement to ensure continued efficiency.

Motor and Performance Problems

One of the most common issues is a malfunctioning motor. If the device struggles to start or loses power during use, the motor may be damaged or worn out. In such cases, replacing the motor or its internal components, like brushes or bearings, could resolve the issue and restore the tool’s performance.

Cutting Mechanism Failures

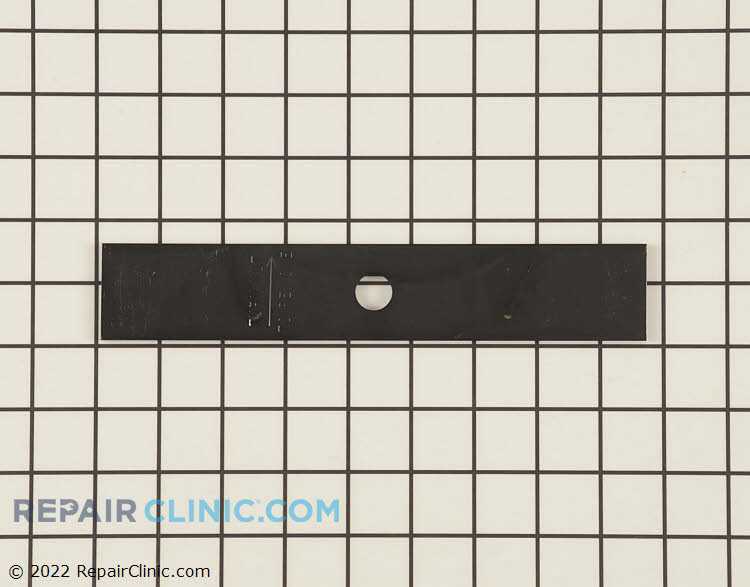

The cutting head is another part that commonly needs attention. It may become clogged, misaligned, or worn out, which can reduce cutting efficiency. Replacing the blade or adjusting the alignment often solves this issue, ensuring clean and efficient cutting every time.

Step-by-Step Guide for Assembly

Assembling your trimming tool can seem challenging at first, but following a clear and systematic approach makes the process straightforward. Ensuring all components are correctly fitted together is key to achieving optimal performance and safety. This guide provides a step-by-step approach to assembling your device, from the motor to the cutting mechanism.

Start by carefully examining all the components and identifying the main parts. Begin the assembly with the handle, securing it tightly to the main body. Next, attach the motor to the frame, ensuring it is aligned properly. Once the motor is secured, move on to installing the cutting head, making sure it is firmly connected and rotates freely.

Finally, check all connections for stability and make sure all fasteners are tightly in place. Test the tool briefly to ensure that everything is functioning properly before use. Following this process ensures your equipment is assembled correctly and ready for efficient operation.