Maintaining a lawn care machine requires understanding its core elements and their functions. Knowing how each component contributes to the overall performance ensures proper care and efficient operation.

In this guide, we will explore how to identify various key components and offer practical advice for upkeep. Regular maintenance prevents wear and tear, extending the machine’s lifespan and ensuring it runs smoothly.

We will also delve into the importance of each part, focusing on easy-to-follow steps for maintenance and replacement, helping you keep the equipment in optimal condition for long-term use. Proper attention to detail can make a significant difference in overall functionality.

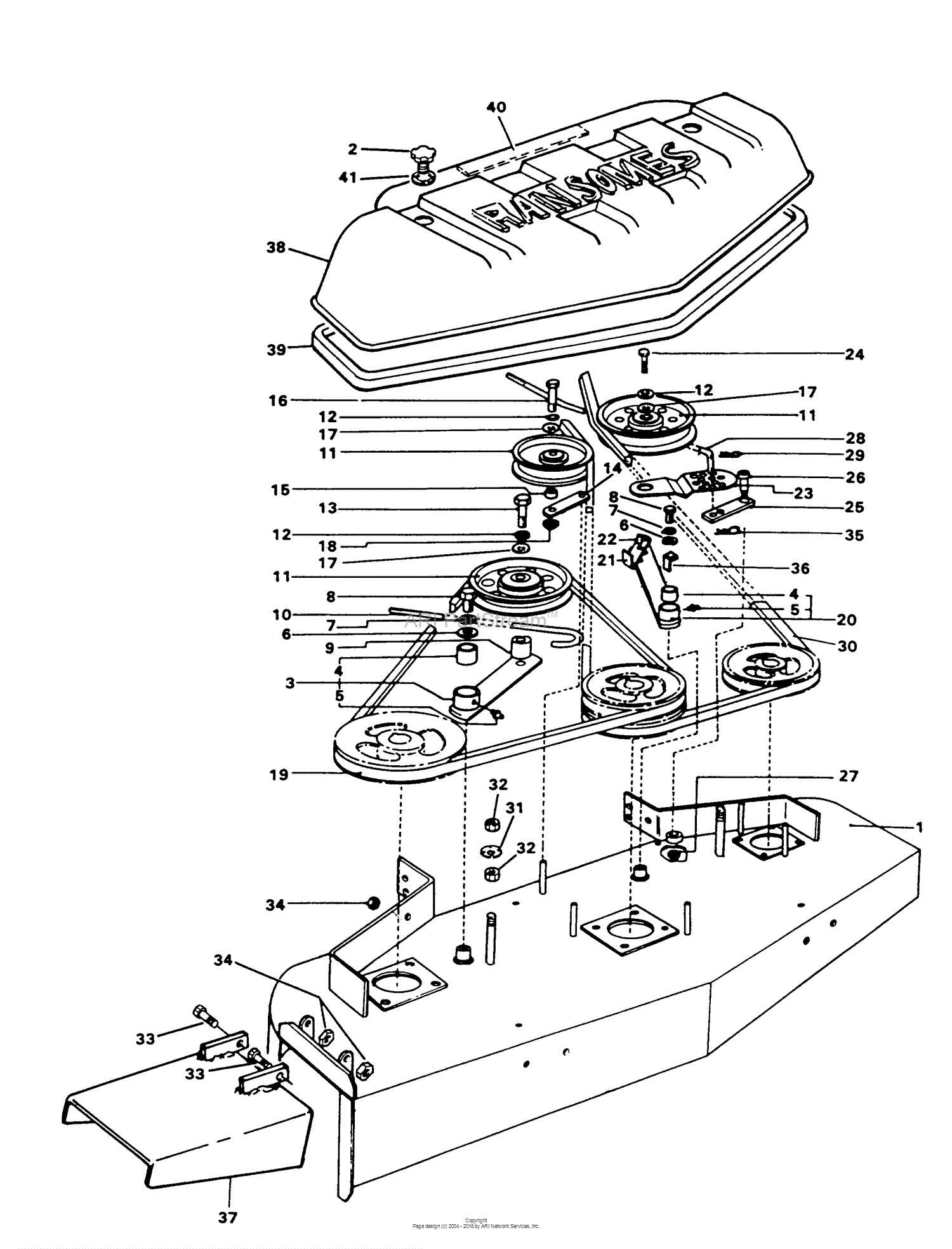

Understanding Essential Components

To ensure efficient operation and longevity of your equipment, it’s crucial to understand the various elements that contribute to its functionality. Each component has a specific role that directly impacts overall performance. Familiarity with these elements allows for better maintenance and troubleshooting, helping users address issues quickly and keep the machine running smoothly.

Main Structural Elements

The main structure of the equipment provides the foundation for all other components. It holds everything in place, ensuring that moving parts operate within their designed parameters. Understanding how the frame interacts with other elements will give you insight into potential areas that require regular inspection or repair.

Functional and Movable Components

Several parts are responsible for the operational tasks, from generating power to propelling the system forward. These moving parts must work in sync to achieve optimal performance. Knowing how each piece functions can guide you in troubleshooting any operational issues and help maintain a steady, efficient operation.

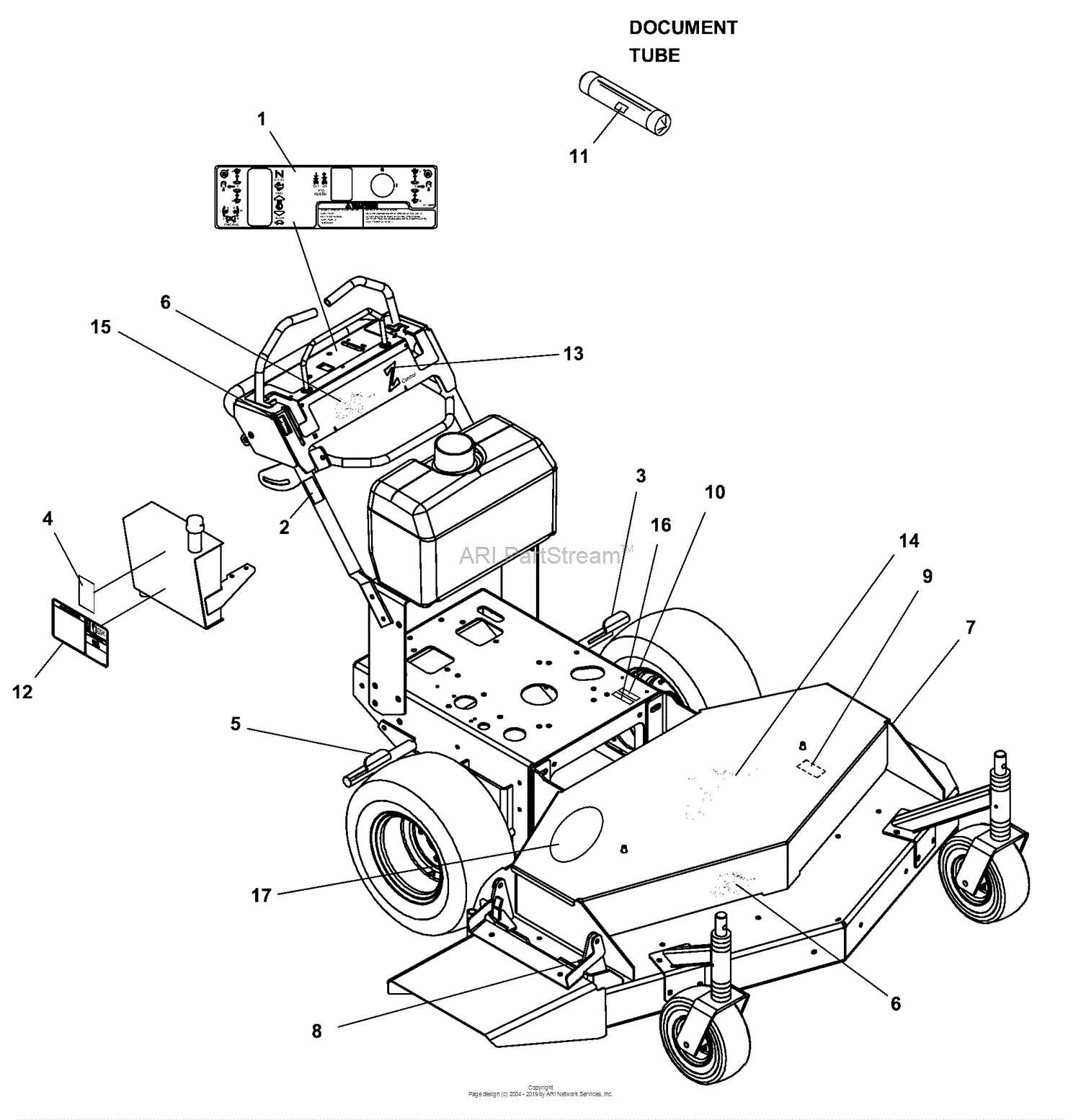

How to Identify Key Components

Recognizing the crucial elements of your equipment is the first step in proper maintenance. By understanding the primary functions and locations of each component, you can effectively troubleshoot issues and perform essential upkeep tasks. Identification of these parts is key to ensuring that everything is in working order.

Start by locating the main operational units, which are typically visible and easy to access. These components play a vital role in the overall performance and can be easily examined for wear or damage. Checking for any irregularities in movement or appearance can often point you in the right direction when diagnosing problems.

Next, familiarize yourself with smaller, less visible parts that may require occasional attention. Although they may not be directly responsible for motion, they support other parts and ensure smooth operation. Regular inspection of these secondary components helps maintain the efficiency of the entire system.

Maintenance Tips for Essential Components

Proper upkeep is essential to keep your equipment running smoothly and to prevent unnecessary repairs. Regular maintenance not only extends the lifespan of the machine but also ensures peak performance throughout its use. Consistent care can help avoid major issues and reduce downtime.

Start by cleaning the key functional parts after every use. Dirt and debris can cause friction and wear, leading to damage over time. Removing any buildup helps maintain efficiency and prevents malfunctions. Be sure to inspect the moving elements for signs of wear, as they are the most likely to experience stress during operation.

Lubrication is another vital aspect of maintenance. Regularly apply the appropriate lubricant to the moving parts to minimize friction and ensure smooth operation. Neglecting lubrication can lead to overheating and accelerated wear. Lastly, replace any worn or damaged components promptly to prevent further damage to the system.