Maintaining equipment in optimal condition requires a clear understanding of its components and how they work together. By having a visual reference of all key parts, users can quickly identify which elements need attention or replacement. This guide aims to provide an overview of how to effectively use component breakdowns for better tool upkeep.

Knowing the different parts and their functions can significantly simplify repair tasks and prevent unnecessary downtime. Whether you are a seasoned technician or a DIY enthusiast, understanding how to read and utilize these illustrations will make maintenance easier and more efficient. Proper knowledge of your tools ensures longer life and reliable performance.

Familiarizing yourself with every part’s role allows you to troubleshoot and fix issues faster. This section will explain how to navigate the visuals and pinpoint the parts that matter most when tackling repairs or replacements.

Understanding the Tool Breakdown

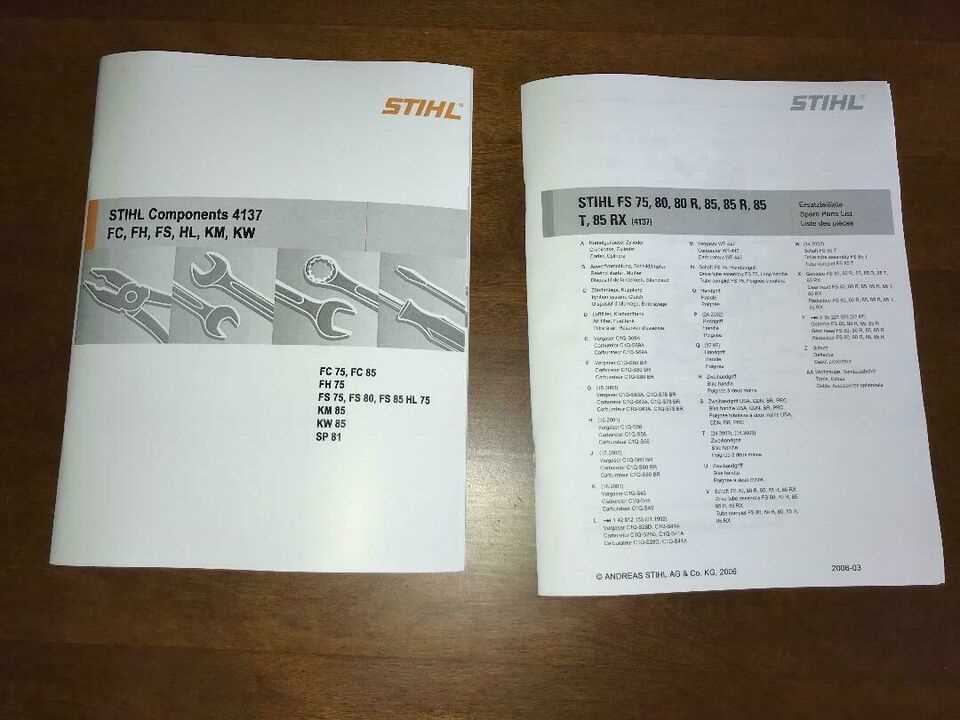

Having a clear visual representation of the internal components of your equipment is essential for proper maintenance. These detailed visuals provide an overview of each crucial element and how they interact, which allows users to quickly diagnose problems and determine necessary repairs. Understanding the layout of the components enables more efficient troubleshooting and part replacements, keeping your tool in peak working condition.

How to Read the Breakdown

The visual representation typically shows the full assembly, with each section labeled to indicate the specific components involved. By identifying the part names and their locations, users can pinpoint where issues may arise or which parts need attention. This method also allows for easier reassembly after maintenance tasks, ensuring everything is correctly fitted.

Benefits of Knowing the Layout

Familiarity with the equipment layout reduces the risk of making mistakes during repairs and helps in managing spare parts efficiently. When you know which parts are interconnected, you can avoid unnecessary disassembly, saving time and reducing the risk of damaging other components. Moreover, understanding the layout helps in making informed decisions when replacing worn-out elements.

How to Use the Breakdown for Repairs

Using a detailed component illustration is an essential step in performing effective repairs. It acts as a guide, helping you locate, identify, and assess each part of your tool. With a clear reference in hand, the process of disassembling, replacing, or fixing any broken parts becomes much more straightforward and organized.

Step-by-Step Repair Process

To begin, study the illustration carefully, ensuring you understand the location and connection of each part. This will help you plan the repair process efficiently. Once the faulty components are identified, proceed with removing or replacing them by following the correct steps, ensuring that the tool is reassembled properly afterward. The visual guide ensures that no part is overlooked and helps in placing everything back in its correct position.

Ensuring Correct Reassembly

After completing the repairs, refer back to the visual reference to make sure that all components are correctly reassembled. This step is crucial to avoid missing any small but vital parts that could affect the tool’s performance. By double-checking the placement of each component, you ensure that the tool will function as intended once the repair is complete.

Common Issues and Tool Component Replacement

When using outdoor equipment, it’s common to encounter various issues that may hinder its performance. Understanding the most frequent problems and how to address them through component replacement is key to keeping the tool running smoothly. Often, regular maintenance or replacing worn parts can prevent bigger breakdowns and extend the lifespan of the equipment.

One of the most frequent issues users face is malfunctioning parts due to wear and tear, such as damaged drive mechanisms or worn-out seals. These issues can often be detected early by observing unusual noises, decreased efficiency, or visible damage. In such cases, replacing the affected components is necessary to restore functionality. Identifying the correct components and ensuring proper installation is crucial for the tool’s performance after repairs.

In addition, improper handling or neglecting routine maintenance can cause parts to loosen, break, or become ineffective. Regularly checking the condition of the components and replacing those that show signs of damage or wear will help keep the tool in optimal working condition, preventing further complications down the road.