When operating a lawn tractor, it is crucial to understand the key elements that make up its control system. These parts work together to ensure smooth and responsive movement, allowing for precise navigation across your yard. Proper knowledge of how each piece functions can help you maintain and repair your machine more effectively.

The system consists of various interconnected components, each playing a unique role. From the initial input to the final execution, every part must be in good condition to guarantee proper operation. If you notice any issues, identifying the faulty elements can save you time and effort when troubleshooting or performing repairs.

Regular maintenance and attention to detail are essential to keep the control system functioning optimally. Understanding how the system works and recognizing the signs of wear or malfunction will help you make informed decisions about repairs or replacements. Whether you’re a seasoned user or a new owner, this guide will provide you with valuable insights.

Understanding the Control System Components

In any vehicle designed for outdoor tasks, the control mechanism is vital for guiding and maneuvering. The system relies on several key components working in harmony to allow smooth turns and precise movement. Understanding these elements is essential for proper maintenance and troubleshooting, ensuring the machine operates efficiently and safely.

Main Elements of the Control Mechanism

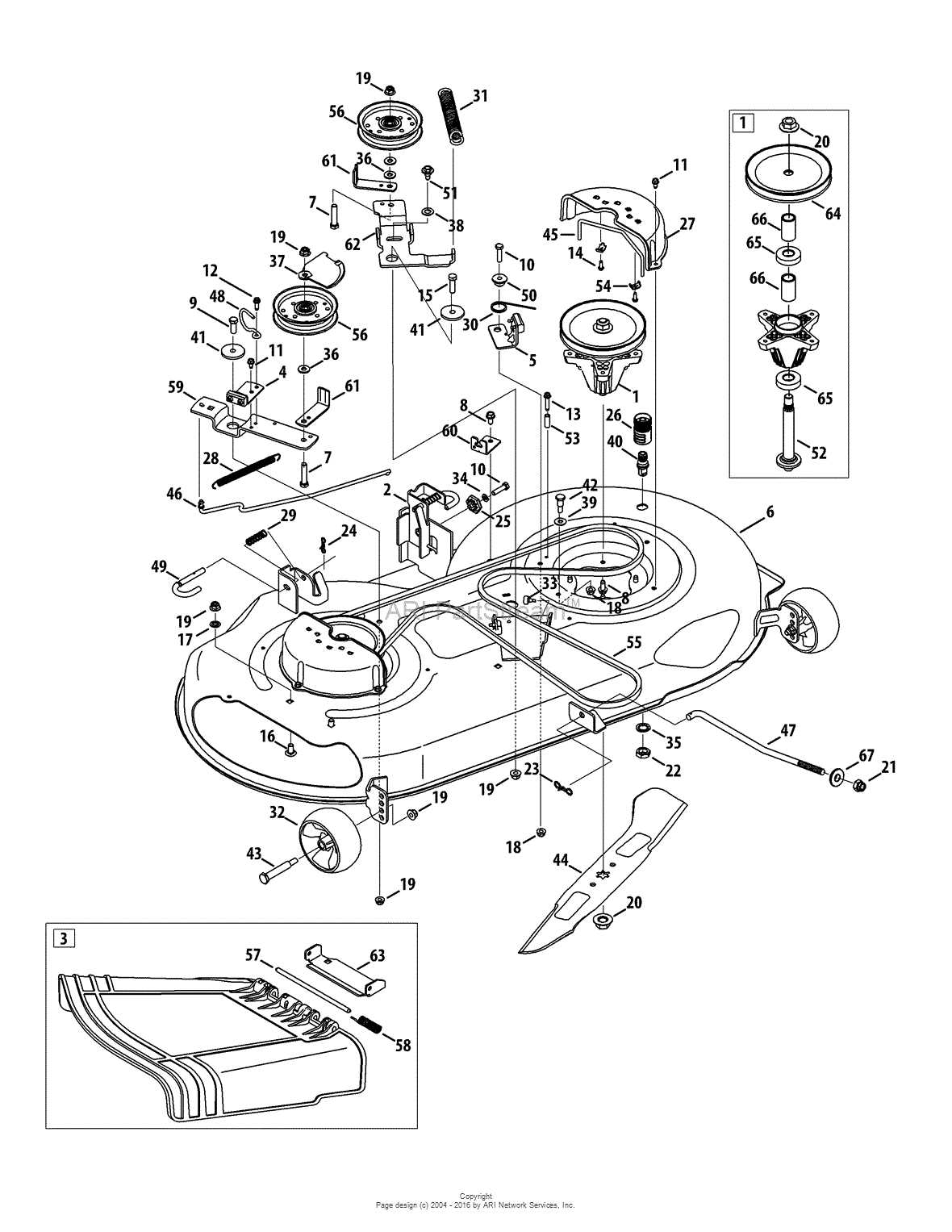

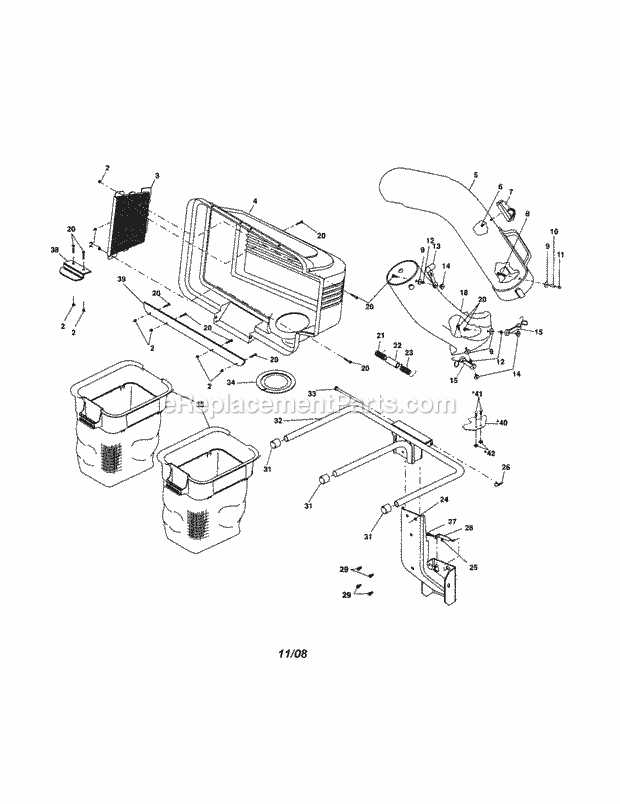

At the core of the system are the essential elements that translate user input into motion. These components include the links, pivots, and control cables, all working together to transfer force from the operator to the vehicle. Their condition plays a major role in the responsiveness and ease of operation, which is why it’s important to regularly inspect and maintain them.

Signs of Wear and Necessary Maintenance

Over time, components in the control system may experience wear and tear due to continuous use. It’s important to keep an eye out for signs of malfunction, such as difficulty turning or irregular movement. Addressing minor issues promptly can prevent more serious problems and extend the lifespan of the entire system. Regular checks and appropriate lubrication are essential steps in maintaining smooth functionality.

How to Identify Control System Components

Identifying the key components of the control system is an essential part of maintenance. Knowing where to look and what to check can help you diagnose problems early and ensure that the machine operates as intended. The system includes several different parts, each with its own specific function, which work together to provide the necessary functionality for smooth operation.

Steps to Locate and Identify Key Elements

To successfully identify the main components of the control system, follow these simple steps:

- Begin by locating the system’s main housing or frame, which typically holds most of the connecting parts.

- Inspect the control mechanism, looking for the various linkages, levers, and connecting rods.

- Check for any visible signs of wear, rust, or misalignment in these parts, as these are often indicators of where the problem lies.

- Identify the cables and their connections, ensuring they are intact and securely fastened.

Common Signs of Wear or Damage

When inspecting the system, keep an eye out for several common signs that indicate a component may be damaged or worn:

- Difficulty in turning or uneven motion when using the controls.

- Loose or detached components that may affect the smooth operation of the system.

- Excessive play or movement in the links or rods.

- Fraying or cracks in cables or connectors.

Identifying these signs early will allow you to address issues before they become major problems, ensuring the longevity and efficiency of the system.

Step-by-Step Guide to Repairing Control Mechanism

Repairing the control system of a machine requires a clear understanding of its components and a systematic approach. This guide will walk you through the process of addressing common issues, from identifying the problem to performing the necessary fixes. By following each step, you can restore smooth operation and extend the life of your equipment.

The first step in any repair is to ensure that the machine is powered off and properly secured. Once the equipment is safe to work on, you can begin the inspection and diagnosis process. Look for any signs of malfunction, such as difficulty in movement or unusual noises, and narrow down the potential causes.

Next, carefully dismantle the affected components, taking note of how they are assembled. Use appropriate tools to avoid causing further damage. After disassembling, inspect each part closely for any wear, rust, or other signs of deterioration. Replace any damaged components with compatible parts to ensure the mechanism functions correctly.

Once the repairs are complete, reassemble the components in the reverse order, ensuring all connections are secure and properly aligned. After reassembly, test the system by gently operating the controls to ensure everything moves smoothly and without resistance. If any issues persist, revisit the previous steps or consult a professional for additional assistance.