Understanding the intricate system that drives a vehicle’s motion is essential for maintaining its efficiency. The mechanism responsible for transferring power from the engine to the wheels consists of various interrelated elements, each playing a critical role in ensuring smooth operation. These components are designed to withstand high levels of stress while providing precision and reliability.

Each element within this system works together to manage the vehicle’s speed and torque. From the critical gears that adjust the rotation to smaller components that ensure seamless shifting, knowing how these parts fit together helps in troubleshooting and repairs. Maintenance becomes easier when one understands the function of each unit.

In the following sections, we will break down the essential components and their functions, helping you gain insight into how this complex system operates and how to address common issues that may arise over time.

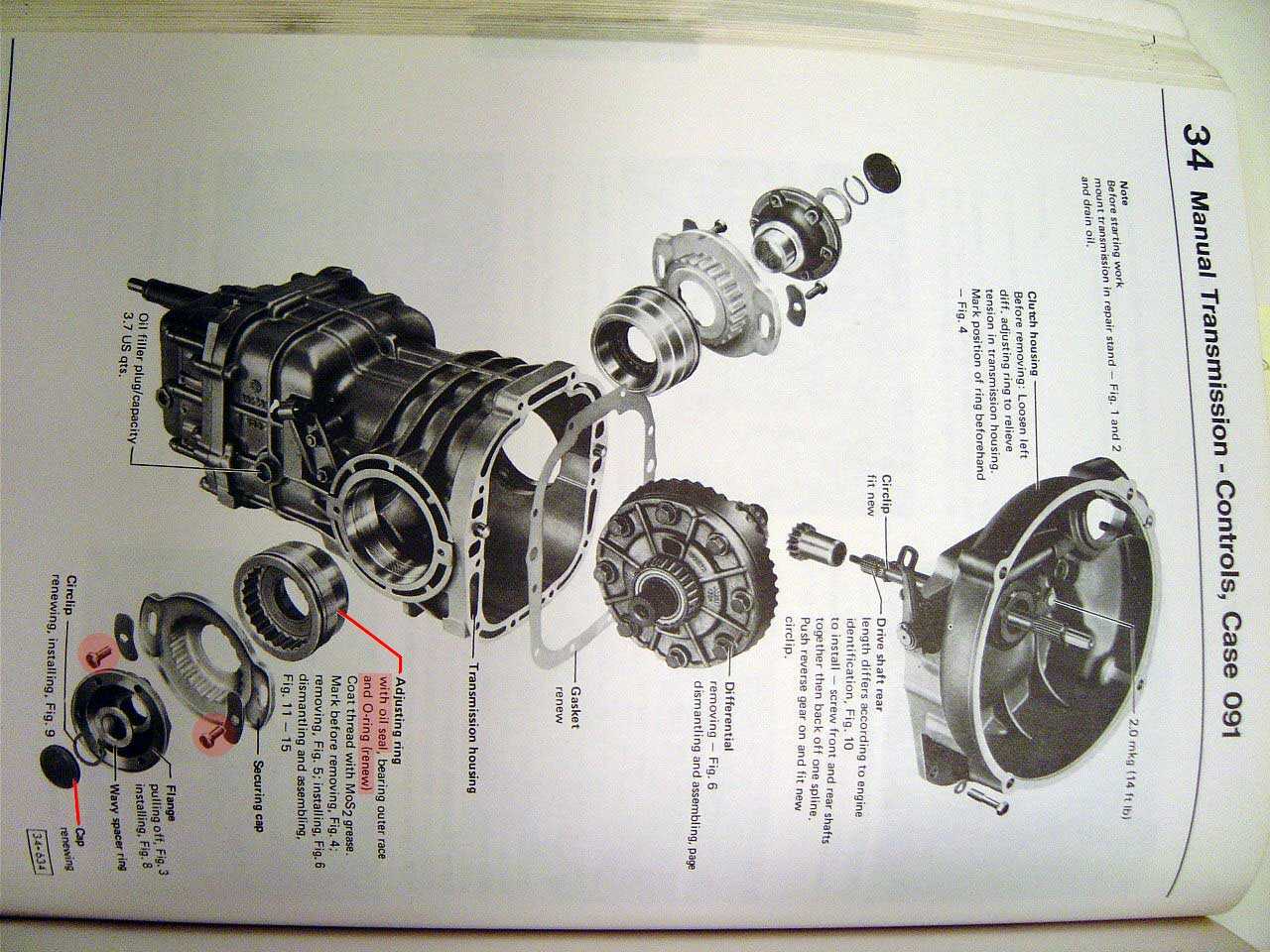

Overview of Key Mechanisms

The gear system in a Volkswagen vehicle is a complex arrangement of interconnected elements designed to manage power transfer from the engine to the wheels. These mechanisms are carefully engineered to allow for smooth acceleration, deceleration, and overall control of the vehicle. Each component plays a pivotal role in the vehicle’s efficiency and performance, ensuring that the correct amount of torque is applied at the right time.

Within this system, various critical elements work together in harmony. The gears regulate rotational speed, while other units assist in shifting, allowing for adjustments based on driving conditions. The overall structure relies on the precise interaction of these components to provide seamless operation and durability over time.

By understanding how each unit functions within the system, vehicle owners can better address maintenance needs and recognize potential issues before they become serious problems. This knowledge helps keep the vehicle running smoothly and prolongs its lifespan.

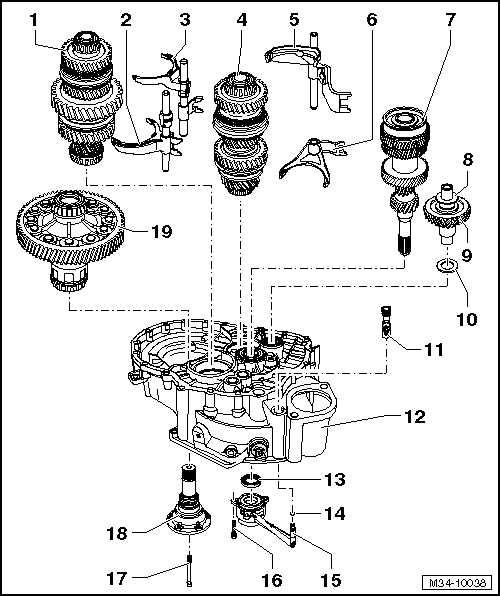

Key Elements in VW Gearbox System

The system responsible for managing power flow in a Volkswagen vehicle includes several essential components. These units are carefully designed to work together to provide efficient control over the vehicle’s speed, torque, and overall performance. Each element contributes to the seamless operation of the car, ensuring smooth shifts and reliable driving experiences under varying conditions.

Critical Components

Key elements of this mechanism include the gears, clutch, and selector mechanisms. The gears regulate the rate at which the engine’s power is transferred to the wheels, while the clutch allows for smooth engagement and disengagement during shifting. The selector system helps in choosing the appropriate gear based on driving demands, allowing for precise control over speed and efficiency.

Supporting Units

Alongside the main components, supporting units such as the flywheel and synchronizers help to maintain balance and synchronization throughout the system. These parts are integral to ensuring that the gears engage smoothly without any jarring or resistance. Together, they ensure the durability and reliability of the entire system, minimizing wear and tear over time.

Understanding the Functionality

The gearbox in a Volkswagen vehicle is designed to manage the flow of power from the engine to the wheels, adapting to different driving conditions. It ensures the vehicle operates smoothly by adjusting the vehicle’s speed and torque through a series of interconnected components. When the driver shifts gears, the system engages the appropriate elements, allowing for seamless changes in power distribution to match the required speed or driving performance.

Shifting Process and Mechanism

When a gear is selected, a mechanism engages the corresponding gearset. This action alters the ratio between engine speed and wheel speed, allowing the vehicle to either accelerate or decelerate effectively. The clutch disengages and engages the appropriate gears, ensuring that there is no sudden jolt during the shift. This coordinated process enables the vehicle to respond smoothly to driver input while maintaining engine efficiency and power balance.

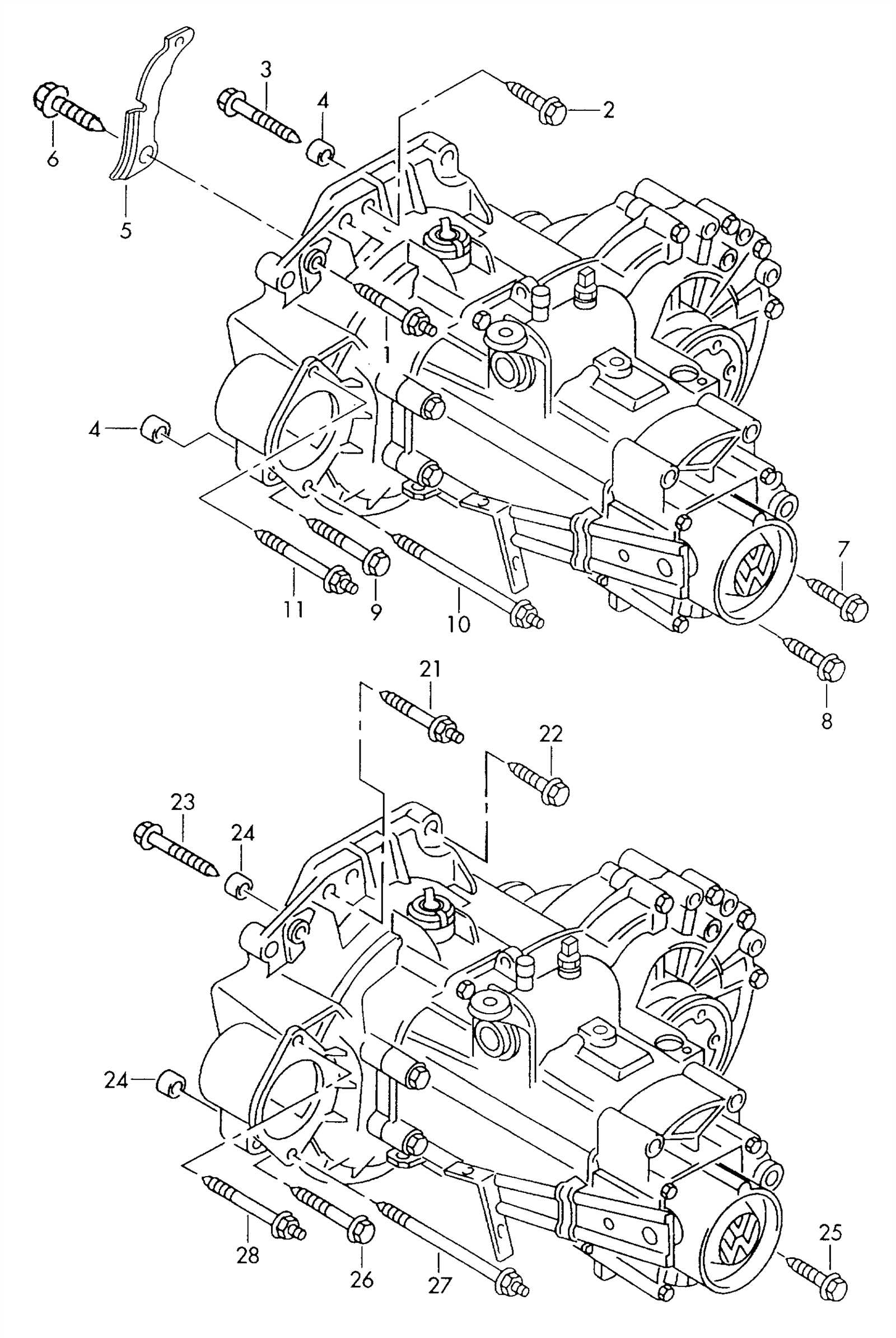

Overview of Gearbox Functions

The primary role of a gearbox system in a Volkswagen vehicle is to manage the relationship between the engine’s output and the wheels’ movement. It ensures that power is distributed efficiently to provide the necessary torque for different driving conditions. This system helps maintain vehicle performance while adapting to speed changes, load variations, and shifting demands.

Here are the key functions performed by the gearbox system:

- Power Distribution: The gearbox regulates the power transferred from the engine to the wheels, adjusting it according to the required speed and driving conditions.

- Speed Adjustment: By shifting between gears, the system allows the vehicle to operate at different speeds while maintaining optimal engine efficiency.

- Torque Management: It ensures that the engine delivers the right amount of torque to the wheels for smooth acceleration and deceleration.

- Efficient Shifting: The system enables quick and precise shifting between gears, ensuring minimal disruption to the vehicle’s movement.

These functions work together to provide a balanced driving experience, ensuring smooth transitions and better control while driving under various conditions.

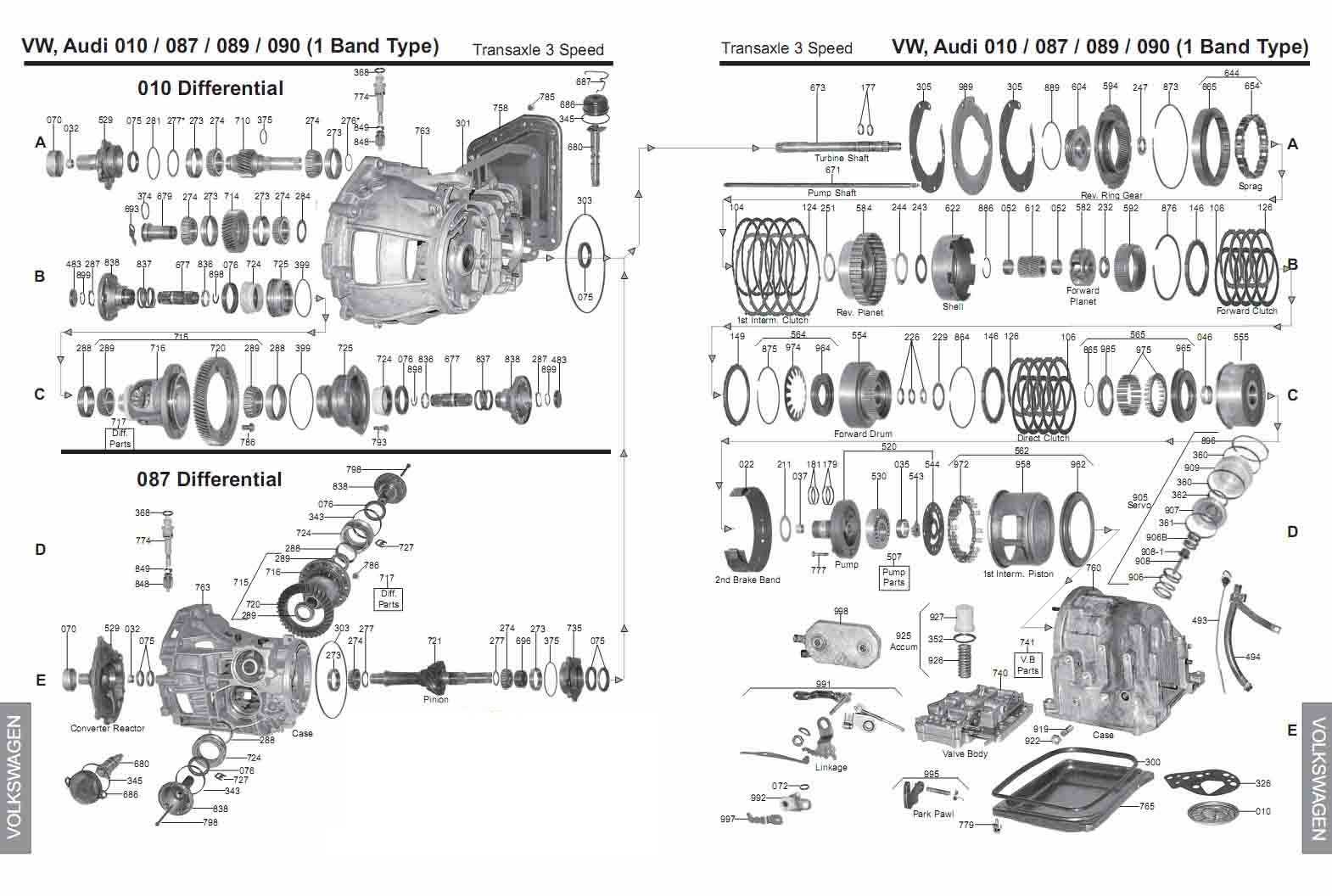

Identifying Potential Problems

Like any complex mechanical system, the gearbox in a Volkswagen vehicle can experience issues over time due to wear and tear, environmental factors, or improper maintenance. These issues can affect the vehicle’s performance, causing rough shifts, noises, or even complete failure if not addressed promptly. Understanding the most common problems can help in diagnosing and resolving them before they escalate.

Frequent Concerns

- Rough Shifting: Hard or jerky shifts can indicate issues with the clutch or gear synchronizers, leading to difficulty in engaging gears smoothly.

- Slipping Gears: If the vehicle unexpectedly slips out of gear, it could point to a problem with the clutch or internal components, causing a loss of power.

- Unusual Noises: Grinding or whining sounds during shifting can suggest worn-out gears or bearings, signaling the need for inspection and repair.

- Fluid Leaks: Low fluid levels or leaks may result in overheating and cause poor performance. Regular checks are essential to ensure the system remains properly lubricated.

- Delayed Shifting: A noticeable delay when shifting gears may indicate issues with the gear selectors or control systems, which can disrupt the smooth operation of the vehicle.

Recognizing these issues early allows for timely maintenance, helping to preserve the longevity and efficiency of the gearbox system. Regular checks and proper care are key to avoiding costly repairs and ensuring optimal performance.

Diagnosing Gearbox Problems

Identifying issues within a gearbox system requires careful attention to symptoms and understanding how the system operates. A variety of factors can cause malfunction, from mechanical wear to fluid issues. Proper diagnosis is crucial for addressing problems before they lead to more severe damage and costly repairs.

Common Symptoms

There are several warning signs that can indicate issues with the gearbox. These include difficulty shifting gears, slipping out of gear, unusual noises, or fluid leaks. Each of these symptoms points to a different potential problem within the system. For example, rough shifting may suggest worn synchronizers, while slipping gears may be related to problems with the clutch or internal components.

Steps for Accurate Diagnosis

To properly diagnose issues, it’s important to first check the fluid levels and condition. Low or dirty fluid can cause improper functioning. Additionally, listening for unusual noises while shifting or while the vehicle is in motion can help pinpoint mechanical problems. Finally, a professional inspection of the internal components may be necessary for more complex issues such as worn gears or damaged bearings.