When working with small, single-cylinder motors, it is crucial to understand the internal layout and functioning of their key components. A thorough knowledge of these mechanical parts can significantly improve maintenance, troubleshooting, and repairs. This guide will help you familiarize yourself with the essential elements that make up the core of such systems, enabling you to carry out more effective upkeep and resolve common issues.

Familiarizing yourself with the system’s layout is the first step toward ensuring its longevity. The individual components work in unison, and each piece has a specific role in the overall operation. By reviewing how they fit together and interact, you’ll gain a deeper understanding of how to identify problems and replace worn-out elements with precision.

In addition to simply knowing the names of the parts, recognizing their functions is key. Many malfunctions can be traced to specific components, so knowing what each part does will save time and effort in the repair process. Whether you are a hobbyist or a professional mechanic, this knowledge is invaluable in keeping small engines running smoothly.

Understanding the Small Engine Components

To ensure the smooth functioning of any small motor, it’s important to comprehend how the various internal elements work together. Each component plays a unique role in the system, contributing to the overall efficiency and performance. Gaining insight into these pieces and their interactions is essential for effective maintenance and repair.

Key components in a small motor are designed to perform specific functions, such as generating power, transferring energy, and controlling various mechanical processes. These pieces interact in a highly coordinated manner, and even minor malfunctions can lead to significant performance issues.

Here are the primary components that you should be familiar with:

- Cylinder – The heart of the motor, where combustion takes place.

- Piston – Moves up and down within the cylinder, transferring energy.

- Crankshaft – Converts the linear motion of the piston into rotational motion.

- Valves – Regulate the intake of air and exhaust of gases.

- Timing Chain or Belt – Ensures that the piston and valves operate in sync.

- Ignition Coil – Creates the electrical spark needed to ignite the fuel.

Each of these parts works together to ensure the motor operates effectively. Recognizing the function of each piece and understanding their interconnections will allow you to diagnose problems and make more informed decisions during repairs.

Moreover, regular inspection of these components can prevent serious issues down the road. Over time, certain parts can wear down or become misaligned, which can result in reduced performance. By monitoring their condition and making adjustments when necessary, you can extend the life of your small motor and maintain its efficiency.

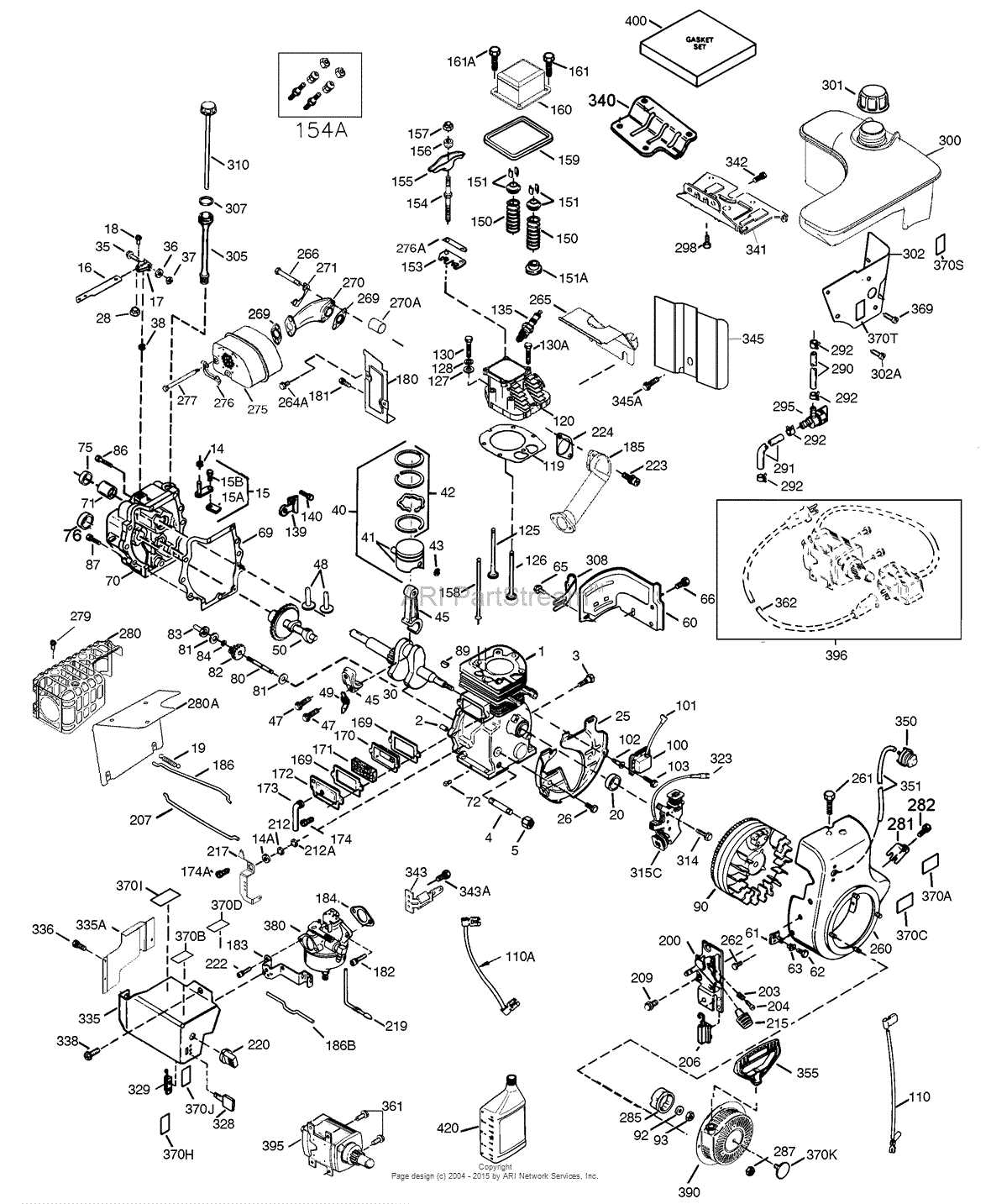

How to Identify Parts in the Engine Layout

Understanding how to identify the various components in an engine schematic is essential for anyone looking to perform maintenance or repairs. Recognizing each piece’s shape, size, and function allows you to make informed decisions and address issues efficiently. This section will help you navigate through the layout and identify the key parts in the motor system.

Start with the Main Components

The first step in identifying parts is focusing on the major components that serve as the foundation of the motor’s operation. These are usually the largest and most central pieces in the layout, such as the combustion chamber, the crankshaft, and the piston. These parts are typically represented prominently in most schematics and are easy to locate due to their size and central role in the system’s function.

Focus on Supporting Elements

Once the main components are identified, the next step is to focus on the smaller, supporting elements that help facilitate the overall functioning of the motor. These can include items like the timing belt, valves, and ignition coil. These parts are often arranged around the central components and may require a bit more attention to spot, especially if they are smaller or more intricate.

When reading an engine layout, it’s also important to pay attention to any labels or annotations that describe each component. Many diagrams will provide brief descriptions or part numbers next to the elements, which can help confirm your identification. With enough practice, you’ll be able to quickly locate and recognize all the essential components in any motor schematic.

Common Issues and Repairs for Small Motors

Like any mechanical system, small motors are prone to wear and tear over time. Regular use, exposure to harsh conditions, and insufficient maintenance can all contribute to a variety of issues. Identifying and addressing these problems early is crucial to ensuring the motor runs smoothly and lasts longer. This section will cover some of the most common issues and the repairs that can resolve them.

Frequent Issues

One of the most common problems with small motors is a lack of power or difficulty starting. This can be caused by several factors, including:

- Worn-out spark plugs, which fail to generate a strong spark for ignition.

- Fuel system clogs, preventing proper fuel flow to the combustion chamber.

- Air filter blockages, restricting airflow and affecting combustion efficiency.

- Faulty ignition coils, which can cause misfiring or no spark at all.

Another frequent issue is overheating. This can occur due to insufficient cooling, poor oil circulation, or a blocked exhaust system. Overheating can lead to engine damage if not addressed promptly, so it’s important to monitor the temperature and ensure the cooling system is functioning properly.

Repairs and Solutions

Repairs for these issues vary depending on the specific problem. For ignition-related issues, replacing spark plugs and inspecting the ignition coil for damage is often necessary. Fuel-related issues can typically be resolved by cleaning or replacing the fuel filter and ensuring the carburetor is properly tuned.

Overheating can often be prevented or fixed by checking and replacing the oil, cleaning the cooling fins, and ensuring the exhaust is clear of debris. Regular maintenance, such as cleaning the air filter and changing the oil, will help prevent many of these common problems and keep the motor running efficiently.

By understanding these typical issues and learning how to fix them, you can extend the lifespan of your motor and avoid costly repairs down the road.