When working with mechanical equipment, understanding its internal structure is key to proper usage and maintenance. Each machine is made up of various components that work together to ensure smooth operation. Knowing how to recognize and interpret these components can prevent issues and help with repairs.

Key Elements of a Mechanical System

Machines are often made up of multiple integral elements, each serving a specific function. These elements are usually connected in such a way that they operate together seamlessly. Recognizing these components is the first step in troubleshooting and maintenance.

Recognizing Common Components

- Motor: The driving force behind the system’s movement.

- Housing: The external structure that protects internal parts.

- Bearings: Essential for reducing friction and allowing smooth motion.

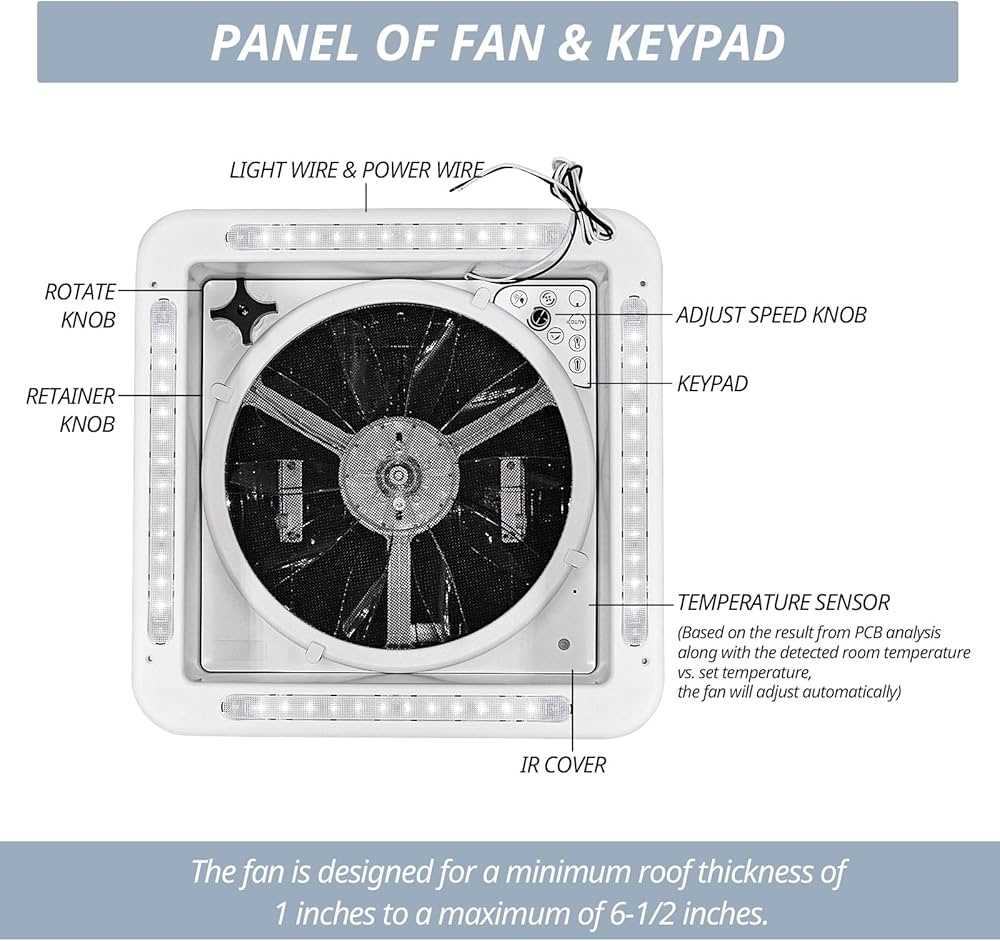

How to Interpret the Internal Layout

To effectively use any machine, it’s crucial to understand the configuration of its inner components. This layout shows the relationship between various parts and helps guide proper maintenance and repair procedures. A visual guide is often the most effective tool for learning this structure.

Maintaining Optimal Function

Once you are familiar with the machine’s internal layout, regular care is essential to ensure its long-term performance. Regular checks and cleaning can help prevent breakdowns and ensure all components continue to function properly.

Maintenance Tips

- Regular Inspection: Check all moving parts and connections frequently.

- Lubrication: Ensure that moving elements are well lubricated to reduce wear.

- Cleaning: Remove dust and debris to avoid clogging or overheating.

Understanding the Internal Layout

Identifying Key Components Inside the Equipment

How to Interpret System Layouts

Step-by-Step Guide to Reading the Configuration

Essential Tips for Caring for the Internal Mechanisms

Recognizing the intricate arrangement of a machine’s internal components is vital for its efficient operation and maintenance. Familiarity with the configuration allows for effective troubleshooting, repairs, and optimizations. This section provides insight into understanding, interpreting, and caring for a machine’s internal structure.

Identifying Essential Internal Elements

The first step in working with any mechanical system is to identify its primary components. Each element plays a unique role, contributing to the overall function of the machine. These include the energy source, moving elements, and the outer housing, all of which must be properly maintained to avoid malfunction.

How to Interpret the System Layout

Understanding the layout of a machine’s components is crucial. Each element is connected in a specific way that allows for smooth operation. By reading a system layout effectively, you can identify how parts interact and how to properly care for them.

Step-by-Step Approach to Reading the Configuration

Start by familiarizing yourself with the overall system. Then, break down the diagram into individual sections, focusing on the key components and their connections. Understanding how energy flows through the system and how the parts interact will help in both maintenance and repair efforts.

Essential Maintenance Tips

Proper care is essential to keep the machine functioning optimally. Regular inspection and cleaning of the internal components are vital. Ensuring that moving parts are lubricated, and that the system is free from dust and debris, will significantly extend its lifespan and efficiency.