When dealing with home appliances, it is essential to grasp the function and structure of their internal mechanisms. This knowledge can significantly simplify troubleshooting and maintenance. Whether you’re fixing a malfunction or looking to improve performance, understanding how different components work together is the key to success.

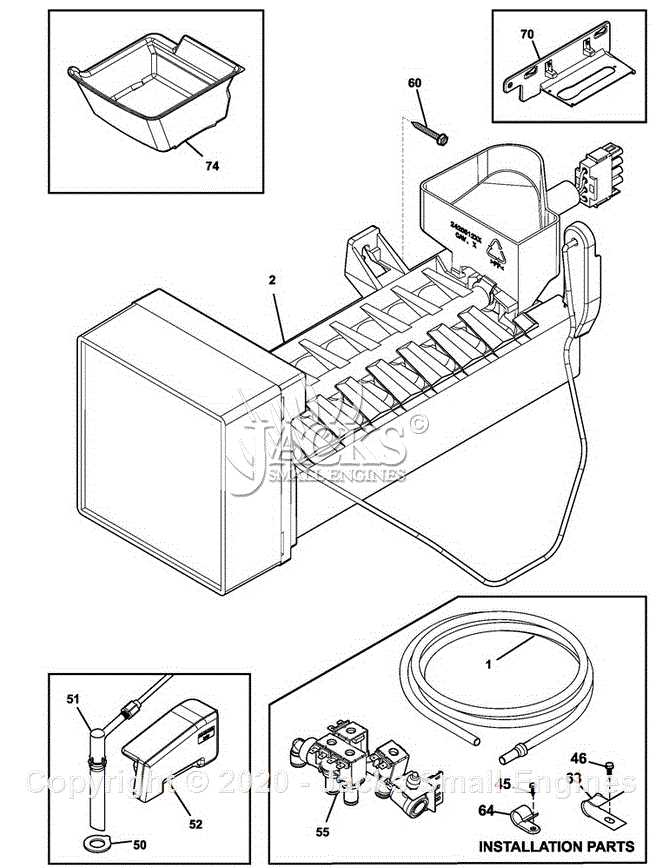

Visual aids and detailed references can help identify individual elements, making repairs more accessible. By familiarizing yourself with the layout and connections, you can ensure everything is functioning as intended.

In this guide, we will break down the major components, their roles, and offer step-by-step instructions to help you navigate repairs with ease. Understanding these features not only helps in fixing issues but also contributes to extending the life of the appliance.

Understanding GE Ice Maker Components

When working with appliances that generate frozen products, it’s crucial to understand how each component contributes to the overall function. These systems rely on a series of interconnected elements that work together to deliver consistent performance. Identifying each element’s role allows for more effective troubleshooting and maintenance.

Each individual unit within the system plays a specific part in the freezing and dispensing process. From the water inlet to the dispensing mechanism, each component must be in top condition for optimal operation. A well-maintained setup ensures efficiency and reduces the risk of breakdowns.

Familiarity with the internal structure of the appliance not only aids in fixing problems but also helps with preventive care. Knowing which parts interact and how they function together will guide you through necessary repairs or adjustments, making the process smoother and more efficient.

Common Issues with GE Ice Maker Parts

Over time, certain issues tend to arise with home appliance systems that produce frozen goods. These problems often stem from wear and tear or improper function of specific components. Identifying and addressing these issues early can save you time and money on repairs.

A frequent issue is inadequate water flow, which can lead to improper freezing or a complete lack of production. This often happens when the water inlet valve is malfunctioning or clogged. Similarly, mechanical failures in the dispensing mechanism may prevent the system from properly delivering the frozen items when needed.

Another common problem is the buildup of ice within the internal structure, which can block essential pathways and disrupt normal operation. This can occur due to a malfunctioning thermostat or a misaligned component, causing temperature irregularities.

How to Replace Ice Maker Parts Effectively

Replacing malfunctioning components within frozen goods production systems requires careful attention to detail and methodical steps. Effective replacement ensures the appliance returns to peak performance without unnecessary damage or complications. Understanding the right procedures is crucial for smooth repairs.

Step-by-Step Guide to Replacing Components

Begin by disconnecting the appliance from its power source to ensure safety. Once this is done, locate the faulty component, usually indicated by irregular functioning. Carefully remove any surrounding components that may obstruct access to the damaged part, taking note of their order for proper reassembly.

Proper Installation and Testing

Install the new component with precision, ensuring it is securely connected and aligned. After installation, reconnect the appliance and test its operation to confirm that the issue has been resolved. Make sure to check for any unusual sounds or irregularities during this test run to ensure everything is working as expected.