For those working with heavy machinery, a clear understanding of its inner workings is crucial. Knowledge of individual elements that make up the system helps to identify problems, perform efficient repairs, and ensure proper functioning over time.

In this article, we will break down the structure of a specific model’s mechanical assembly. We’ll provide a clear representation of its components, their roles, and how they work together. This will serve as a reference for both maintenance professionals and enthusiasts alike.

Additionally, we will explore common issues that may arise within these mechanisms and provide practical tips for troubleshooting and upkeep. Whether you’re a seasoned mechanic or a new user, this guide will help you enhance your technical understanding and improve the lifespan of your machinery.

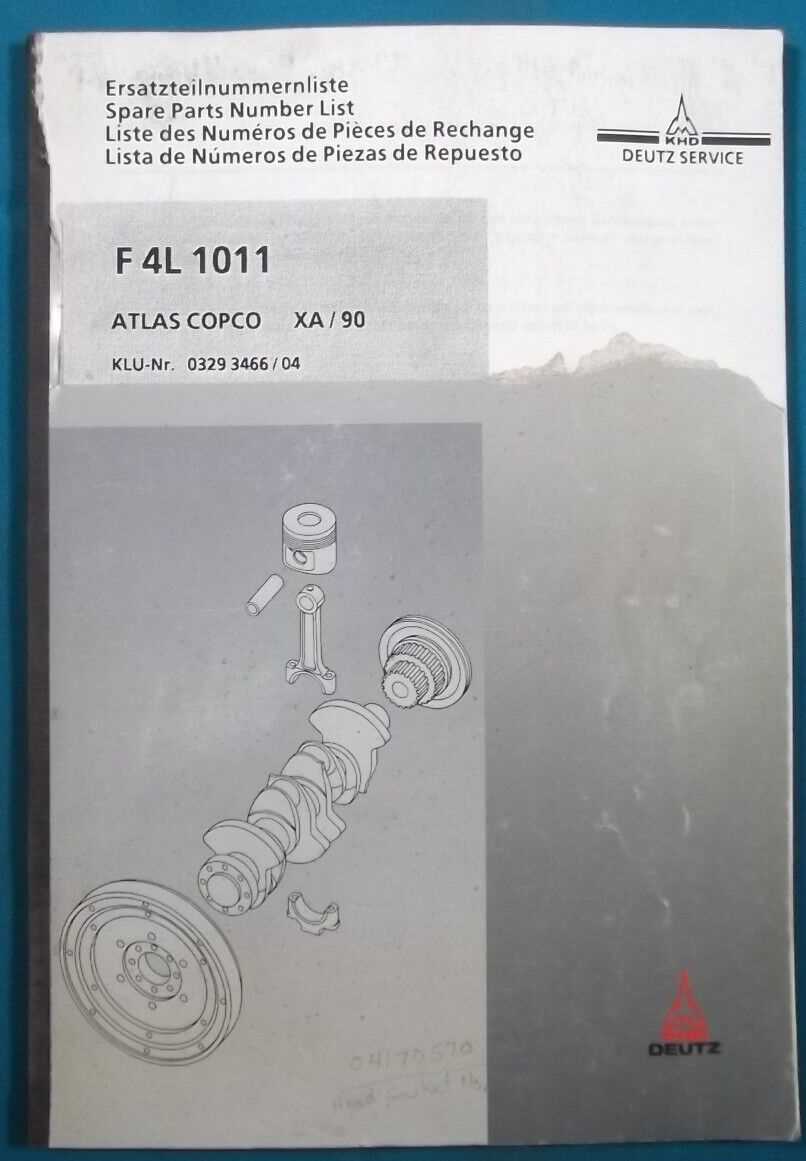

Understanding the Deutz 1011 Engine Parts

To fully grasp the mechanics behind a complex system, it’s important to examine the individual components and their functions. Each element plays a specific role in maintaining the overall performance, and understanding how they interact is essential for effective troubleshooting and repair.

In this section, we will delve into the core pieces that make up the machinery. From the power source to the transmission, each part works in harmony to ensure the unit runs smoothly. Whether you are a mechanic or a user, recognizing these elements will help you gain a deeper understanding of how the system operates and how to care for it properly.

We will also highlight the essential features of key components, explaining their function in simple terms. By learning how each part contributes to the machinery’s operation, you’ll be better equipped to address any potential issues and maintain optimal performance over time.

Detailed Diagram of Deutz 1011 Components

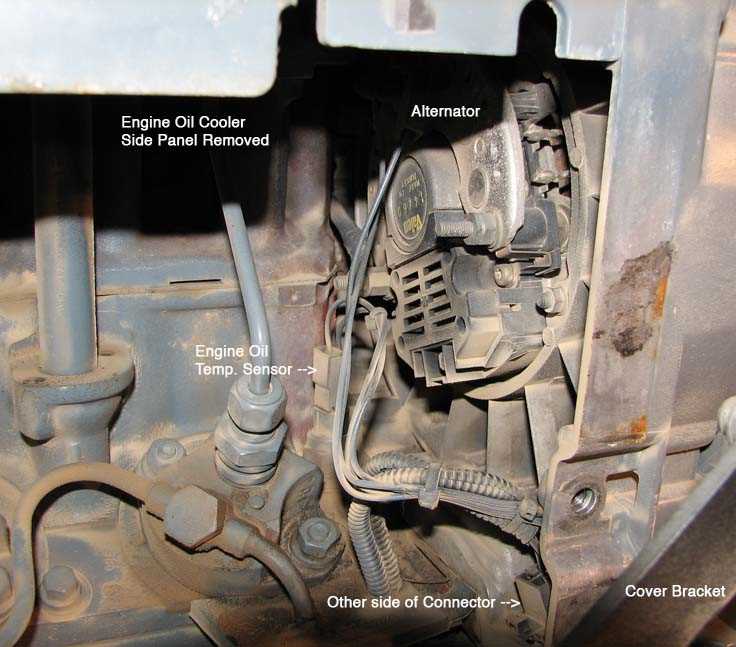

A visual representation of the system’s key elements allows for a clearer understanding of its internal structure. By examining how each piece is positioned and interconnected, one can better appreciate the overall design and functionality of the machinery.

This section provides an in-depth look at the various components, showcasing their locations and relationships within the system. With an accurate breakdown, users can identify parts more easily during maintenance and repairs, ensuring a smoother workflow and faster issue resolution.

Understanding these illustrations not only simplifies the process of recognizing worn or faulty components but also aids in troubleshooting. By referring to the detailed layout, it’s easier to spot potential problems and take corrective action before they lead to more serious damage.

Common Issues and Maintenance Tips for Deutz 1011

Like any complex system, regular upkeep and attention to potential problems are crucial to ensure long-term functionality. By addressing common faults early and following proper maintenance guidelines, you can avoid costly repairs and improve the machine’s performance.

Frequent Problems and Their Causes

One common issue with heavy machinery is overheating, often caused by insufficient cooling or clogged systems. Another frequent problem is air or fuel filter blockage, which can reduce efficiency and cause operational disruptions. It’s essential to monitor these elements regularly and replace them when necessary to maintain optimal functionality.

Routine Maintenance and Preventative Measures

To keep the system in top condition, regular servicing is key. Changing filters, lubricating moving parts, and ensuring that all connections are tight and free of debris should be part of any maintenance schedule. Additionally, periodic inspections of belts, seals, and hoses will help identify potential leaks or wear before they cause larger issues.