Maintaining and repairing farm machinery requires a solid understanding of the individual components that make up each piece of equipment. Knowing how the different parts work together can help you troubleshoot issues and ensure proper functionality. This section focuses on the essential parts that are critical for smooth operation and how to identify them effectively.

Farm equipment often consists of complex mechanical systems with various interconnected elements. Whether you are performing regular maintenance or addressing a specific malfunction, having a clear visual guide and knowledge of each part’s role is invaluable. With proper identification, repairs become more manageable and can be done efficiently.

In this guide, we’ll explore the common components, how to interpret their structure, and what to look for when diagnosing problems. Whether you are a beginner or experienced technician, the right approach to understanding these mechanisms will help you keep your machinery in top condition.

Understanding John Deere 640 Rake Components

Every piece of agricultural machinery consists of several key elements that work in tandem to ensure efficient operation. Each component plays a specific role, and understanding their functions can help maintain the equipment’s performance. In this section, we will break down the critical components of the machine, focusing on their structure, purpose, and interaction with one another.

At the core of any piece of equipment is the system of gears, arms, and wheels that allow the machine to perform its task effectively. These mechanisms interact through a series of adjustments, ensuring that all parts operate smoothly. Identifying and understanding these components will give you the ability to spot potential issues before they affect performance, reducing downtime and repair costs.

By learning the layout of these elements and their connections, you can also improve your approach to repairs. Knowing where each component fits and how it functions will allow you to quickly identify malfunctioning parts and address them appropriately, ensuring that the equipment remains reliable and effective for its intended use.

How to Read the Parts Diagram

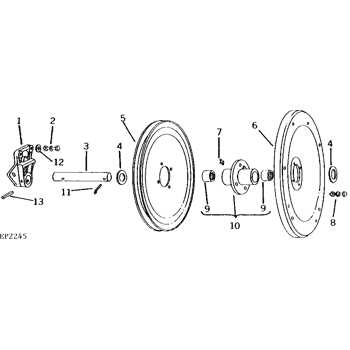

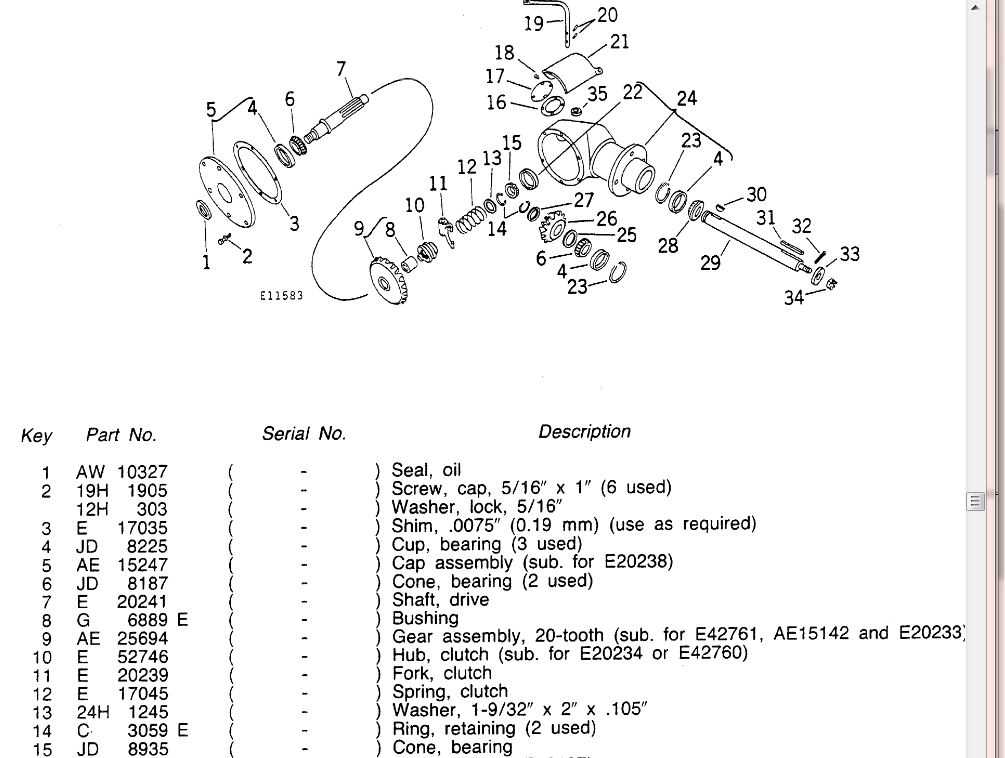

Understanding the layout of a mechanical system is essential when it comes to maintenance and repair. A visual guide showing all components can help you quickly identify each part and its specific role within the machine. This guide will walk you through the process of interpreting such illustrations, making it easier to troubleshoot and maintain the equipment.

When examining the guide, pay close attention to the numbers and labels assigned to each component. These references will allow you to cross-check parts with their corresponding inventory lists, ensuring that you order the correct replacements. In addition, understand how each element connects to others; this knowledge helps in visualizing how adjustments to one part might affect the overall system.

One of the most important aspects of reading these visual guides is recognizing the level of detail provided. Some illustrations may offer a close-up view of specific parts, highlighting smaller, more intricate elements. Understanding these finer details can be crucial for identifying wear, tear, or potential failures that may not be immediately obvious.

Common Repairs for John Deere 640 Rake

Like any heavy machinery, agricultural equipment requires regular maintenance to ensure it operates smoothly. Over time, certain components can wear out, and addressing these issues promptly can prevent further damage and downtime. This section highlights some of the most common repairs that may be necessary for keeping your equipment in peak working condition.

The following are typical repairs that are often needed:

- Wheel and Tire Replacement: Wheels can wear down due to constant movement over rough terrain. Replacing worn tires or adjusting wheel alignment can help improve efficiency.

- Drive Mechanism Maintenance: The drive system may experience wear on gears and chains, leading to poor performance. Regular lubrication and timely part replacements can prevent more significant problems.

- Linkage and Arm Adjustments: The linkage and arm systems often require adjustments or replacements due to stress over time, which can affect the machine’s function.

- Hydraulic System Checks: Leaking hoses or malfunctioning hydraulic cylinders can lead to decreased power and control. Regular inspections are key to preventing fluid loss and ensuring optimal function.

- Cleaning and Replacing Tines: Over time, tines may become bent or damaged. Cleaning or replacing them as needed ensures the equipment performs at its best.

By staying on top of these common repairs, you can extend the lifespan of your machine and avoid more costly repairs down the line. Regularly reviewing your machine’s performance and addressing small issues early will contribute to its overall reliability and productivity.