When maintaining or repairing small engines, having a clear understanding of their components and how they fit together is crucial. Detailed illustrations can serve as invaluable tools for anyone working with these machines, from professionals to hobbyists. By referring to such resources, individuals can ensure accurate repairs and replacements, minimizing the risk of errors that could affect the engine’s performance.

Identifying specific parts and understanding their functions will help streamline the repair process. Whether you are troubleshooting a malfunction or performing routine maintenance, knowing the exact placement and connection of each component is essential. Access to these detailed visuals allows for more efficient diagnostics, saving both time and effort during repairs.

Proper knowledge of these diagrams not only helps with repairs but also supports better engine care, increasing its lifespan and ensuring smooth operation for years to come. This guide aims to provide a clear and accessible way to navigate engine components, making it easier to handle any necessary maintenance or fixes.

Understanding the Engine Components

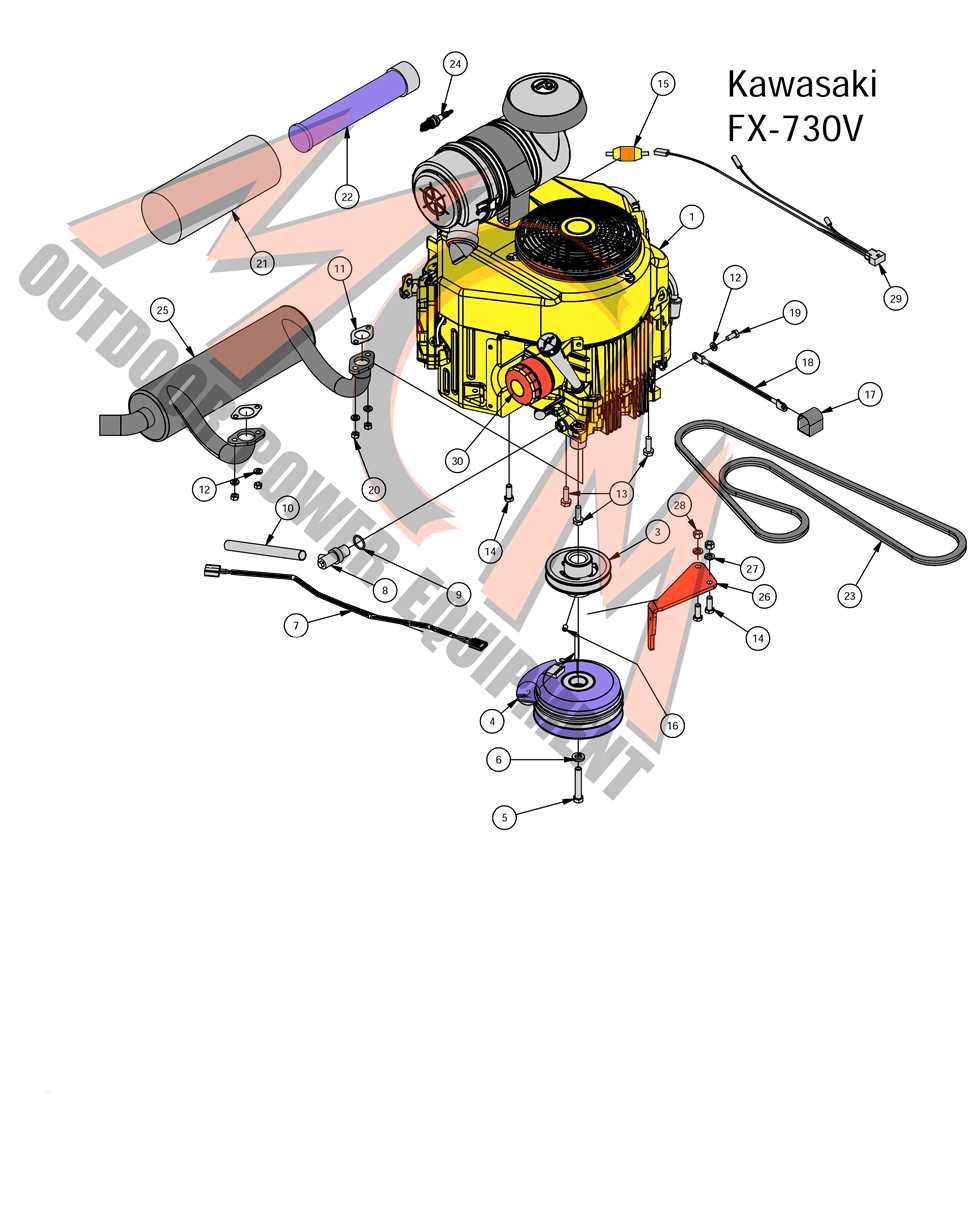

To effectively maintain or repair small engines, it is essential to familiarize oneself with the various components that make up the machinery. Each piece plays a specific role, and understanding their function allows for accurate diagnostics and efficient repairs. By knowing how the engine operates as a whole, individuals can identify where problems may arise and address them quickly.

Key elements such as the ignition system, fuel delivery system, and cooling mechanism are vital to the engine’s overall performance. Understanding how these parts interact ensures that each component is properly maintained or replaced when needed. Whether it’s the carburetor, air filter, or valves, recognizing the importance of every part contributes to the longevity and smooth functioning of the engine.

Recognizing common wear and tear in individual components also helps in preventing more severe issues. Regular inspection of critical parts ensures early detection of potential malfunctions, making it easier to carry out timely repairs. Knowledge of these components is an invaluable resource for anyone looking to keep their engine running smoothly and efficiently for years.

How to Read the Parts Diagram Effectively

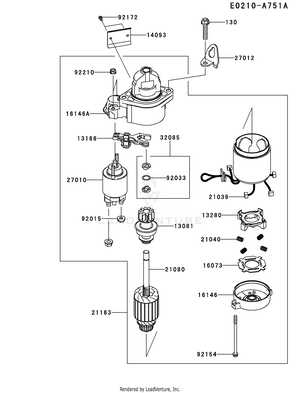

Interpreting technical illustrations for engine components can be a crucial skill when performing repairs or maintenance. These visuals provide a clear layout of how each part fits together, allowing you to identify, replace, or troubleshoot specific components. However, understanding the structure and layout of these images is key to using them effectively. Knowing where to start and what to focus on will make the repair process smoother and faster.

Identify the Key Sections

The first step is to familiarize yourself with the different sections of the illustration. Typically, components are grouped based on their function, such as the fuel system, ignition system, or cooling system. Understanding these categories helps you to focus on the relevant area of the engine, narrowing down where problems may exist and where to begin your work.

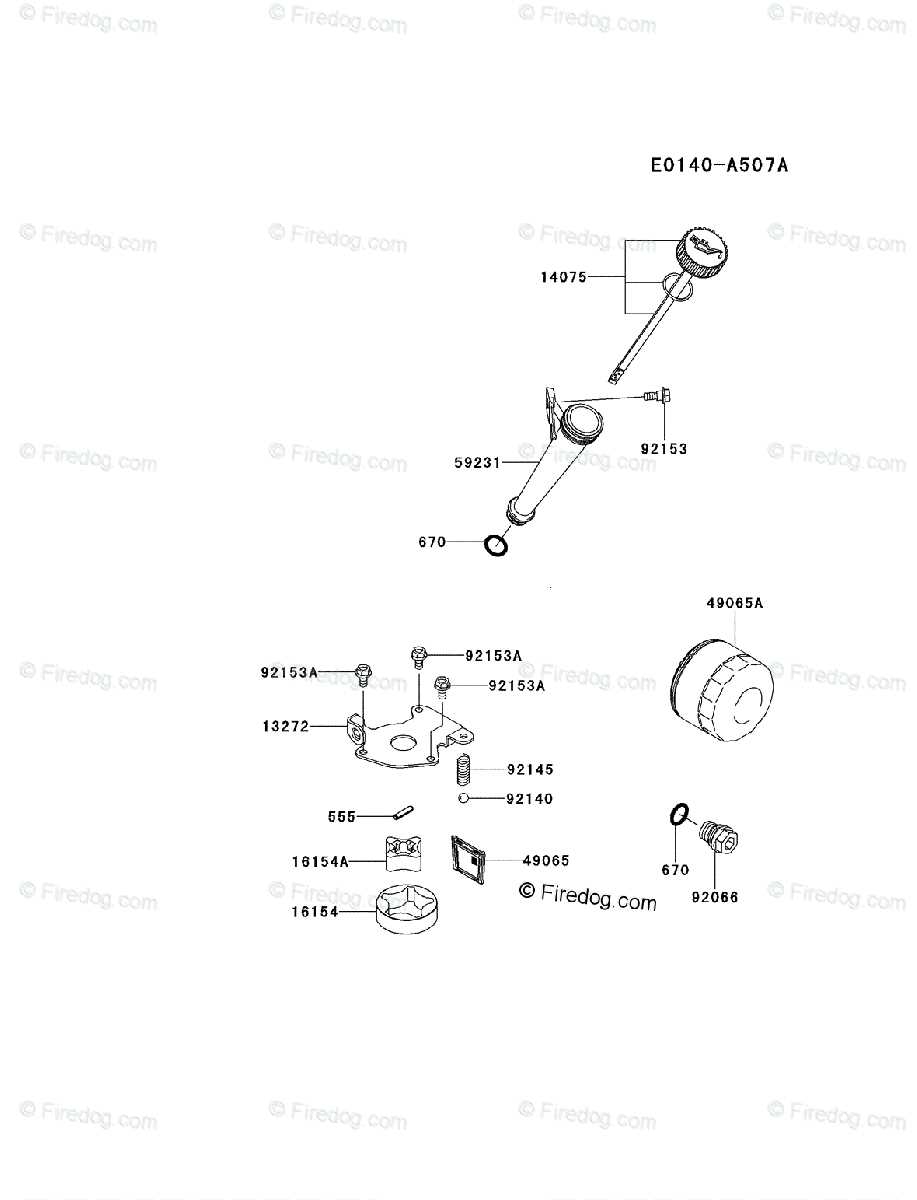

Understand Part Numbers and Labels

Another important element in these illustrations is the part numbering system. Each component is typically labeled with a unique identifier, which corresponds to a detailed list of parts. This allows you to quickly find replacements or verify that you have the correct component. Pay close attention to these labels as they can save time during both the ordering process and actual repairs.

Common Issues and Replacement Parts for Small Engines

Engines, like any mechanical system, are prone to wear and tear over time. Regular maintenance is essential to prevent common issues, but even with proper care, certain components may require replacement due to malfunction or damage. Recognizing these common problems early on can help in making repairs before more significant damage occurs. Understanding which parts need attention and knowing the appropriate replacements is key to ensuring the engine continues to perform optimally.

Some of the most frequent problems faced by engine owners include:

- Fuel system blockages: Clogged fuel filters or lines can cause reduced engine performance or complete failure to start.

- Ignition system failures: Worn spark plugs or ignition coils may lead to difficulty starting or misfires.

- Overheating: A damaged cooling system, often due to a faulty radiator or cooling fan, can lead to engine overheating.

- Air intake problems: Dirty or clogged air filters can restrict airflow, causing the engine to run inefficiently.

To address these issues, consider replacing the following components:

- Fuel filter and fuel lines

- Ignition coil and spark plugs

- Cooling fan or radiator

- Air filter

By proactively replacing damaged or worn components, you can extend the life of your engine and avoid costly repairs down the line. Regular inspection and timely replacement are essential for smooth operation and peak performance.