Understanding the layout and functions of various machine elements is crucial for maintenance and repair. Whether you’re tackling minor fixes or preparing for more significant restoration work, knowing each component’s role is essential. A clear reference can simplify the process and ensure the longevity of your equipment.

In this guide, you’ll find detailed insights into the key parts that make up the system, offering you a comprehensive visual and practical understanding. This will help you identify, troubleshoot, and replace the right pieces when needed, preventing unnecessary confusion and downtime.

Step-by-step instructions and helpful visuals are provided to assist with both identification and installation of the necessary components. Whether you are a novice or an experienced technician, this resource will improve your ability to handle the task at hand with confidence.

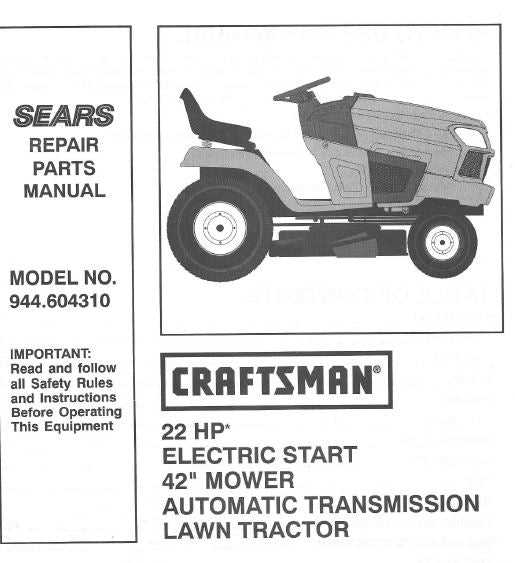

Understanding Craftsman M260 Components

Every piece of outdoor machinery consists of several essential elements that work together to ensure smooth operation. Understanding how these components fit and function within the overall system is crucial for both maintenance and repair. This knowledge enables users to handle troubleshooting, part replacement, and routine servicing with ease.

Main Assembly of the Equipment

The main structure of the machine supports all other components and provides stability during operation. It houses key mechanisms like the engine and drive system, which are responsible for generating and transferring power. Each part within this assembly is connected and synchronized to function seamlessly, making it essential to maintain the integrity of the overall structure for optimal performance.

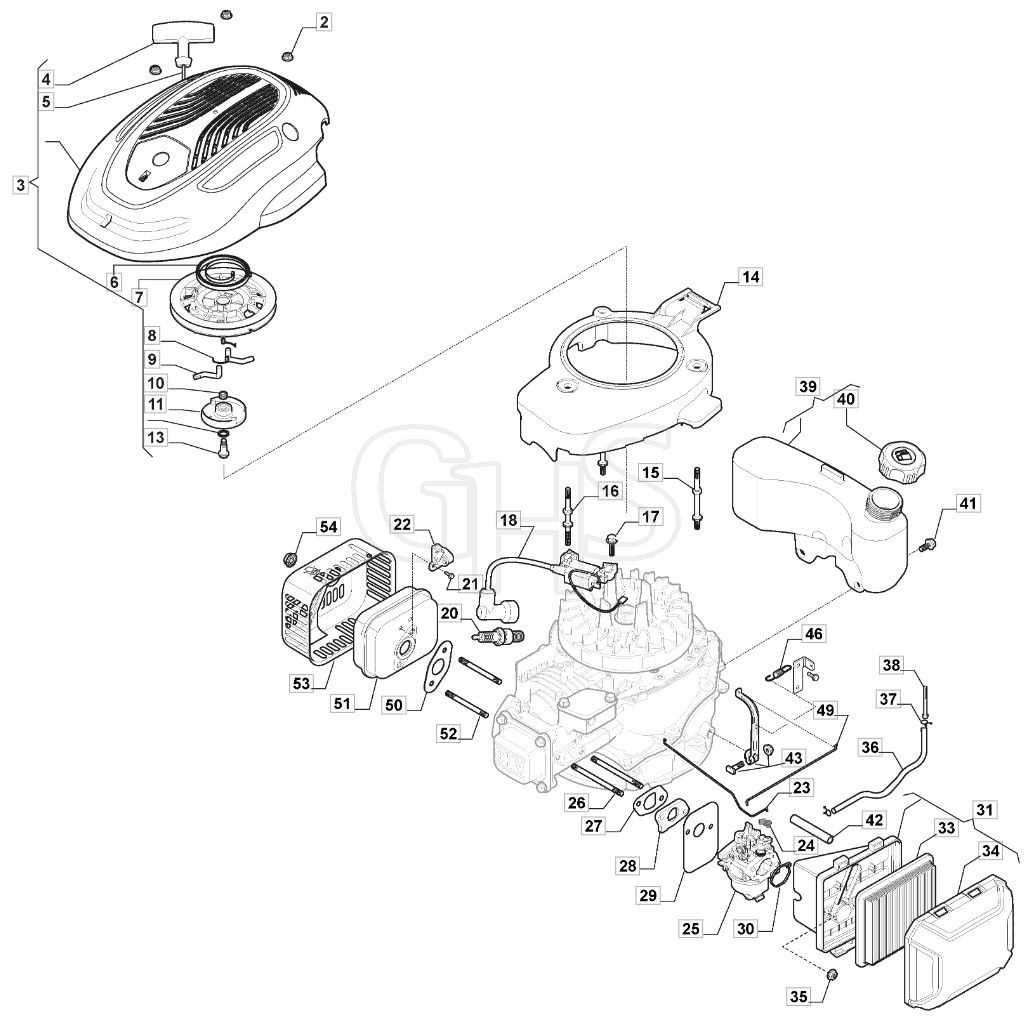

Power and Drive Mechanisms

The power system is at the heart of any machinery, converting energy into motion. In this case, the engine generates the force required to move the components, while the drive system ensures that power is transferred effectively to the working parts. Regular inspection and maintenance of these critical systems can prevent malfunctions and improve the machine’s efficiency.

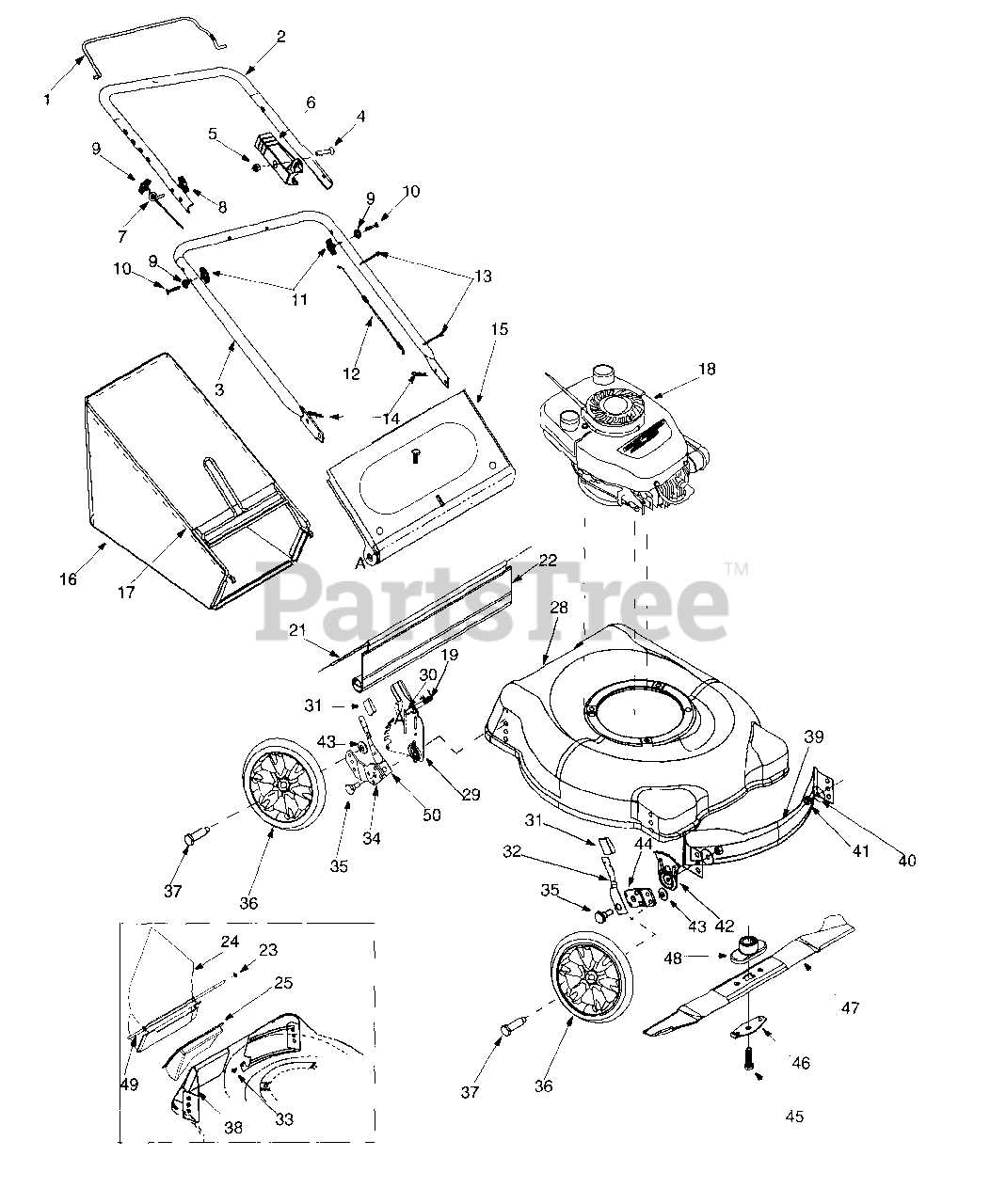

Identifying Key Parts for Repair

Properly identifying the malfunctioning components of a machine is the first step toward effective repair. Recognizing which parts need attention can save time and effort, allowing for targeted maintenance. When a machine stops functioning as expected, understanding the core elements that typically wear out or become damaged is essential for quick resolution.

Commonly Affected Components

Some parts are more prone to damage due to frequent use or environmental exposure. The engine components, belts, and transmission systems are often the first to show signs of wear. Inspecting these areas can help pinpoint common issues that may hinder performance. Regular checks of these critical components can prevent major breakdowns and costly repairs.

Tools for Accurate Identification

Having the right tools at hand is key to accurately diagnosing the problem. A detailed reference guide and diagrams can help compare parts visually, while a basic set of tools such as wrenches and screwdrivers allows for hands-on inspection. Using these resources ensures that repairs are both effective and efficient, minimizing downtime and maintaining the overall functionality of the machine.

Step-by-Step Assembly and Disassembly

Understanding the process of assembling and disassembling outdoor machinery is critical for effective maintenance and repair. Breaking down each step carefully allows you to troubleshoot issues and replace damaged elements without compromising the overall functionality. A methodical approach to both assembly and disassembly ensures that each component is properly handled and reinstalled correctly.

Start by carefully laying out all components before beginning the assembly process. Follow the sequence of steps to ensure that no part is overlooked and that connections are secure. For disassembly, it’s important to reverse the assembly steps in a controlled manner, keeping track of screws, bolts, and fasteners to avoid losing any pieces. Proper organization during this process minimizes the risk of damage and ensures a smooth reassembly.